5-37

POWR

E

CRANKSHAFT AND PISTON/

CONNECTING ROD ASSY.

SERVICE POINTS

Cylinder block inspection

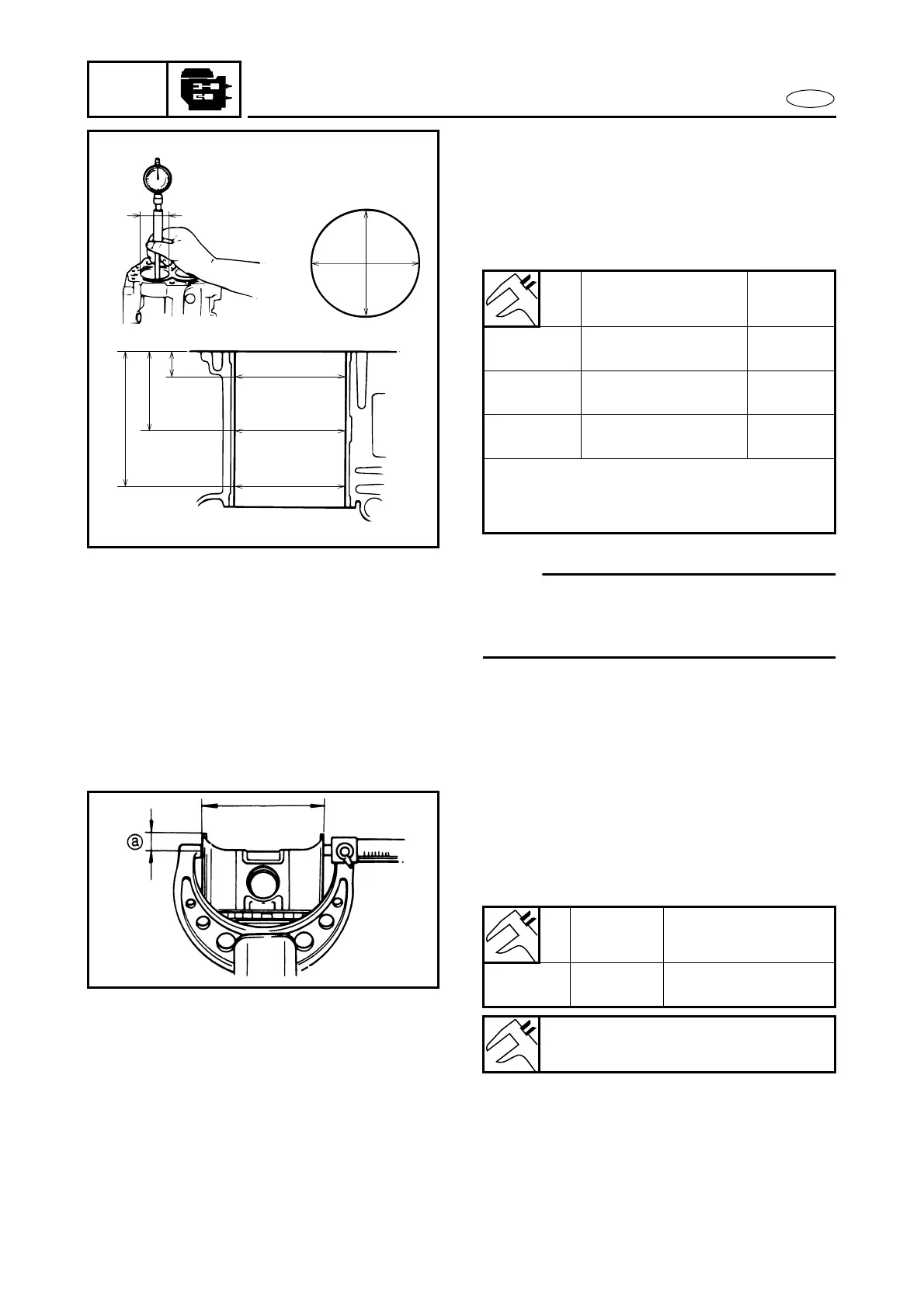

1. Measure:

● Cylinder bore

Out of specification → Rebore the cyl-

inder or replace the cylinder block.

NOTE:

Measure the cylinder bore in parallel and at

a right angle to the crankshaft. Then, aver-

age the measurements.

