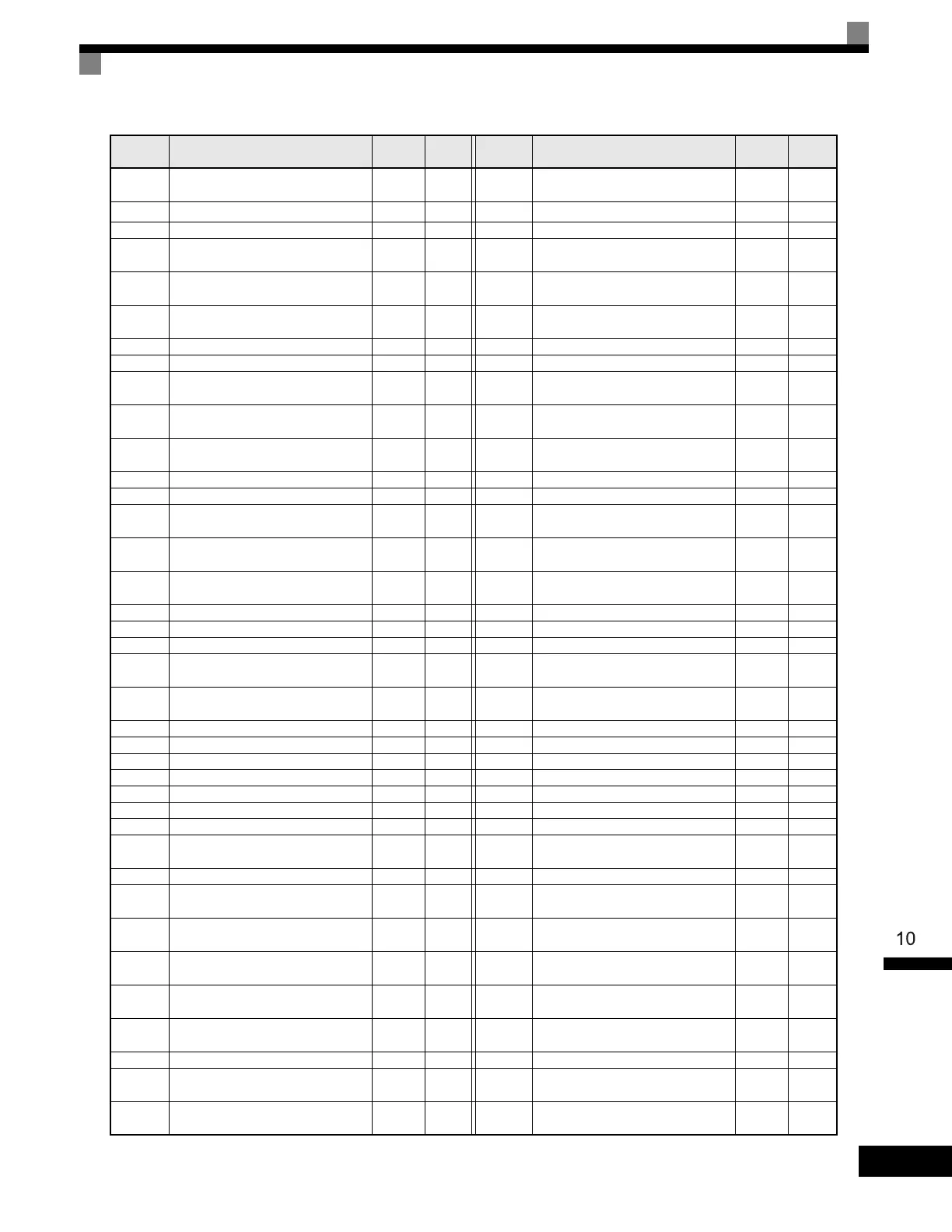

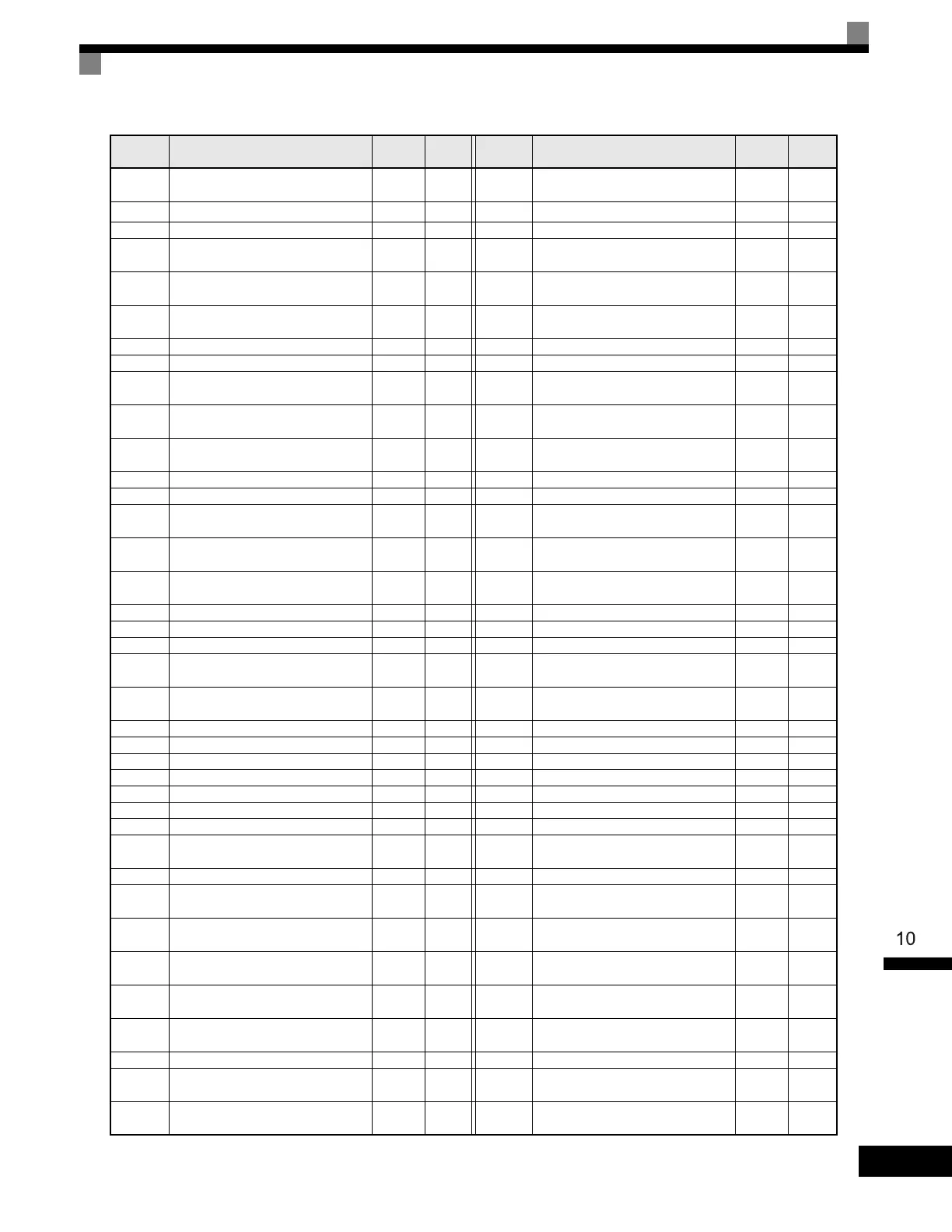

User Parameters

10-23

H3-05

Multi-function analog input (termi-

nal A3)

2 L2-04 Voltage recovery time 0.3

H3-06 Gain (terminal A3) 100.0 L2-05 Undervoltage detection level

190

*7

H3-07 Bias (terminal A3) 0.0 L2-06 KEB deceleration time 0.0

H3-08

Multi-function analog input termi-

nal A2 function selection

2 L2-07 Momentary recovery time

0

*11

H3-09

Multi-function analog input termi-

nal A2 signal level selection

0 L2-08

Frequency reduction gain at KEB

start

100

H3-10 Gain (terminal A2) 100.0 L3-01

Stall prevention selection during

accel

1

H3-11 Bias (terminal A2) 0.0 L3-02 Stall prevention level during accel 150

H3-12 Analog input filter time constant 0.03 L3-03 Stall prevention limit during accel 50

H4-01 Monitor selection (terminal FM) 2 L3-04

Stall prevention selection during

decel

1

H4-02 Gain (terminal FM) 1.00 L3-05

Stall prevention selection during

running

1

H4-03 Bias (terminal FM) 0.0 L3-06

Stall prevention level during run-

ning

160

H4-04 Monitor selection (terminal AM) 3 L4-01 Speed agreement detection level 0.0

H4-05 Gain (terminal AM) 0.50 L4-02 Speed agreement detection width 2.0

H4-06 Bias (terminal AM) 0.0 L4-03

Speed agreement detection level

(+/-)

0.0

H4-07

Analog output 1 signal level selec-

tion

0 L4-04

Speed agreement detection width

(+/-)

2.0

H4-08

Analog output 2 signal level selec-

tion

0 L4-05

Operation when frequency refer-

ence is missing

0

H5-01 Station address 1F L5-01 Number of auto restart attempts 0

H5-02 Communication speed selection 3 L5-02 Auto restart operation selection 0

H5-03 Communication parity selection 0 L6-01 Torque detection selection 1 0

H5-04

