083730300A DCN8101 Getting Started 41

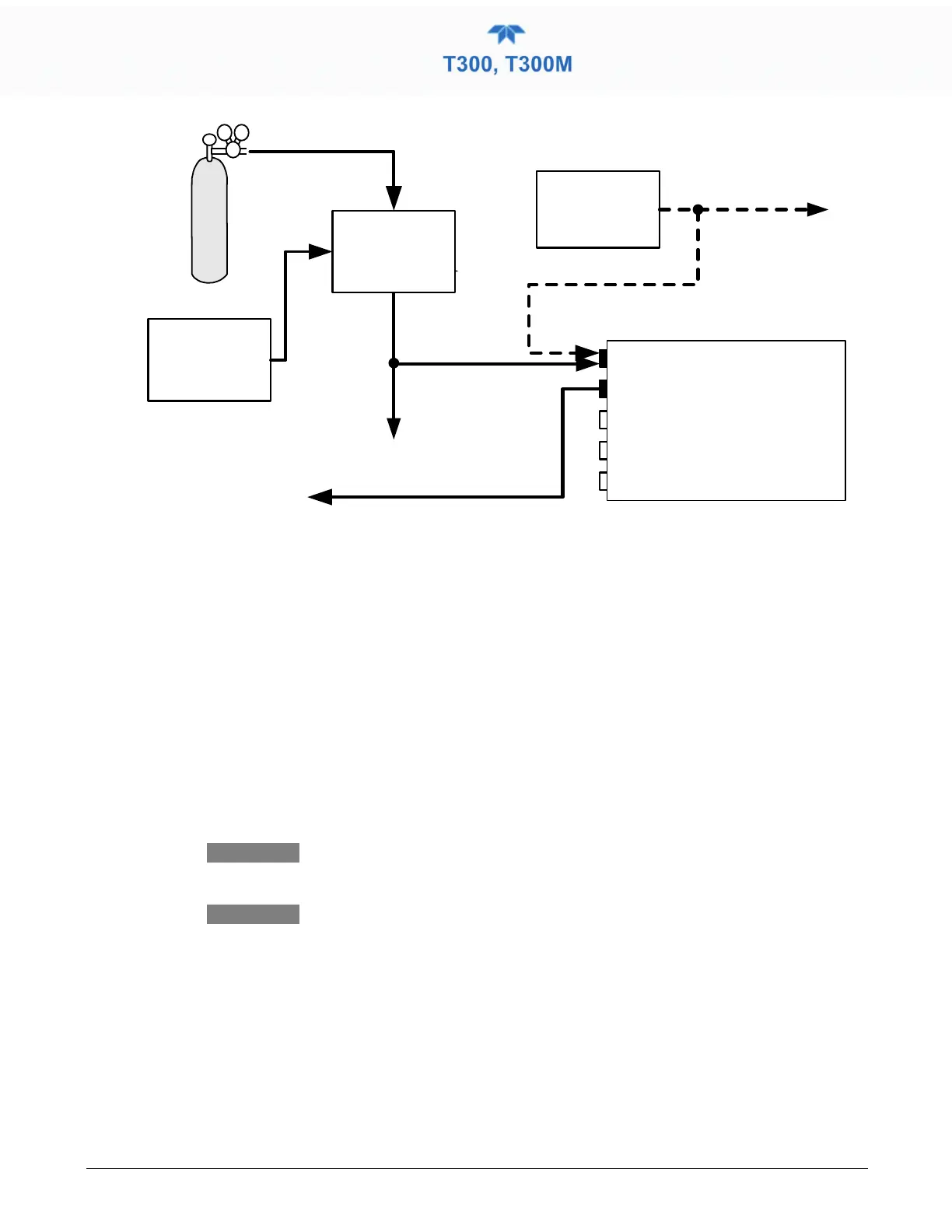

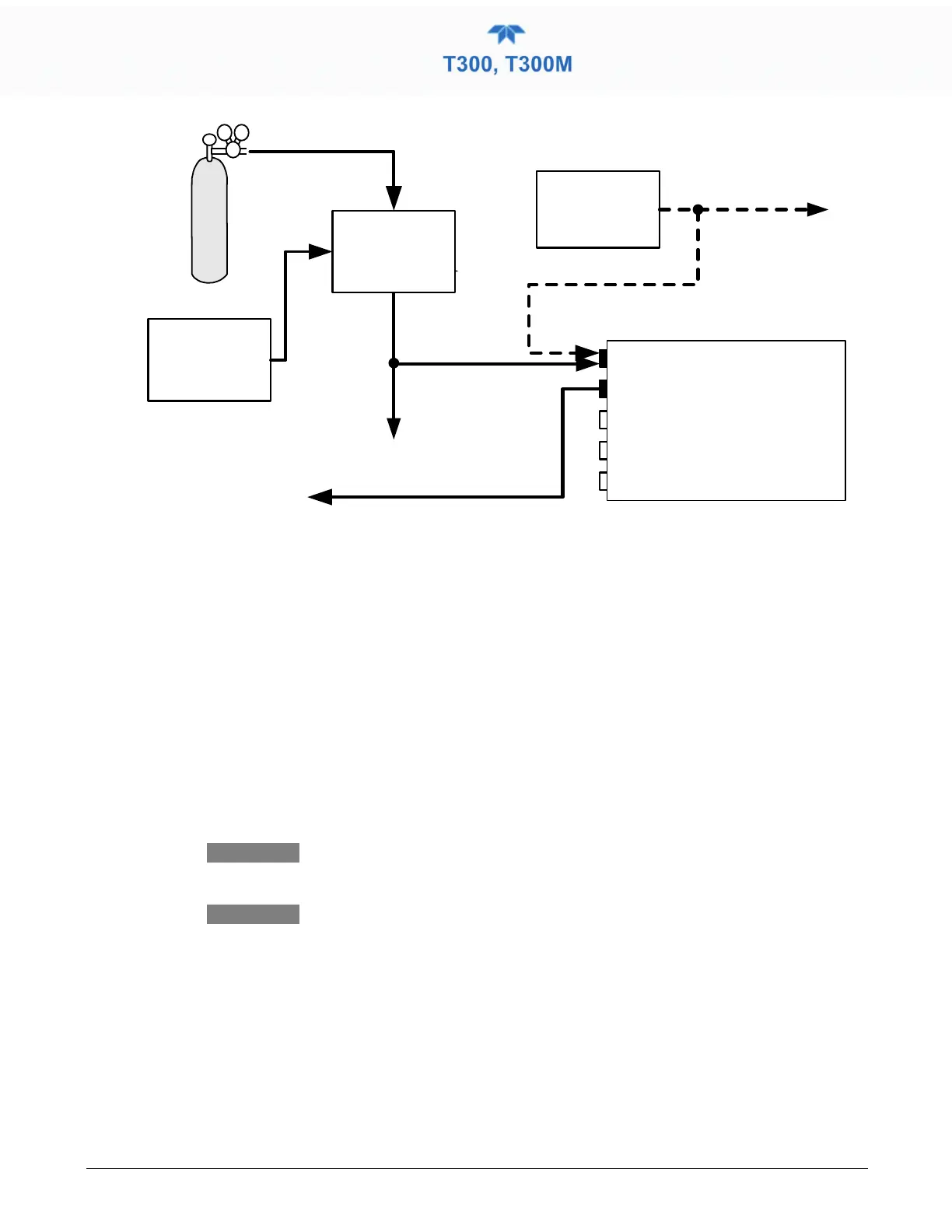

Source of

SAMPLE GAS

Removed during

calibration

VENT

MODEL 701

Zero Gas

Generator

Calibrated

CO Gas

at span gas

concentration

VENT

her e if input

is pressurized

SAMPLE

EXHAUST

Model 700 Gas

Dilution

Calibrator

Instrument

Chassis

Exhaust must be vented outside

of shelter or immediate area

sur rounding the instrument.

Figure 2-16. T300/T300M Pneumatic Connections – Basic Configuration Using Gas Dilution Calibrator

SAMPLE GAS SOURCE

Attach a sample inlet line to the SAMPLE inlet port. The sample input line should not

be more than 2 meters long.

• Maximum pressure of any gas at the sample inlet should not exceed 1.5 in-hg above

ambient pressure and ideally should equal ambient atmospheric pressure.

• In applications where the sample gas is received from a pressurized manifold, a vent must

be placed on the sample gas before it enters the analyzer.

CALIBRATION GAS SOURCES

The source of calibration gas is also attached to the SAMPLE inlet, but only when a

calibration operation is actually being performed.

Note T300M: EPA designation does not apply to this model.

Zero air and span gas inlets should supply their respective

gases in excess of the 800 cc3/min demand of the analyzer.

INPUT GAS VENTING

The span gas, zero air supply and sample gas line MUST be vented in order to ensure

that the gases input do not exceed the maximum inlet pressure of the analyzer as well as

to prevent back diffusion and pressure effects. These vents should be:

• At least 0.2m long;

• No more than 2m long and;

• Vented outside the shelter or immediate area surrounding the instrument.

Loading...

Loading...