Printing modes

T2-C User Guide 47

• UP/DN Adjustments - The Label Eye sensor has the ability to adjust the setup

incrementally. Simply momentarily tap the AUTOSET (UP) button, or LT/DK (DN) button to

adjust the sensor to a more stable and repeatable setting. This feature is used when the

AUTOSET does not provide the optimum setting initially.

Example: If the label backing material is inconsistent, or the label material has more

translucent areas coming into view, then the sensor may need to be adjusted slightly for

this rare occasion. Having the ability to fine tune the sensor for changing conditions

provides a solution that is easy to implement and simple to understand.

• Light/Dark - Push the LT/DK button to change output from Dark On to Light On. Output

LED turns on when label is in view, or output LED turns on when gap is in view.

1 Cut a piece from the liner only (peel off the label from top) and put the piece of liner under

the dot at the middle of the LABEL • EYE™ text on the sensor, where the small dot indicates

the exact position of the sensor beam.

2 Keeping the piece of liner under the sensor beam, press and hold the AUTOSET button on

the sensor until only the green AUTOSET LED is lit constantly (the red output and the green

autoset LEDs will start flashing first and then the red LED goes off and the green LED stays

lit if calibration is successful).

3 Check detection by moving a label (not gap) into the sensor beam. If sensor is properly

calibrated, then the red output indicator LED will go on indicating that the sensor can

differentiate between gap and label. When only a label gap (liner) is under the sensor, then

only the green autoset LED is lit.

