54 MS 441, MS 441 C

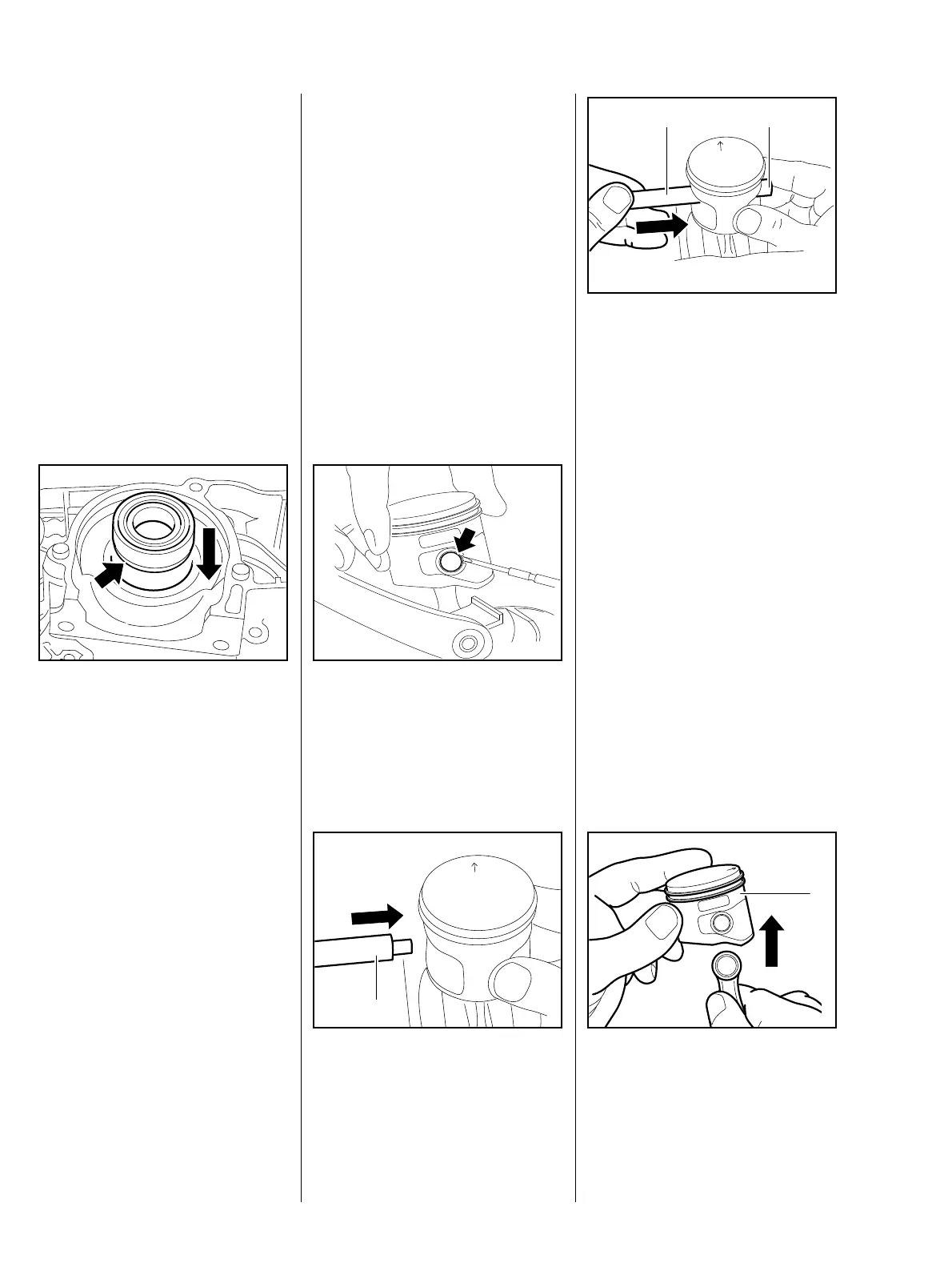

Since the crankcase half on the

clutch side does not have a fixed

bearing seat, the oil pump must be

installed. It then serves as

reference.

– Install oil pump, b 13.3.

– Heat area around bearing seat to

approx. 150 °C (300 °F).

– Position ball bearing so that the

centring ring (arrow) points

towards the oil pump.

: Press ball bearing fully home (oil

219RA143 TG

pump).

The ball bearing must be fitted

quickly as it absorbs heat and

expands.

– Remove oil pump, b 13.3.

– Install crankshaft, b 8.6.

– Install oil seals, b 8.3.

– Reassemble all other parts in the

reverse sequence.

– Tightening torques, b 3.5.