Standard

Wear

limit

Cylinder

bore “D”

79.000 ~ 79.020 mm

(3.110 ~ 3.111 in)

—

Taper

limit “T”

—

0.08 mm

(0.003 in)

Out of

round limit

—

0.08 mm

(0.003 in)

D = Maximum Dia. (D

1 ~ D6)

T = (maximum D

1 or D2) – (minimum D5

or D6)

D

20mm(0.8in)

D1 and D2

D3 and D4

D5 and D6

70mm(2.8in)

120mm(4.7in)

D2

D1

Piston inspection

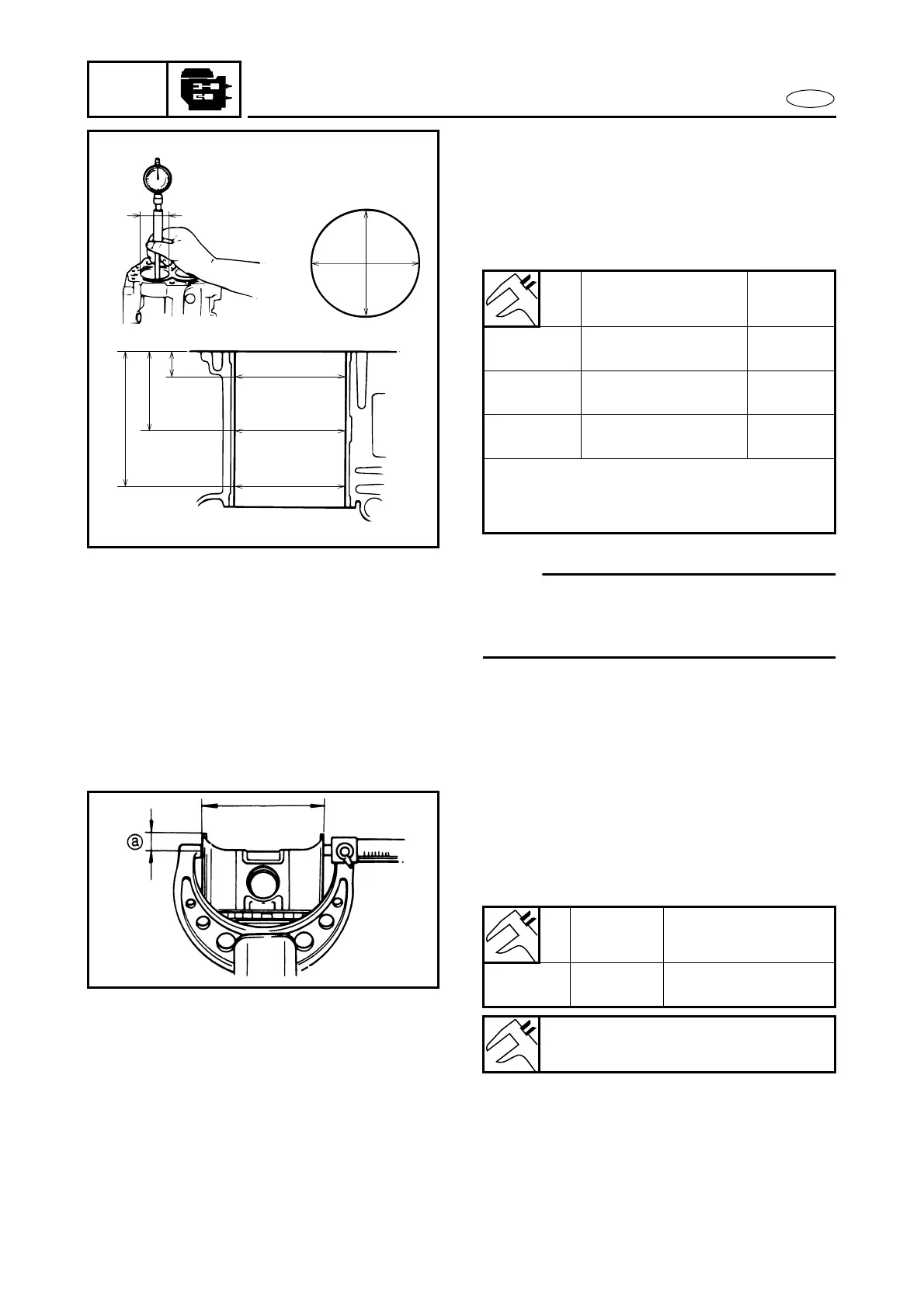

1. Measure:

● Piston diameter

Out of specification → Replace the

piston.

Distance

a

Piston diameter

Standard

13 mm

(0.51 in)

78.928 ~ 78.949 mm

(3.1074 ~ 3.1082 in)

Oversize piston diameter:

Oversize 1: + 0.25 mm (0.001 in)

Loading...

Loading...