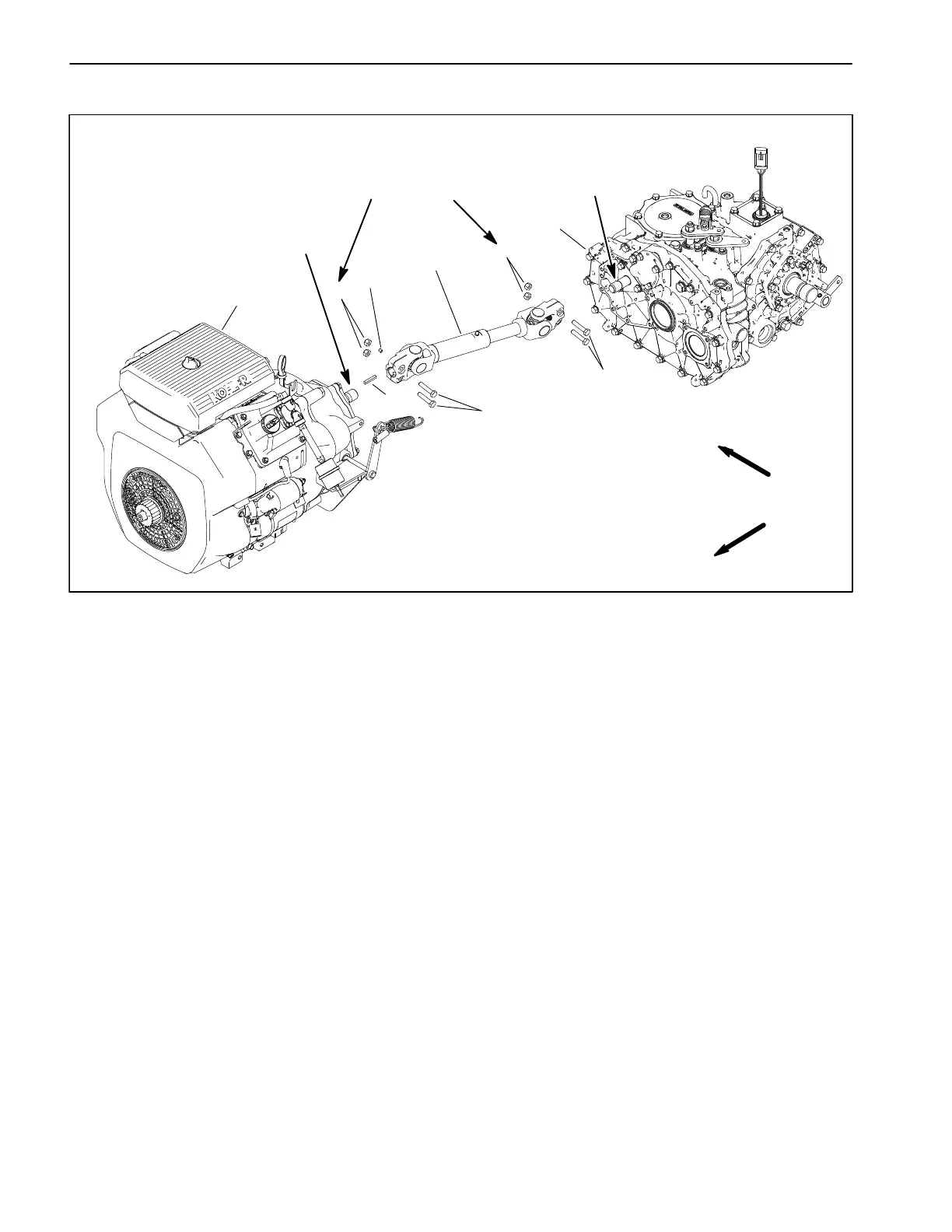

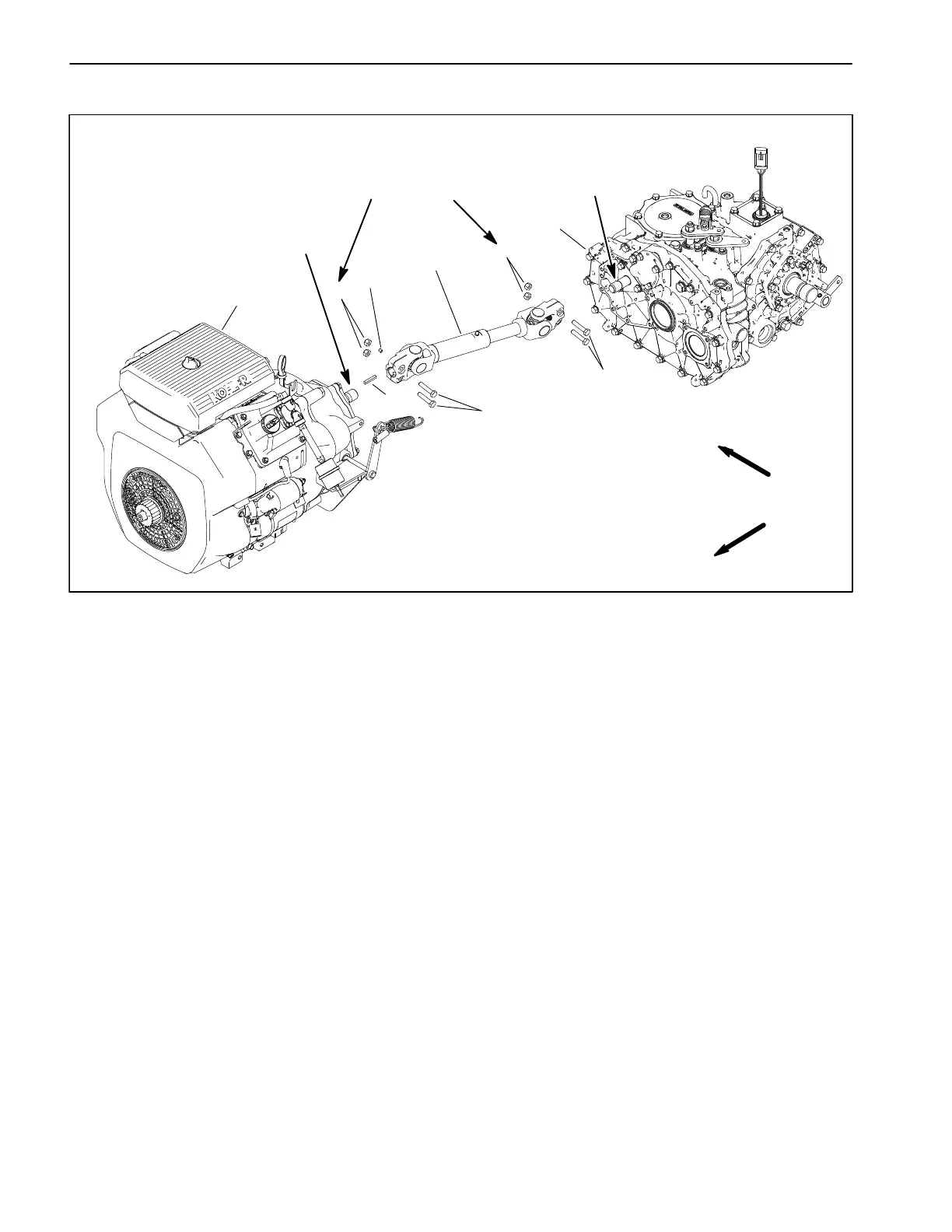

Multi Pro 1750Page 7 − 14Drive Train

Transaxle Driveshaft

1

2

3

3

4

4

5

7

6

1. Transaxle assembly

2. Engine

3. Cap screw (4 )

4. Lock nut (4)

5. Transaxle driveshaft

6. Set screw

7. Square key

Figure 8

FRONT

RIGHT

90 to 120 in−lb

(10.2 to 13.5 N−m)

Antiseize

Lubricant

Antiseize

Lubricant

Driveshaft Removal (Fig. 8)

1. Park machine on a level surface, stop spray pump,

stop engine and engage parking brake. Remove key

from ignition switch.

2. To remove driveshaft from transaxle, loosen and re-

move lock nuts and cap screws securing driveshaft to

splined input shaft of transaxle. Slide driveshaft yoke

from transaxle.

3. To remove driveshaft yoke from clutch bell housing,

loosen and remove lock nuts and cap screws securing

driveshaft to output shaft at bell housing. Remove set

screw (item 6) from yoke and then slide driveshaft yoke

from shaft. Locate and retrieve square key.

Driveshaft Installation (Fig. 8)

1. Apply antiseize lubricant to clutch bell housing out-

put shaft and transaxle input shaft

2. Position transaxle driveshaft to clutch bell housing

and transaxle shafts. Make sure that square key is

placed in shaft key slot.

3. Slide driveshaft yokes onto clutch bell housing and

transaxle shafts.

4. Install cap screws and lock nuts to secure driveshaft

yoke to output shaft at bell housing. Torque lock nuts

from 90 to 120 in−lb (10.2 to 13.5 N−m). Install and

tighten socket head screw (item 6) into yoke.

5. Install cap screws and lock nuts to secure driveshaft

yoke to splined transaxle input shaft. Torque lock nuts

from 90 to 120 in−lb (10.2 to 13.5 N−m).

Loading...

Loading...