12.13 Conveyor Tracking Setup

12.13 Conveyor Tracking Setup

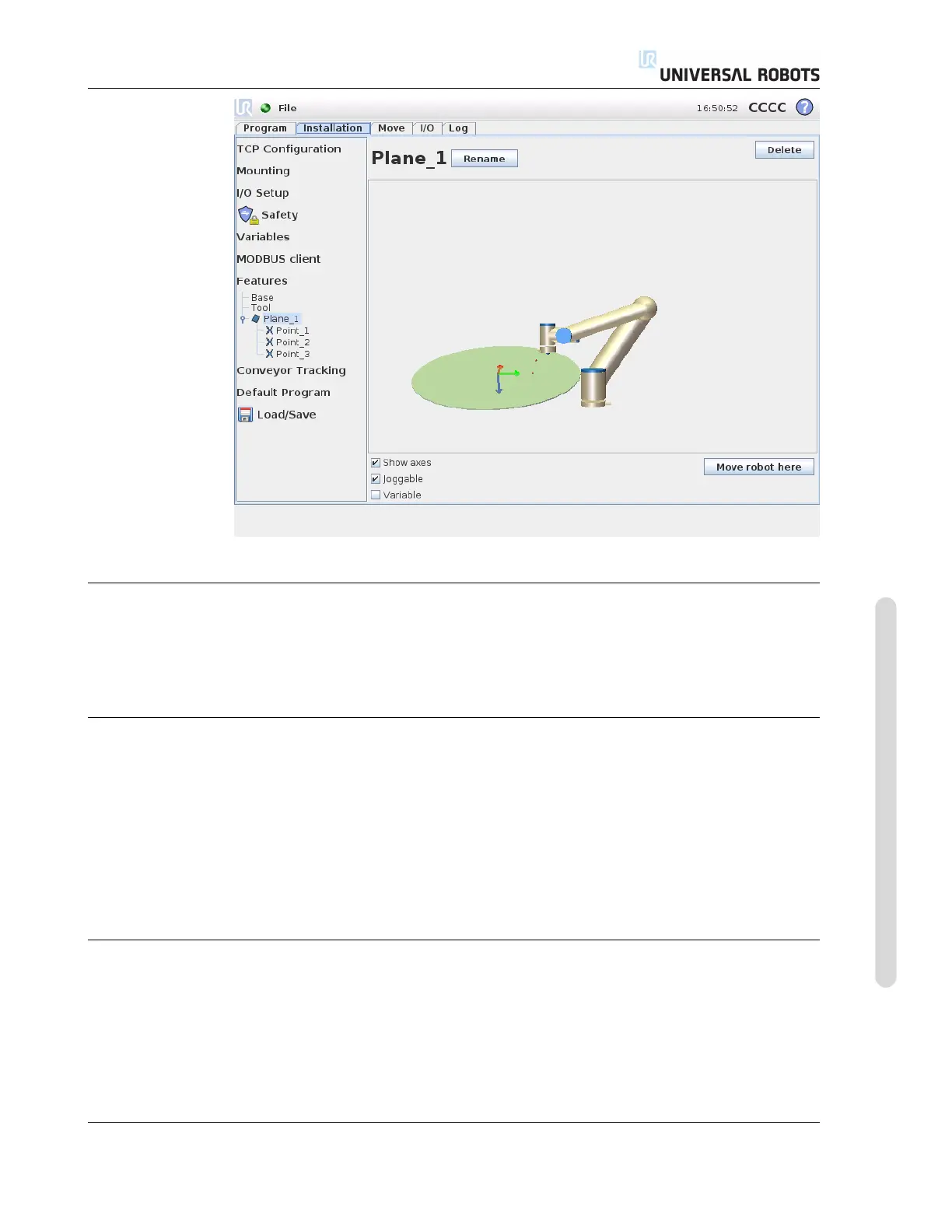

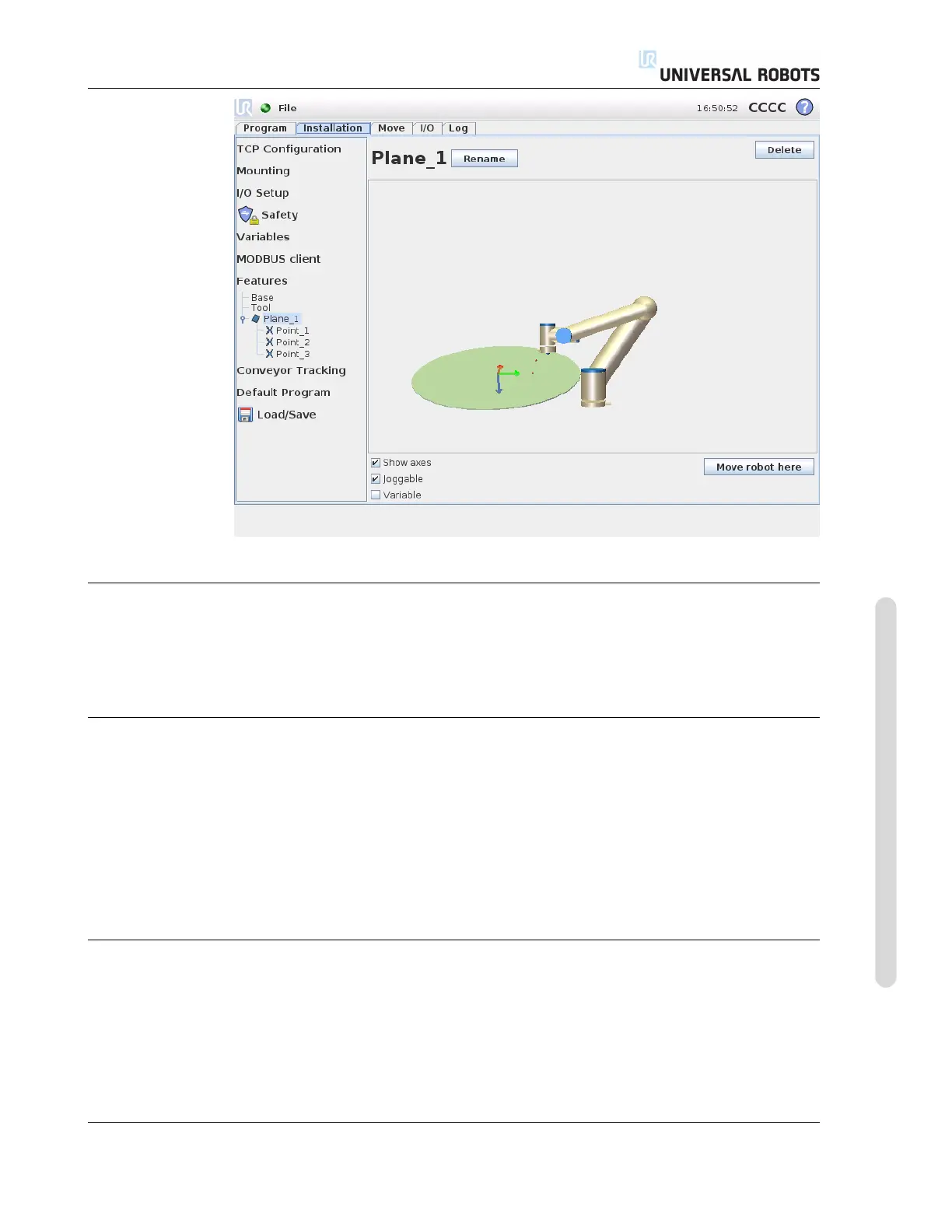

When using a conveyor, the robot can be configured to track the movement of the

conveyor. The Conveyor Tracking Setup provides options for configuring the robot to

work with absolute and incremental encoders, and linear and circular conveyors.

Conveyor Parameters

Incremental encoders can be connected to digital inputs 0 to 3. Using a Quadrature

encoder (requiring two inputs), the robot is able to determine the speed and direction

of the conveyor. If the direction of the coneyor is constant, a single input can be used,

counting on Rising, Falling, or Rise and Fall edges to determine the speed of

the conveyor.

Absolute encoders can be used when connected through a MODBUS signal. This

requires that a digital MODBUS input register is preconfigured in the 12.11.

Linear conveyors

When a linear conveyor is selected, a line feature must be configured to determine the

direction of the conveyor. The line feature should be parallel to the direction of the

conveyor, and there should be a large distance between the two points defining the

line feature. It is recommended to configure the line feature by by placing the tool

firmly against the side of the conveyor when teaching the two points.

Version 3.1 (rev. 17782)

Copyright © 2009-2015 by Universal Robots A/S. All rights reserved.

II-37 CB3

Loading...

Loading...