120 MS 441, MS 441 C

Always check and clean the tank

vent in the event of trouble with the

carburetor or fuel supply system,

replace if necessary. Check function

by testing the fuel tank under

vacuum or at gauge pressure via

the fuel hose.

– Open fuel filler cap and drain fuel

tank.

Collect fuel in a clean container and

dispose of it in accordance with

environmental regulations.

– Close fuel filler cap.

– Remove carburetor, b 14.3,

before checking function via fuel

hose.

Work through the following steps

and repeat the test if a leak is found.

– Remove carburetor housing,

b 14.6.2.

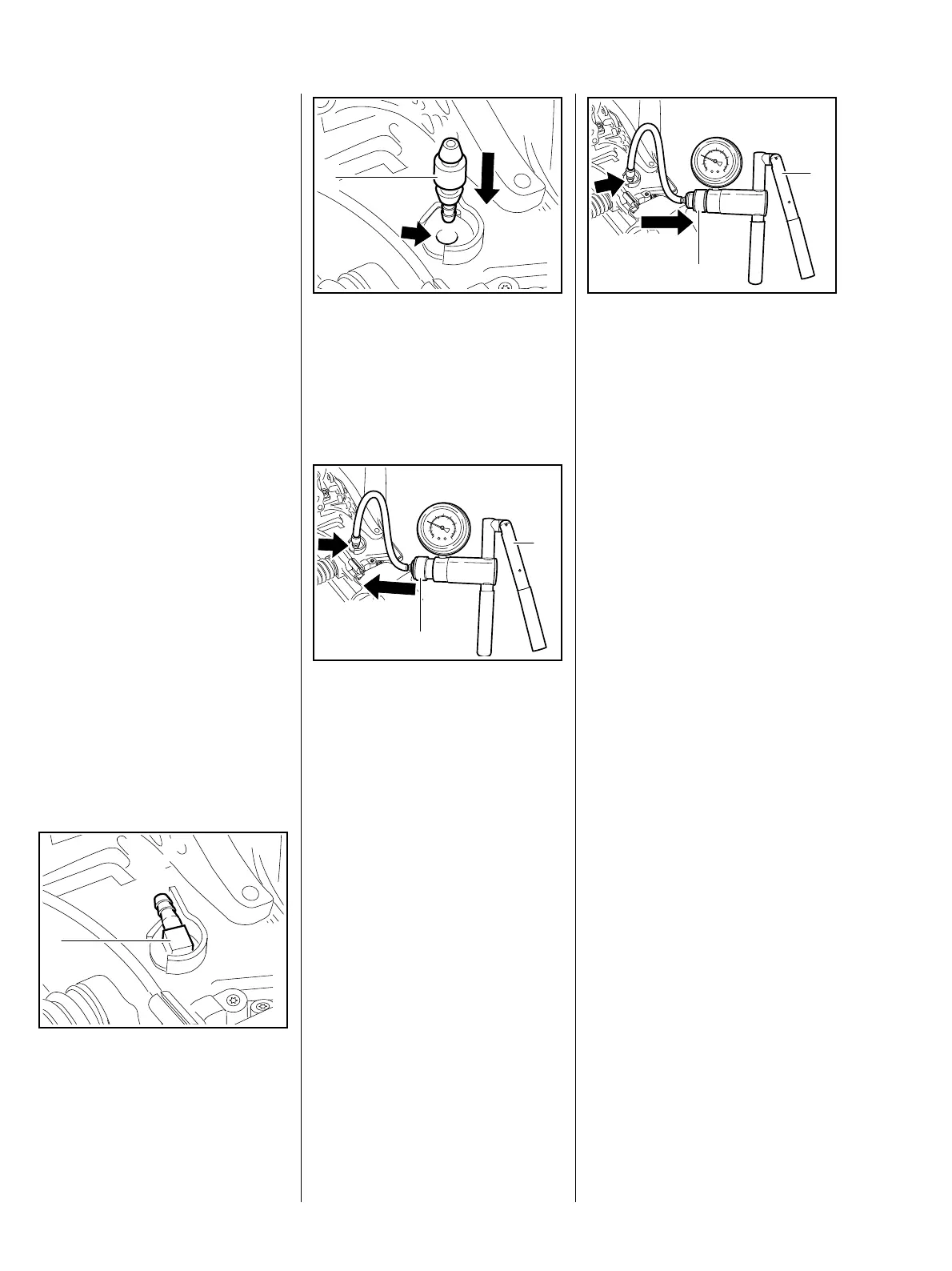

: Pull out elbow connector (1).

219RA535 TG

1

: Push nipple (1)

0000 855 9200 into flange

(arrow) of intake hose.

