5.3 Controller I/O

DANGER:

1. Never connect safety signals to a PLC which is not a safety

PLC with the correct safety level. Failure to follow this warn-

ing could result in serious injury or death as one of safety stop

functions could be overridden. It is important to keep safety

interface signals separated from the normal I/O interface sig-

nals.

2. All safety-related I/O are constructed redundantly (Two in-

dependent channels). Keep the two channels separate so that

a single fault cannot lead to loss of the safety function.

3. Safety functions must be verified before putting the robot into

operation. Safety functions must be tested regularly.

4. The robot installation shall conform to these specifications.

Failure to do so could result in serious injury or death as the

safety stop function could be overridden.

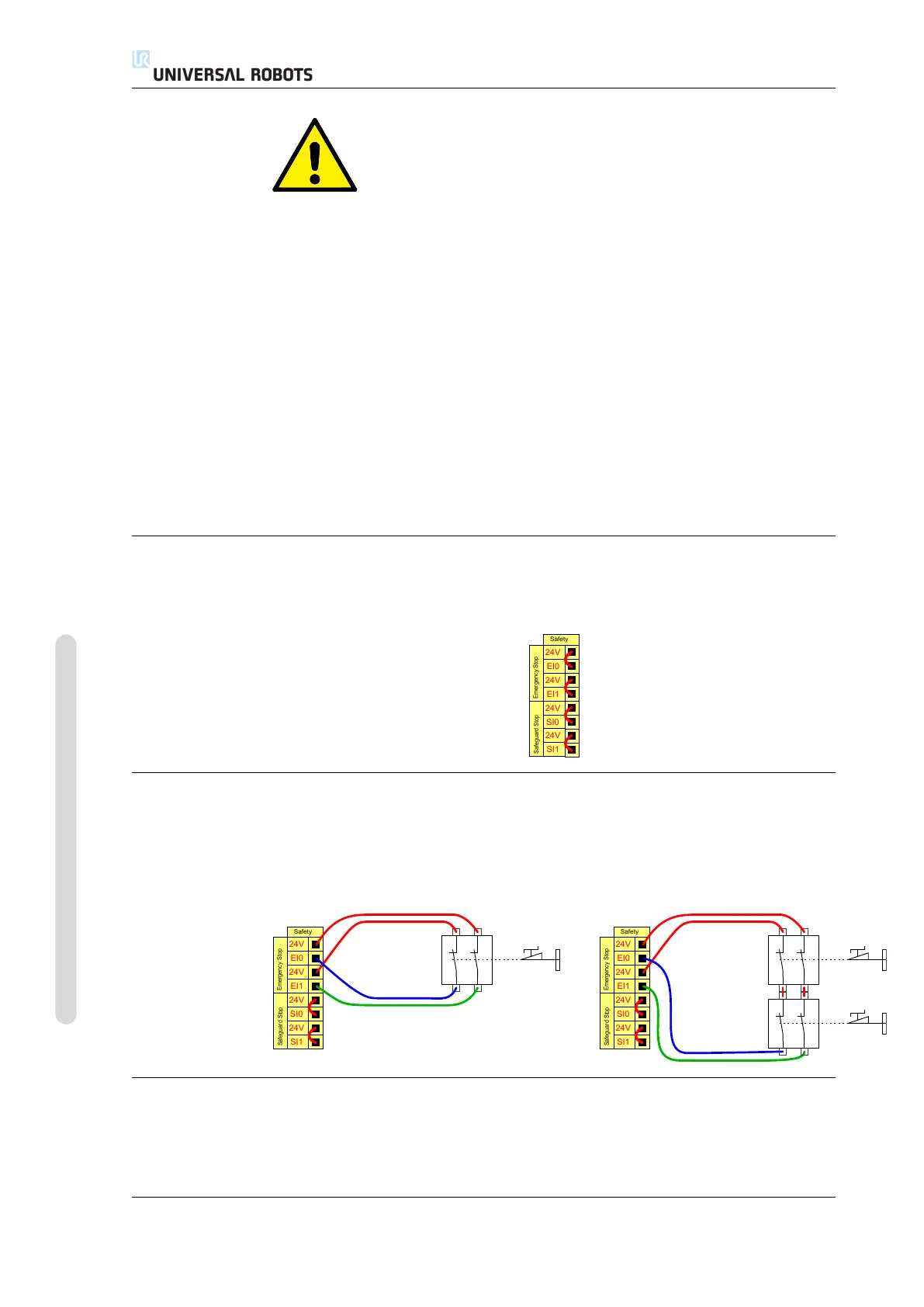

5.3.2.1 Default safety configuration

The robot is shipped with a default configuration which enables operation without

any additional safety equipment, see illustration below.