Stopping method after communi-

cation error

3 L6-02 Torque detection level 1 150

H5-05

Communication error detection

selection

1 L6-03 Torque detection time 1 0.1

H5-06 Send wait time 5 L6-04 Torque detection selection 2 0

H5-07 RTS control ON/OFF 1 L6-05 Torque detection level 2 150

H6-01 Pulse train input function selection 0 L6-06 Torque detection time 2 0.1

H6-02 Pulse train input scaling 1440 L7-01 Forward drive torque limit 200

H6-03 Pulse train input gain 100.0 L7-02 Reverse drive torque limit 200

H6-04 Pulse train input bias 0.0 L7-03 Forward regenerative torque limit 200

H6-05 Pulse train input filter time 0.10 L7-04 Reverse regenerative torque limit 200

H6-06 Pulse train monitor selection 2 L8-01

Protect selection for internal DB

resistor (Type ERF)

0

H6-07 Pulse train monitor scaling 1440 L8-02 Overheat pre-alarm level 95

L1-01 Motor protection selection 1 L8-03

Operation selection after overheat

pre-alarm

3

L1-02 Motor protection time constant 1.0 L8-05

Input open-phase protection selec-

tion

0

L1-03

Alarm operation selection during

motor overheating

3 L8-07

Output open-phase protection

selection

0

L1-04

Motor overheating operation selec-

tion

1 L8-09 Ground protection selection 1

L1-05

Motor temperature input filter time

constant

0.20 L8-10 Cooling fan control selection 0

L2-01 Momentary power loss detection 0 L8-11 Cooling fan control delay time 60

L2-02

Momentary power loss ridethru

time

0.1

*6

L8-12 Ambient temperature 45

L2-03 Min. baseblock time 0.5 L8-15

OL2 characteristics selection at

low speeds

1

Table 10.7 User Parameters (Continued)

No. Name

Factory

Setting

Setting No. Name

Factory

Setting

Setting

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...