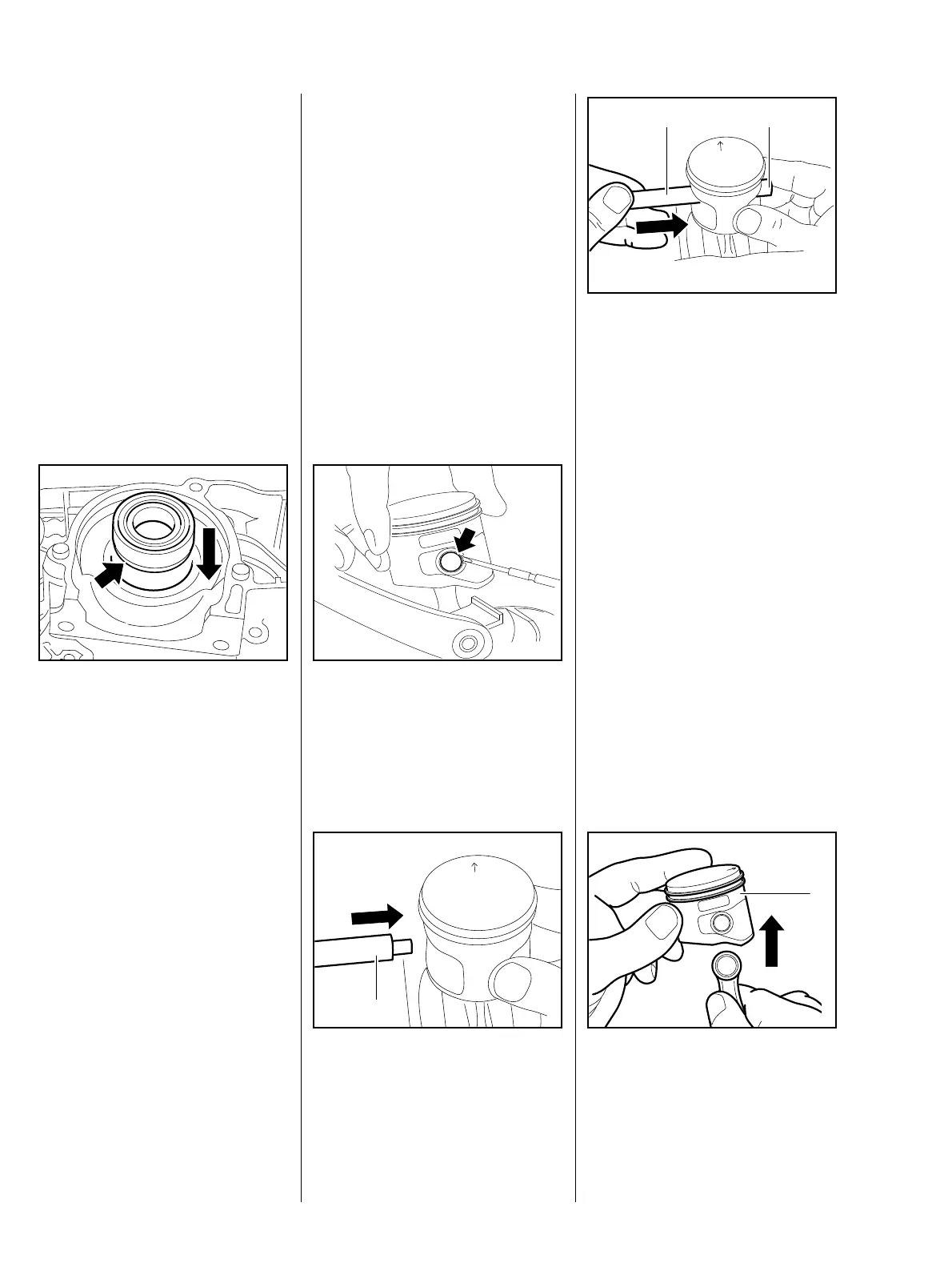

Before removing the cylinder,

decide whether the crankshaft is to

be removed, b 8.6.

– Remove cylinder, b 8.5.

: Prise hookless snap rings on

both sides out at the recess

(arrow) with a suitable tool.

: Apply assembly drift (1)

1111 893 4700.

1

: Push piston pin (1) out of the

piston with assembly drift (2)

1111 893 4700.

If the piston pin is stuck, it can be

loosened by lightly tapping the

assembly drift with a hammer. The

piston must be steadied during this

2 1

process to ensure that jolts are not

transmitted to the con-rod.

: Remove piston (1) from con-rod.

– Examine piston rings, replace

if necessary, b 8.8.

1

8.7 Piston

8.7.1 Removal

Loading...

Loading...