4.3 Controller I/O

Emergency Stop Safeguard Stop

Robot stops moving Yes Yes

Program execution Stops Pauses

Robot power Off On

Reset Manual Automatic or manual

Frequency of use Infrequent Every cycle to infrequent

Requires re-initialization Brake release only No

Stop category (IEC 60204) 1 2

Performance level of

monitoring function (ISO 13849-1) PLd PLd

It is possible to use the configurable I/O to set up additional safety I/O functionality,

e.g. emergency stop output. Configuring a set of configurable I/O for safety functions

are done through the GUI, see part II.

Some examples of how to use safety I/O are shown in the following subsections.

DANGER:

1. Never connect safety signals to a PLC which is not a safety

PLC with the correct safety level. Failure to follow this warn-

ing could result in serious injury or death as one of safety stop

functions could be overridden. It is important to keep safety in-

terface signals separated from the normal I/O interface signals.

2. All safety-related I/O are constructed redundantly (Two inde-

pendent channels). Keep the two channels separate so that a

single fault cannot lead to loss of the safety function.

3. Safety functions must be verified before putting the robot into

operation. Safety functions must be tested regularly.

4. The robot installation shall conform to these specifications. Fail-

ure to do so could result in serious injury or death as the safety

stop function could be overridden.

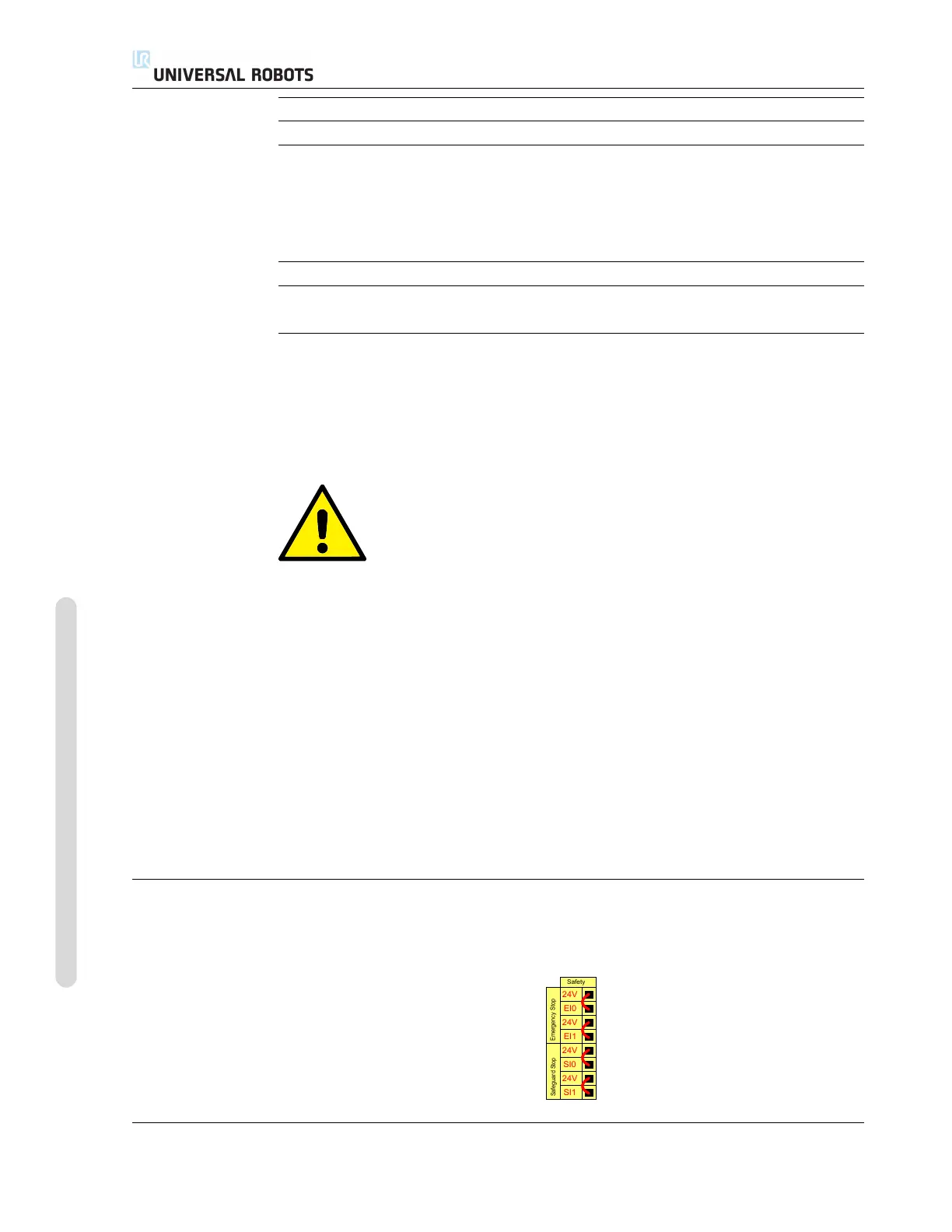

4.3.2.1 Default safety configuration

The robot is shipped with a default configuration which enables operation without

any additional safety equipment, see illustration below.

24V

EI1

24V

SI0

24V

SI1

24V

EI0

Safety

Safeguard Stop

Emergency Stop

UR5/CB3 I-24 Version 3.1 (rev. 17782)

Copyright © 2009-2015 by Universal Robots A/S. All rights reserved.

Loading...

Loading...