27MS 441, MS 441 C

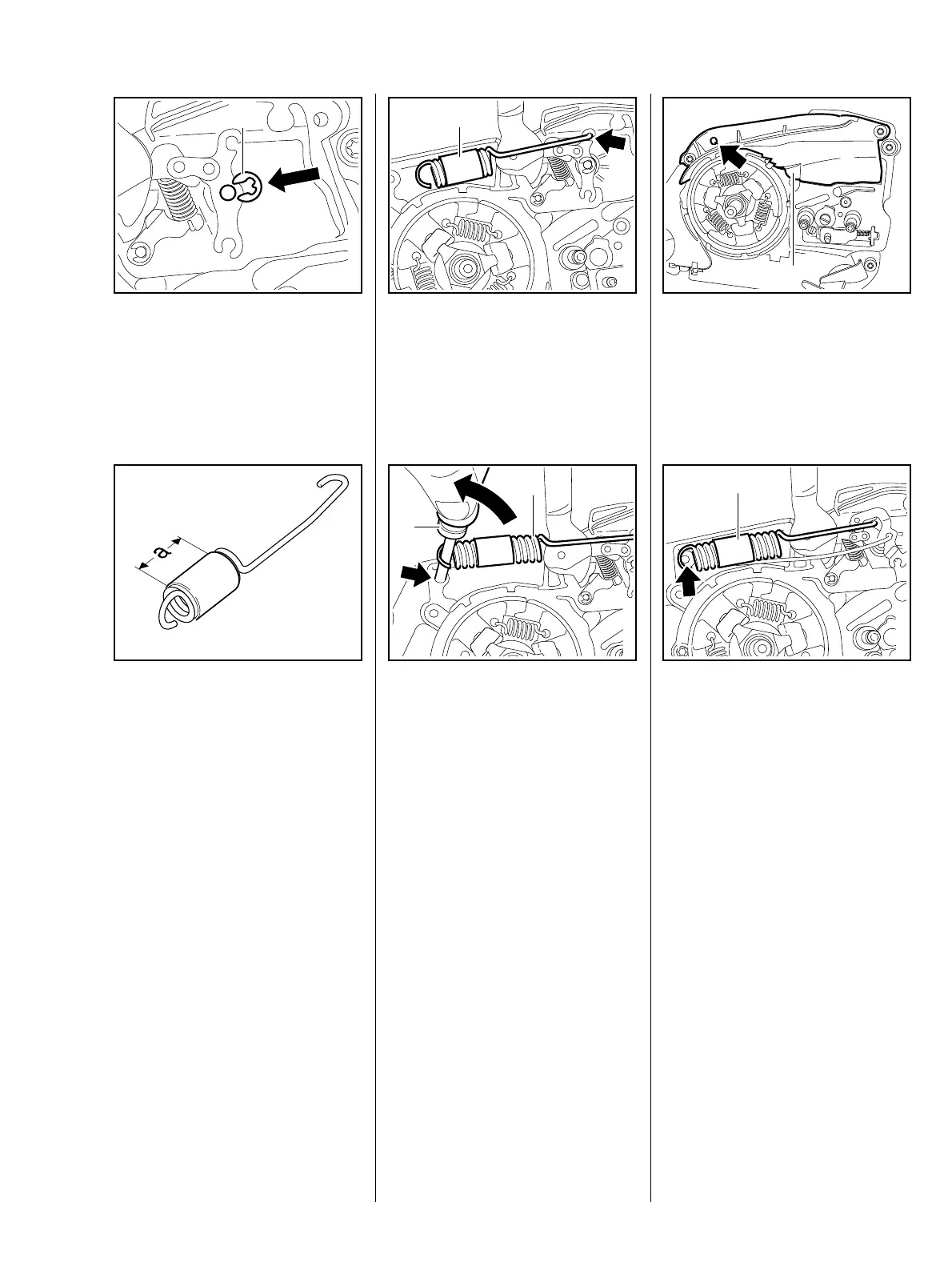

: Fit circlip (1).

219RA062 TG

1

: The turns of the brake spring

must be tightly spaced when not

installed; use a new brake spring

if necessary.

Check correct position of protective

tube: it must be centred on the

spring.

19RA063 TG

a = 20 mm

The pin for the brake spring must be

replaced if it shows signs of wear at

the groove, b 7.5.

: Hook brake spring (1) into brake

lever (arrow).

219RA064 TG

1

: Use assembly tool (2)

1117 890 0900 to attach brake

spring (1) to anchor pin (arrow).

– Reassemble all other parts in the

reverse sequence.

