10.6 Safety Modes

2. Revert back to the previously applied safety configuration. This will disregard

all changes and allow you to continue to the desired selected destination.

10.4 Tolerances

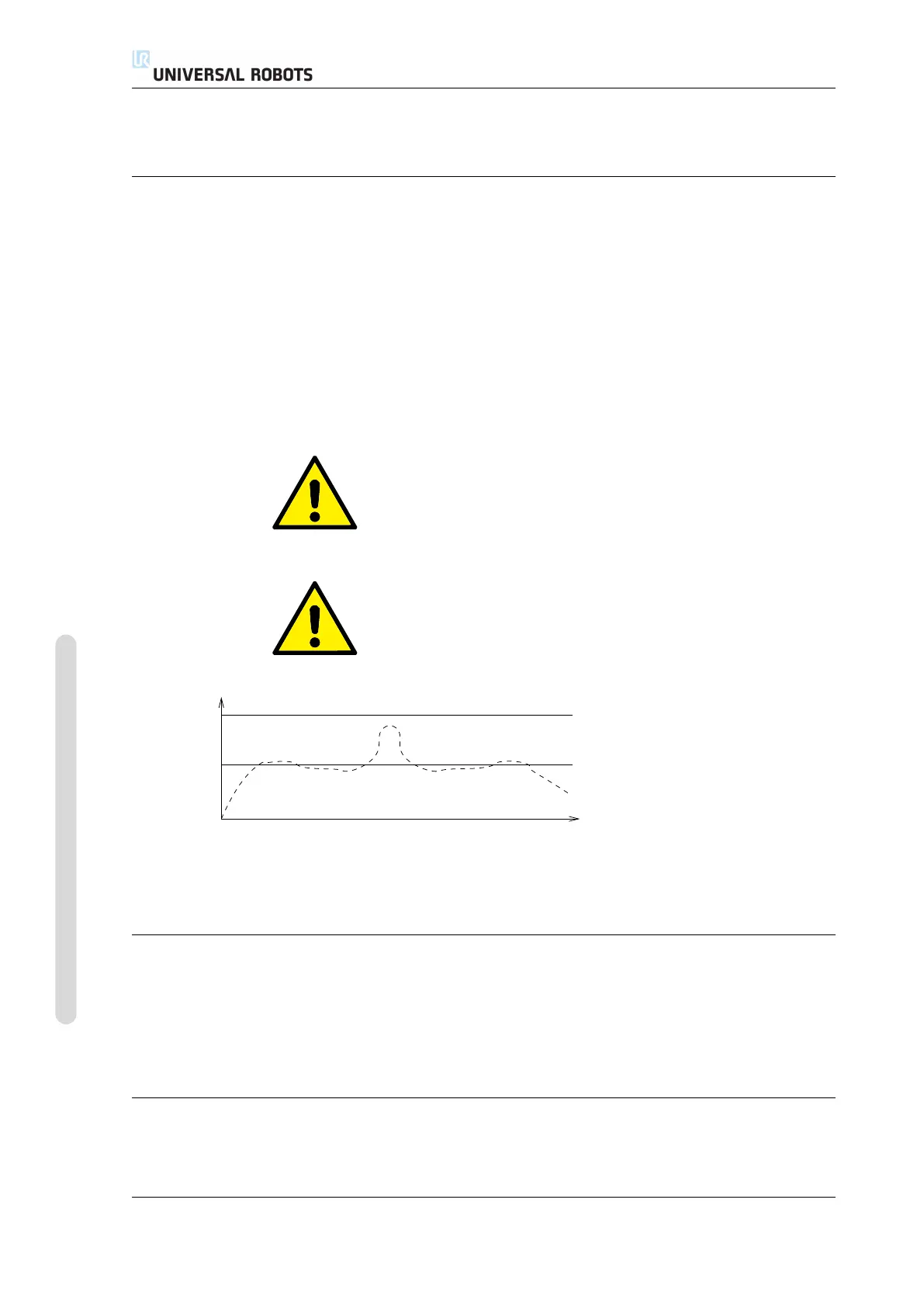

The Robot Arm uses built-in tolerances that prevent safety violations. A safety tol-

erance is the difference between a safety limit and a maximum operational value.

For example, the general speed tolerance is −150mm/s. This means that if the user

configures a 250mm/s speed limit, then the maximum operational speed will be

250 − 150 = 100mm/s. Safety tolerances prevent safety violations while allowing

for fluctuations in program behavior. For example, when handling a heavy pay-

load, there may be situations where the Robot Arm needs to briefly operate above

the normal maximum operational speed to follow a programmed trajectory. An

example of such a situation is shown in figure 10.1.

WARNING:

A risk assessment is always required using the limit values with-

out tolerances.

WARNING:

Tolerances are specific to the version of the software. Updating the

software may change the tolerances. Consult the release notes for

changes between versions.

Time

Speed

Actual speed

Safety speed limit

Maximum operational speed

Figure 10.1: Safety tolerance example.

10.5 Safety Checksum

The text in the top right corner of the screen gives a shorthand representation of

the safety configuration currently used by the robot. When the text changes, this

indicates that the current safety configuration has changed as well. Clicking on the

checksum displays the details about the currently active safety configuration.

10.6 Safety Modes

Under normal conditions (i.e. when no protective stop is in effect), the safety system

operates in one of the following safety modes, each with an associated set of safety

CB3 II-6 Version 3.4.5

Copyright © 2009–2017 by Universal Robots A/S. All rights reserved.

Loading...

Loading...