219RA536 TG

1

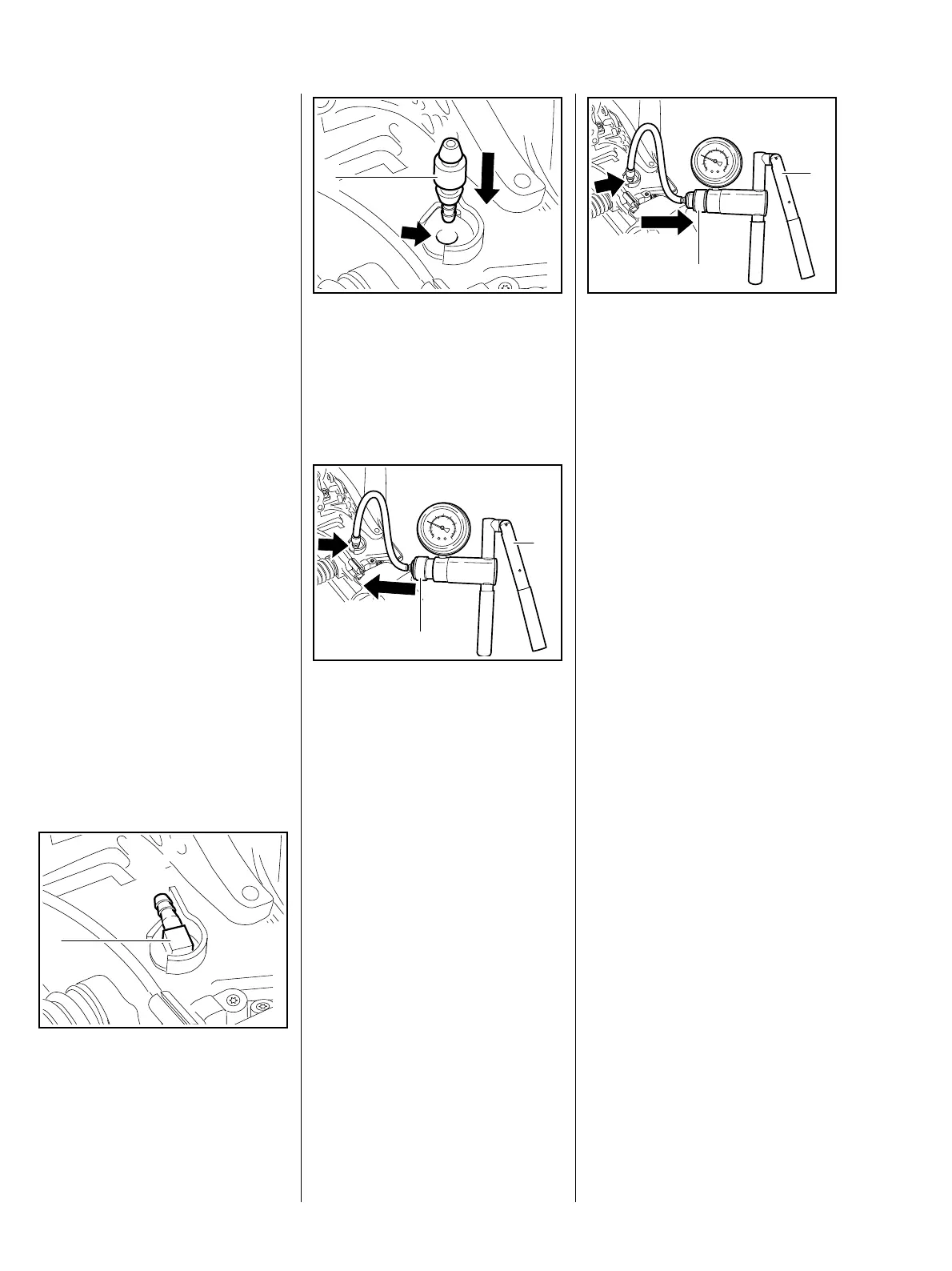

Vacuum test

: Slide ring (1) to the left and

connect pump (2) 0000 850 1300

to nipple (arrow).

Build up vacuum in fuel tank.

Equalization of pressure takes

219RA537 TG

1

2

place via the tank vent. A vacuum

must not build up in the tank.

– Clean area around the tank vent.

– Replace tank or tank vent if

necessary, b 14.7 or b 14.8.4.

Pressure test

: Slide ring (1) to the right and

connect pump (2) 0000 850 1300

to nipple (arrow). Build up

pressure in fuel tank.

– Actuate pump until pressure

219RA538 TG

1

2

gauge shows a reading of

0.5 bar. If this pressure is

maintained for at least

20 seconds, the tank and tank

vent are airtight. If the pressure

drops, the leak must be located

and the faulty part replaced.

– Reassemble in the reverse

sequence.

14.7 Tank vent

14.7.1 Check

Loading...

Loading...