5-36

E

POWR

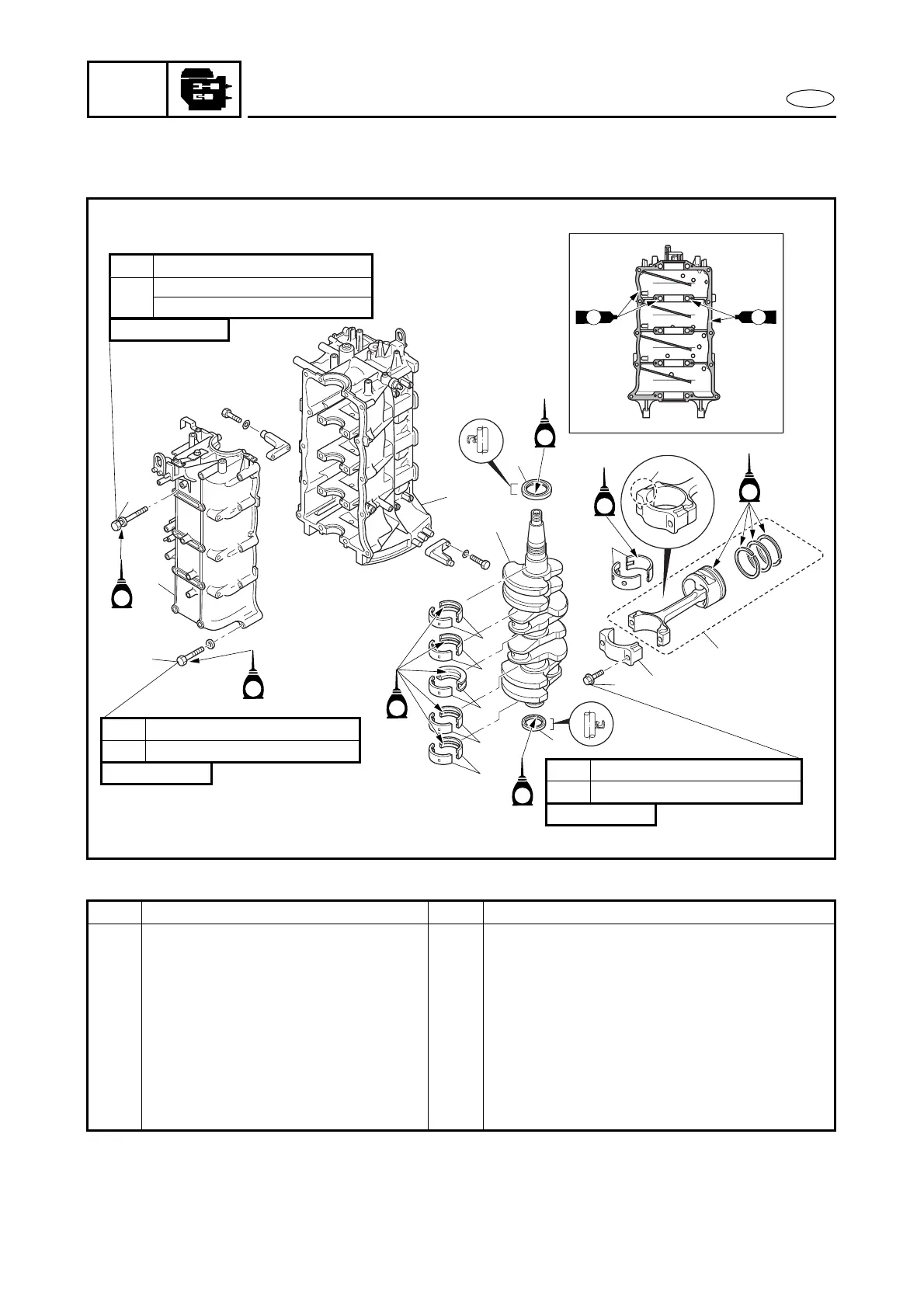

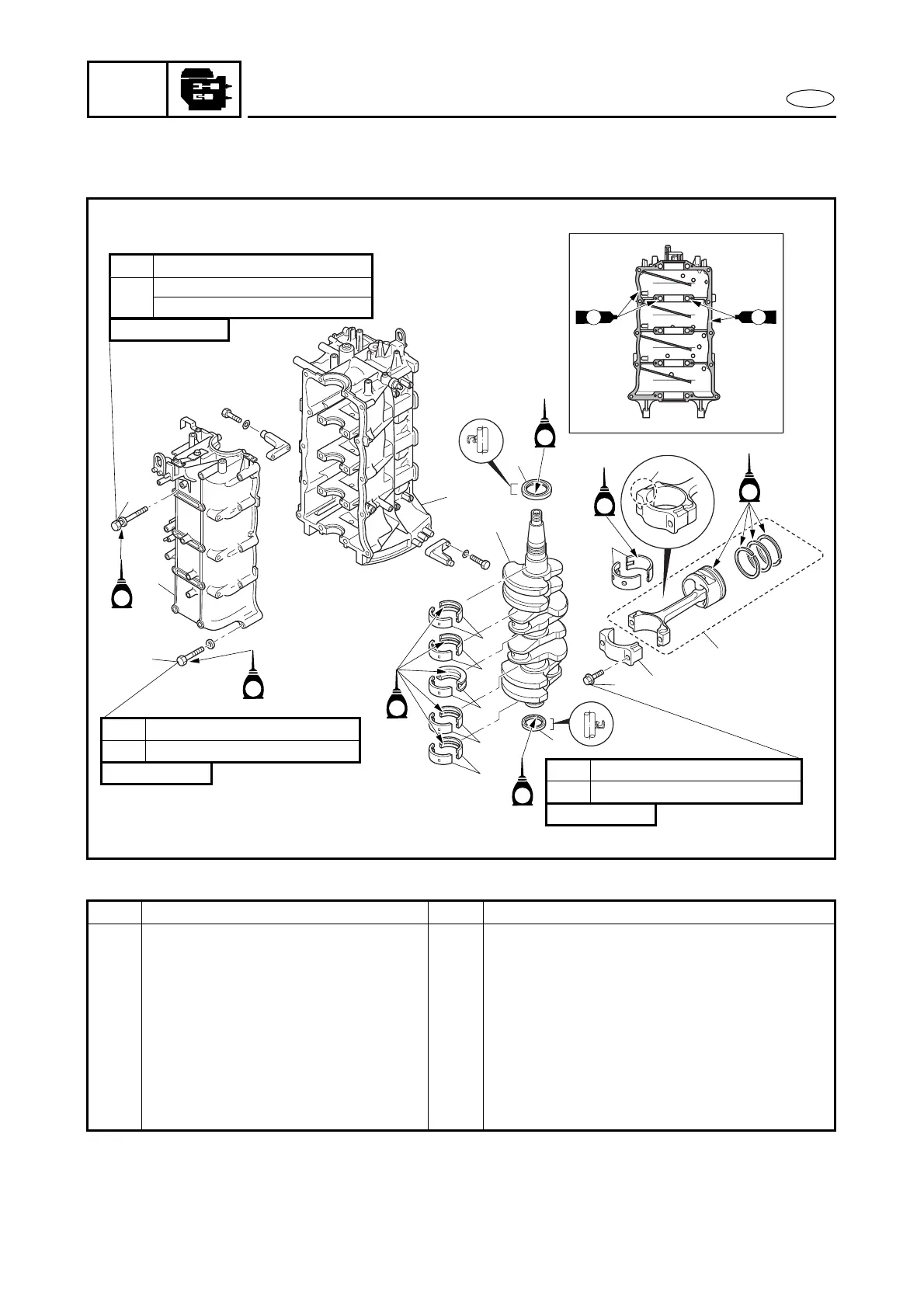

CRANKSHAFT AND PISTON/

CONNECTING ROD ASSY.

EXPLODED DIAGRAM

19 Nm (1.9 m

•

kg, 14 ft

•

Ib)1st

60°

2nd

10 × 135 mm

14 Nm (1.4 m

•

kg, 10 ft

•

Ib)1st

28 Nm (2.8 m

•

kg, 20 ft

•

Ib)2nd

8 × 55 mm

8 Nm (0.8 m

•

kg, 5.8 ft

•

Ib)1st

90°2nd

8 × 38 mm

E

E

E

E

E

E

2

3

1

7

11

9

4

8

10

12

6

5

GM

GM

GM

GM

7

7

7

7

E

a

50 Nm (5.0 m

•

kg, 36 ft

•

Ib)*

Step Procedure/Part name Q’ty Service points

6 Crankshaft 1

7 Main bearing 5 Install in the original position.

8 Big end bearing 4 Install in the original position.

9 Piston/connecting rod assy. 4 Face the large, flat side a towards the

flywheel.

10 Oil seal 1 Install the oil seals before installing the

crankcase.

11 Oil seal 1

12 Cylinder block 1

Reverse the removal steps for installation.

Loading...

Loading...