24V

EI1

24V

SI0

24V

SI1

24V

EI0

Safety

Safeguard Stop

Emergency Stop

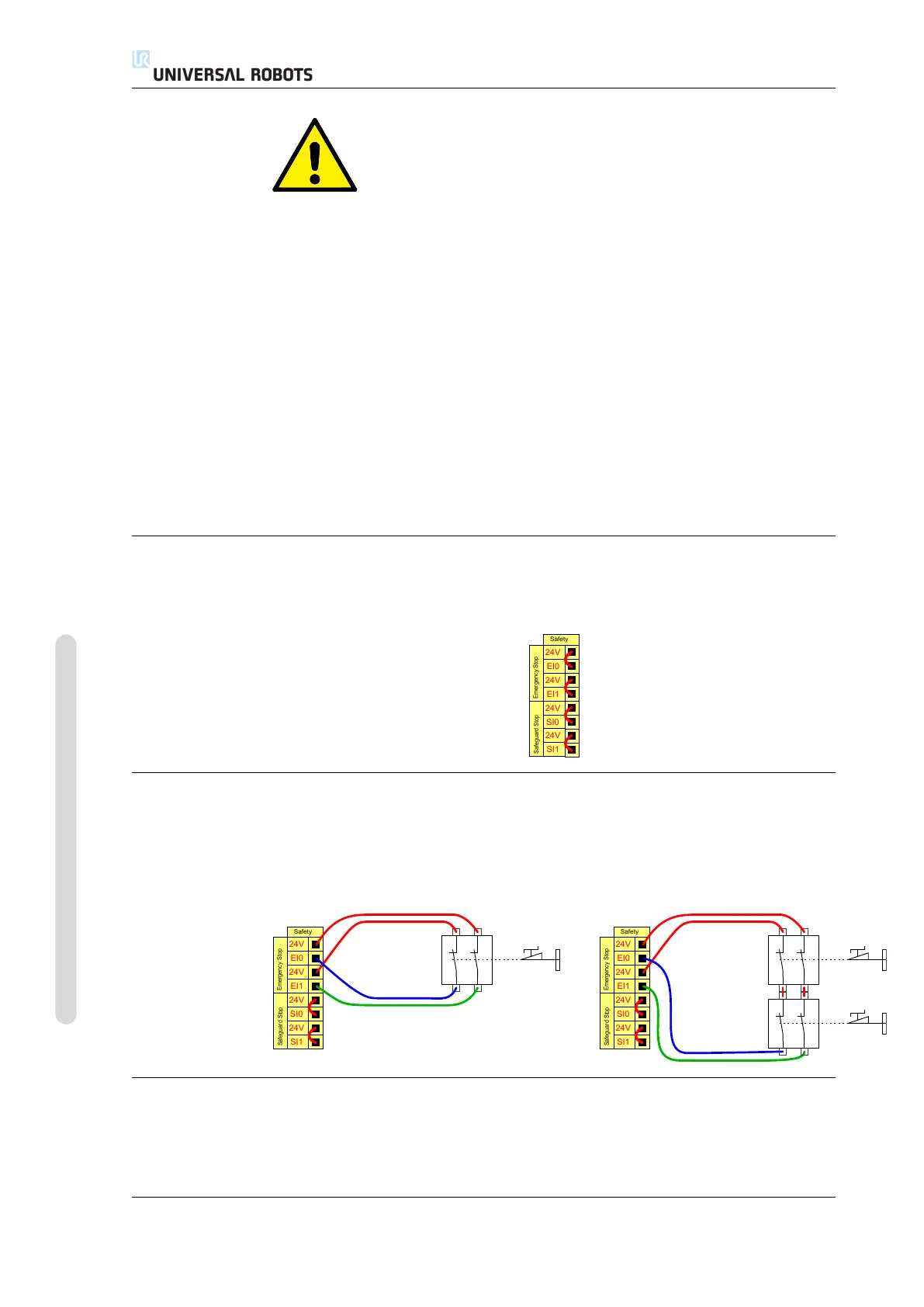

5.3.2.2 Connecting emergency stop buttons

In most applications it is required to use one or more extra emergency stop but-

tons. The illustration below shows how one or more emergency stop buttons can

be connected.

24V

EI1

24V

SI0

24V

SI1

24V

EI0

Safety

Safeguard Stop

Emergency Stop

24V

EI1

24V

SI0

24V

SI1

24V

EI0

Safety

Safeguard Stop

Emergency Stop

5.3.2.3 Sharing emergency stop with other machines

It is often desired to set up a common emergency stop circuit when the robot is

used together with other machines. By doing so, the operator does not need to

think about which emergency stop buttons to use.

UR5/CB3 I-32 Version 3.4.5

Copyright © 2009–2017 by Universal Robots A/S. All rights reserved.

Loading...

Loading...