– Tightening torques, b 3.5.

219RA065 TG

1

2

– Grease brake lever, b 17.

The cover (1) on machines with

QuickStop Super is marked with the

letter "Q" (arrow).

219RA066 TG

1

– Troubleshooting chart, b 4.2.

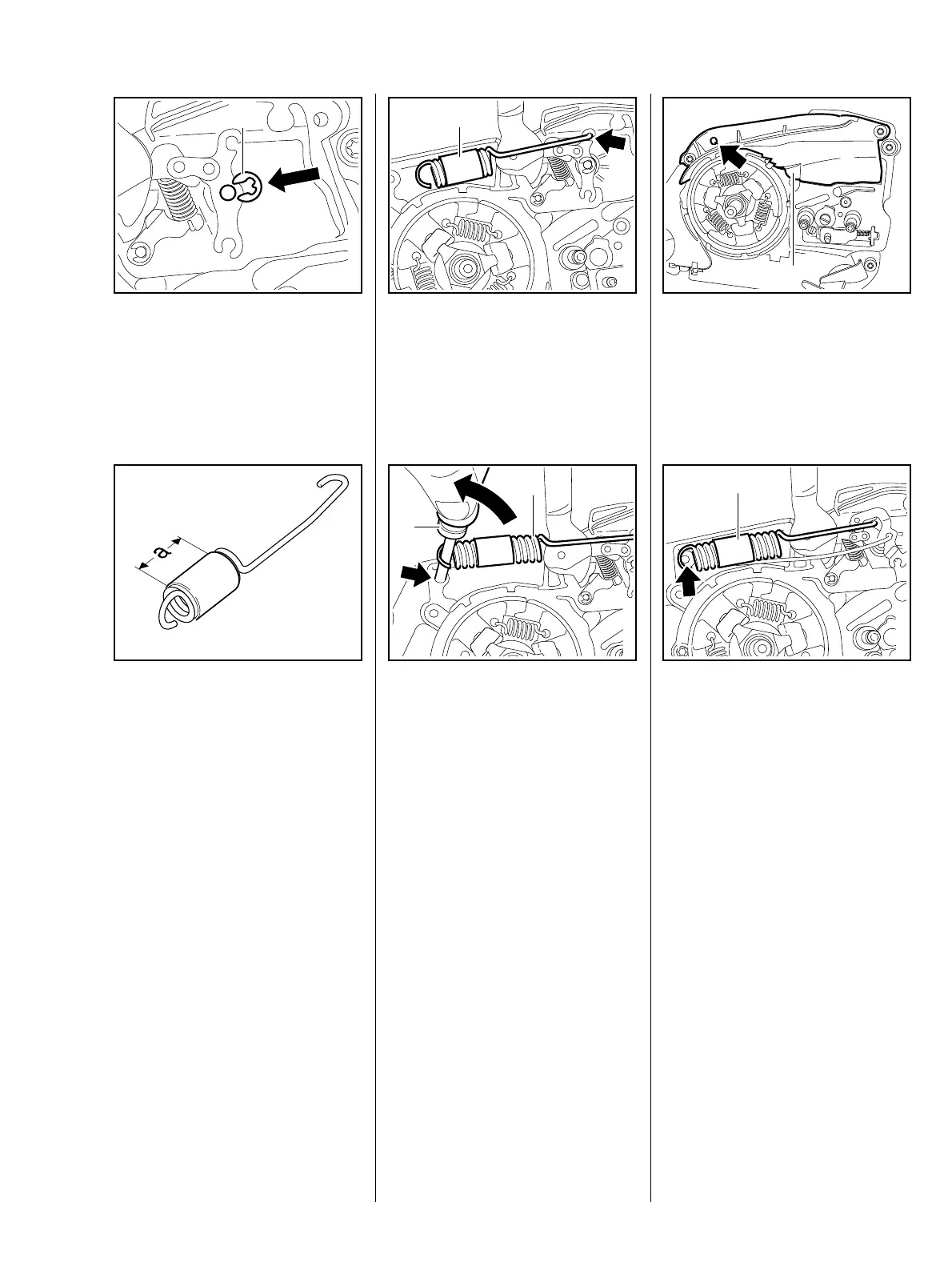

– Remove shroud, b 8.4.

– Remove brake band, b 7.1.

– Push hand guard towards chain.

219RA067 TG

1

– The brake spring is now relaxed.

: Ease brake spring (1) off anchor

pin (arrow).

: Unhook brake spring (1) from

brake lever.

7.3 QuickStop Super

brake lever

Loading...

Loading...