22 MS 441, MS 441 C

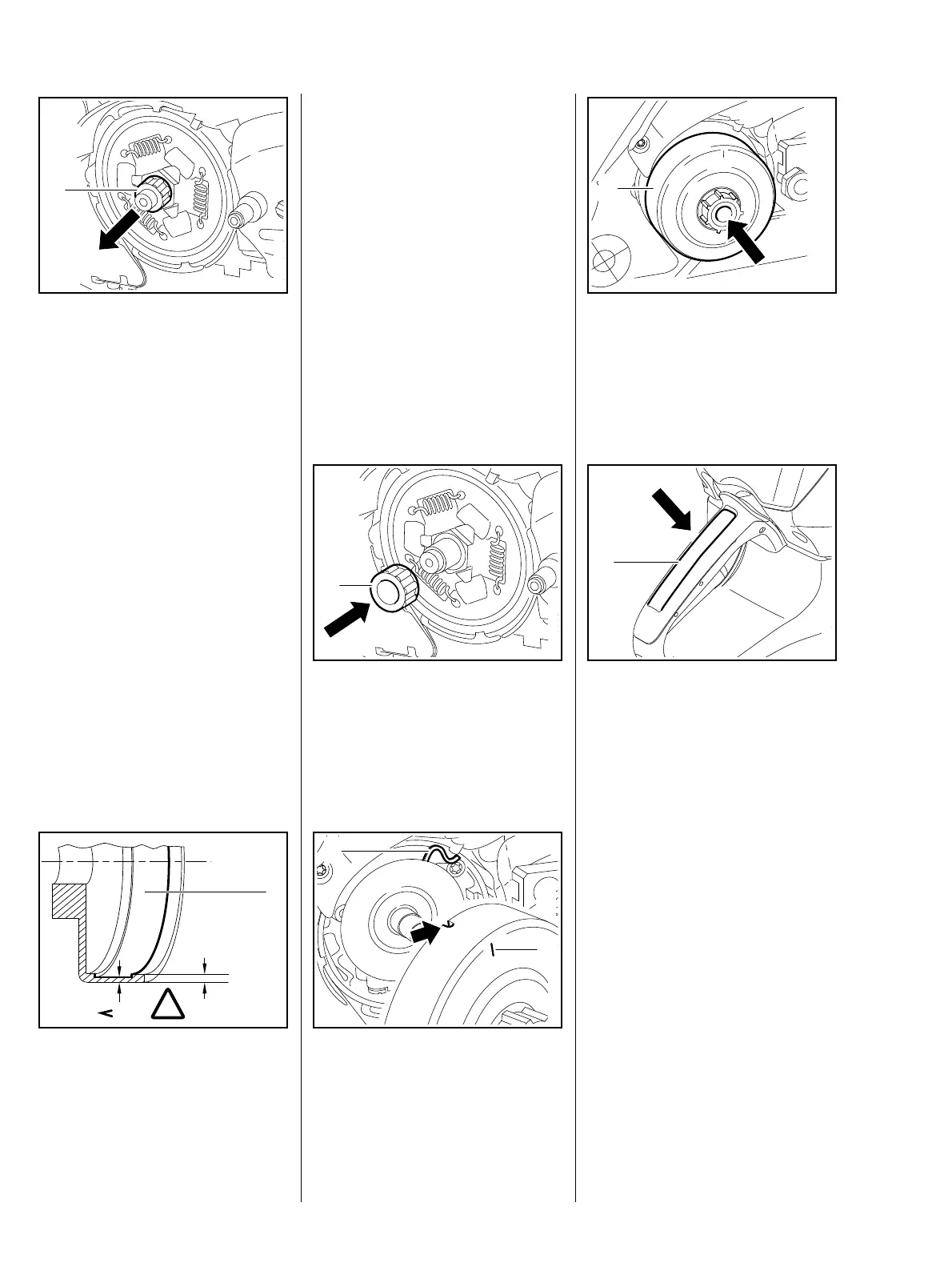

: Remove needle cage (1).

Clean the needle cage and

crankshaft stub with a little

commercially available solvent-

based degreasant not containing

any chlorinated or halogenated

hydrocarbons.