4 Repeat the calibration in case you do not see the same result as described in point 3 above.

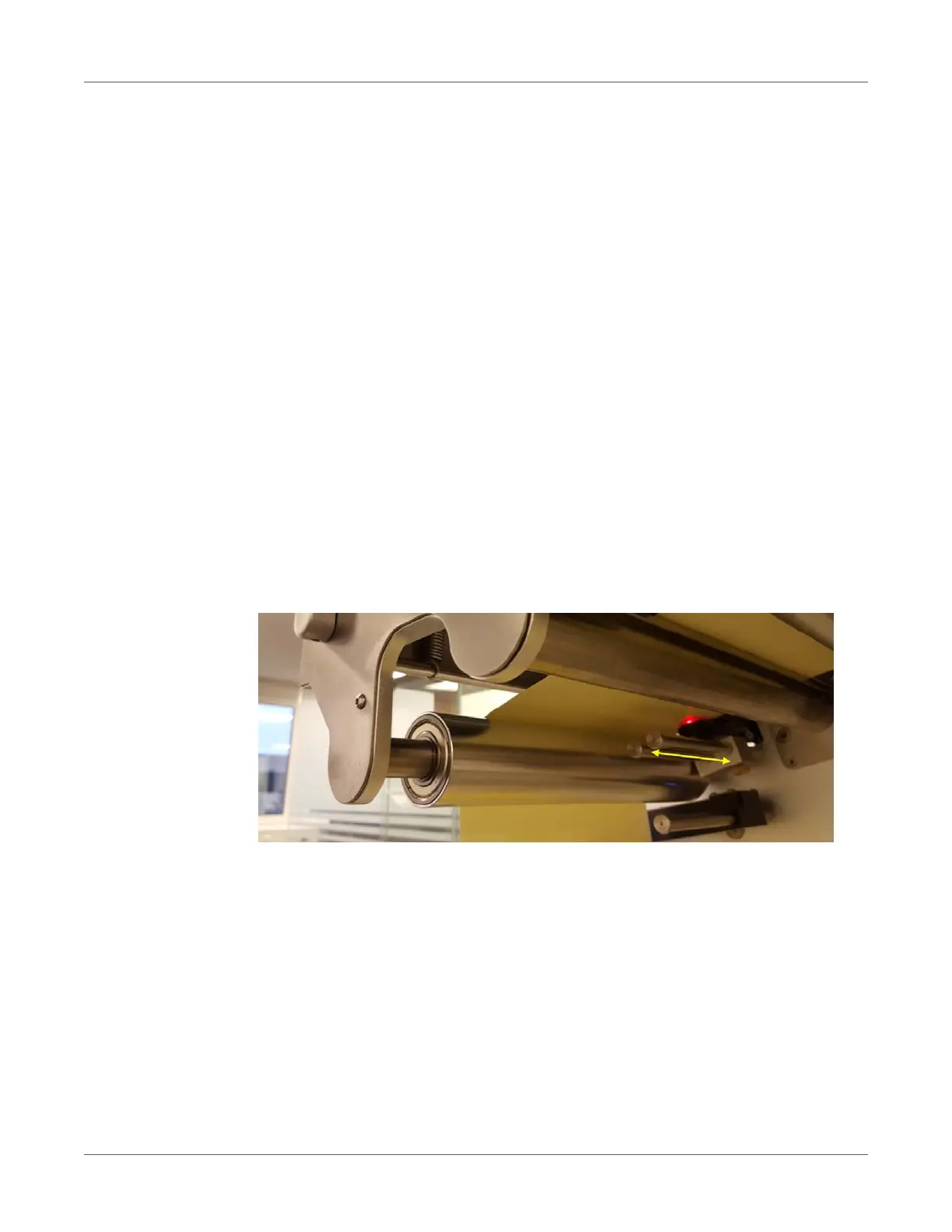

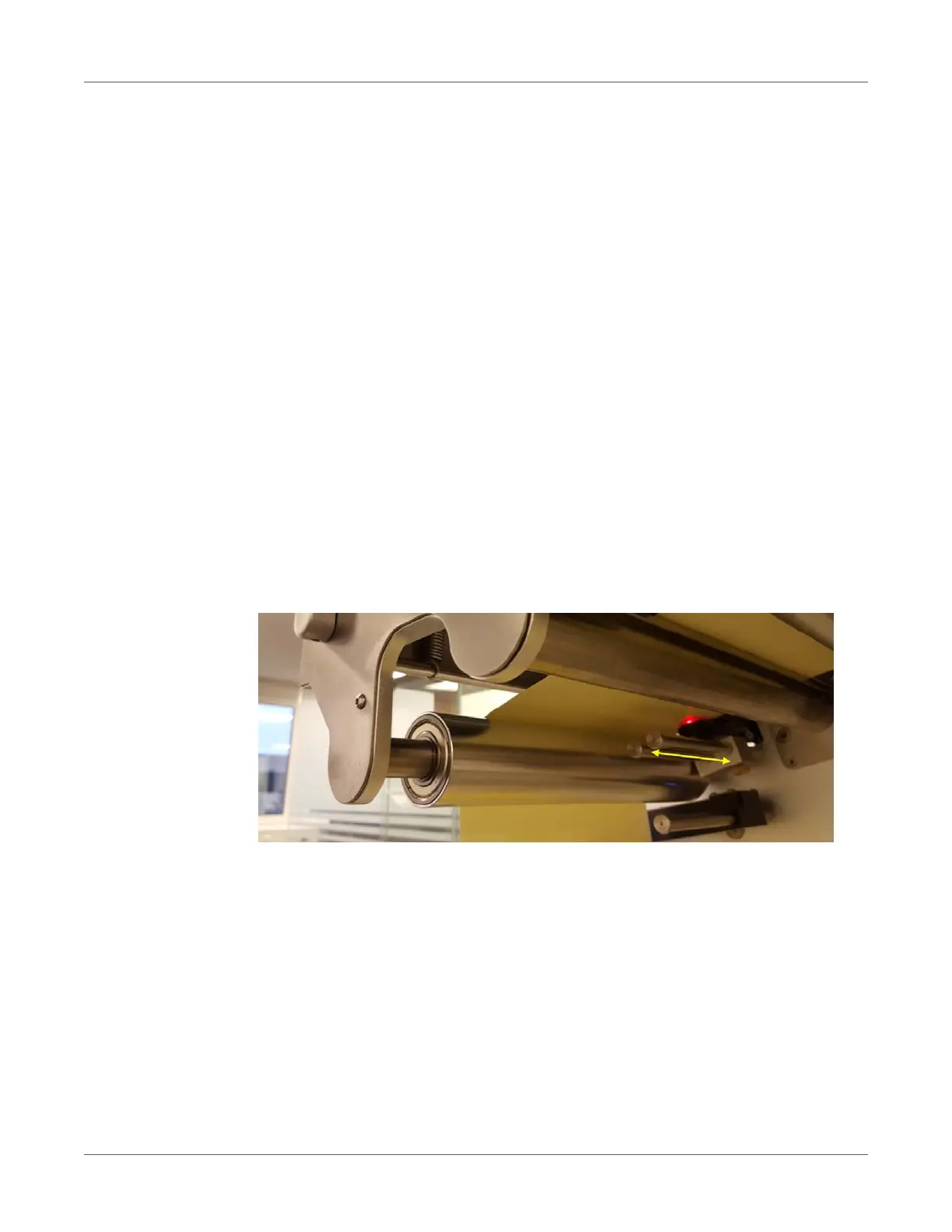

Label eye sensor for detecting label gaps and black marks. Sensor can be moved manually

along the 2 rods (indicated with yellow arrow on picture above).

Because of inter-page actions the printed labels require:

• Minimum 2.2 mm gap at 6 IPS mode

• Minimum 3 mm gap at 12 IPS mode

• Maximum gap size is 65 mm

Important: Setting the label gap outside the minimum and maximum range can result in

label skipping or high label gaps.

Loading...

Loading...