1

19RA035 TG

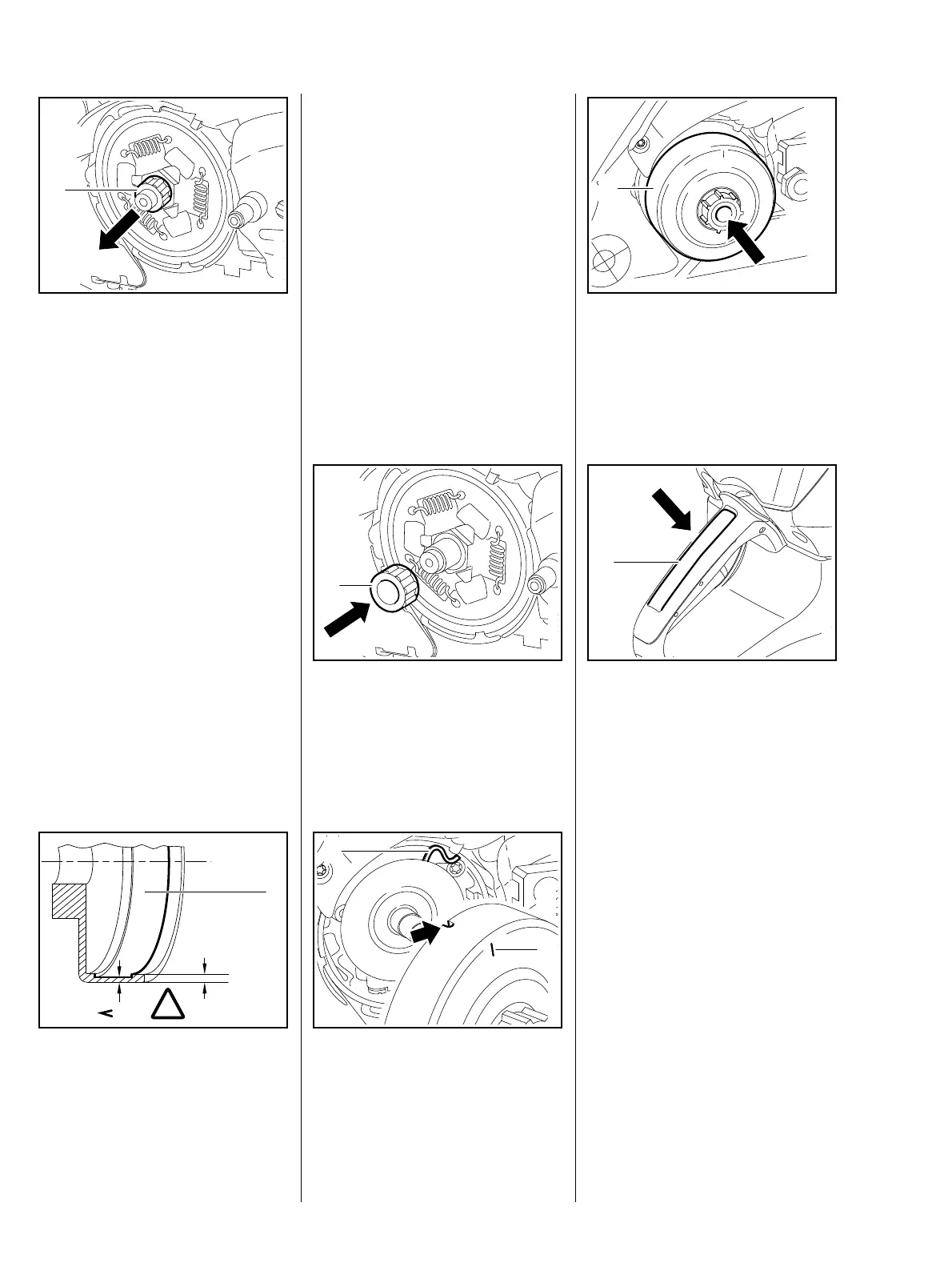

– Examine clutch drum (1) for signs

of wear.

If there are signs of serious wear on

the inside diameter of the clutch

drum (1), check the remaining wall

thickness. If it is less than about

80 % of the original thickness, fit

a new clutch drum.

– Reassemble in the reverse

sequence.

– Grease needle cage and

crankshaft stub, b 17.

: Push needle cage (1) onto the

crankshaft stub.

1

19RA036 TG

The notch (arrow) in the clutch drum

must engage the carrier (1) of the

wormwheel.

The mark (2) can be used for

guidance.

TOP

2

1

19RA037 TG

: Fit clutch drum (1).

19RA038 TG

1

Machines with QuickStop Super

Disengage the brake before fitting

the clutch drum.

: Press and hold the trigger

interlock (1).

1

19RA034 TG

– Fit clutch drum.

Loading...

Loading...