QA (Quality Assurance)

191

Operation Manual

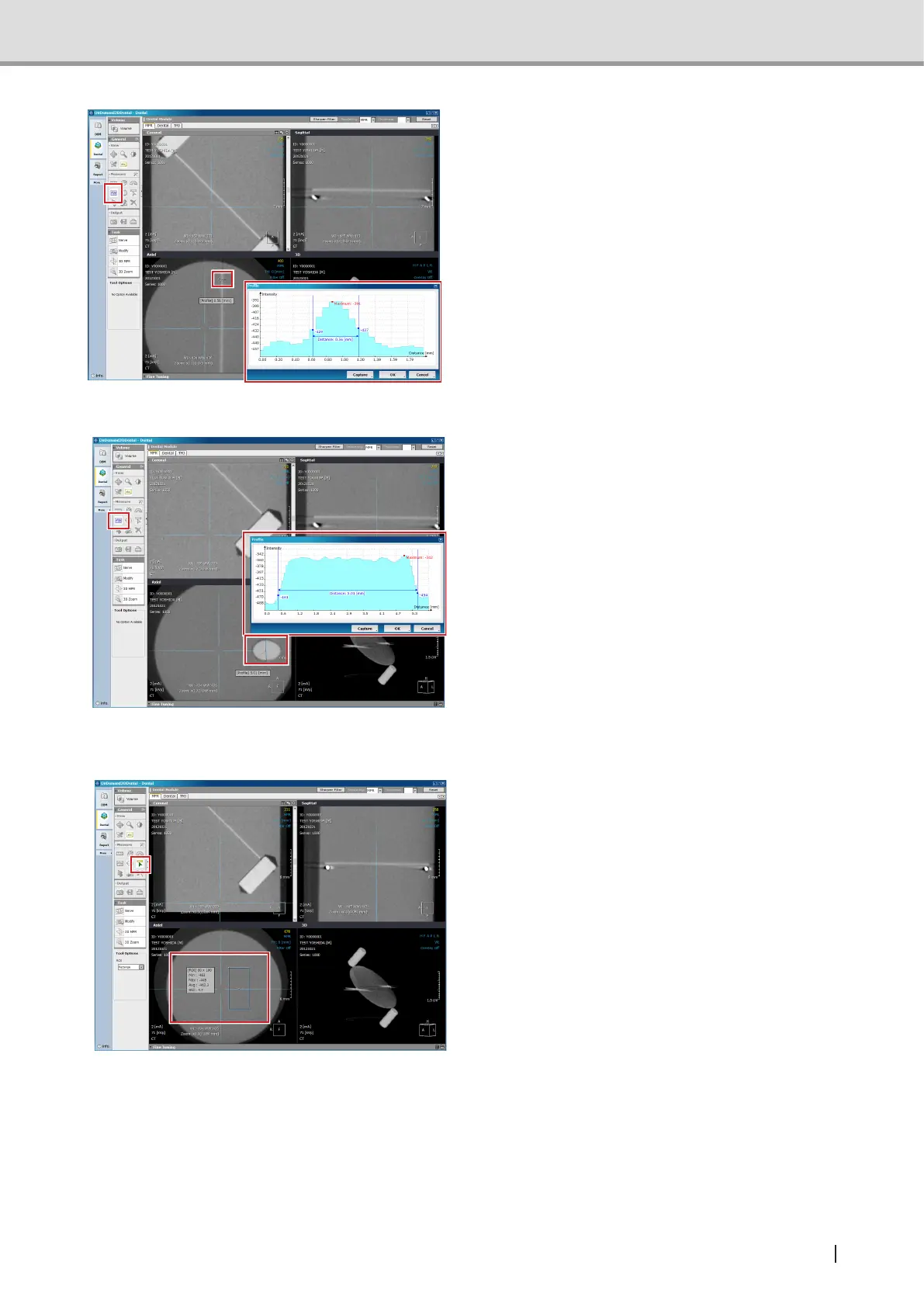

4 Measure aluminum disk thickness

from Axial image. However, measure it

without adjusting the crossbar tilt.

Where to measure is described in the

gurebelow.Measuringpointisabovethe

lowerTeonpinandbelowthealuminum

diskcenter.Usetheprolefunctiontoset

theprolesoitwillbeperpendiculartothe

Aluminum disk shown in the Axial image.

Measure the width of the graph when the

height of the graph is approximately 50%.

Acceptance value 0.7 mm or less

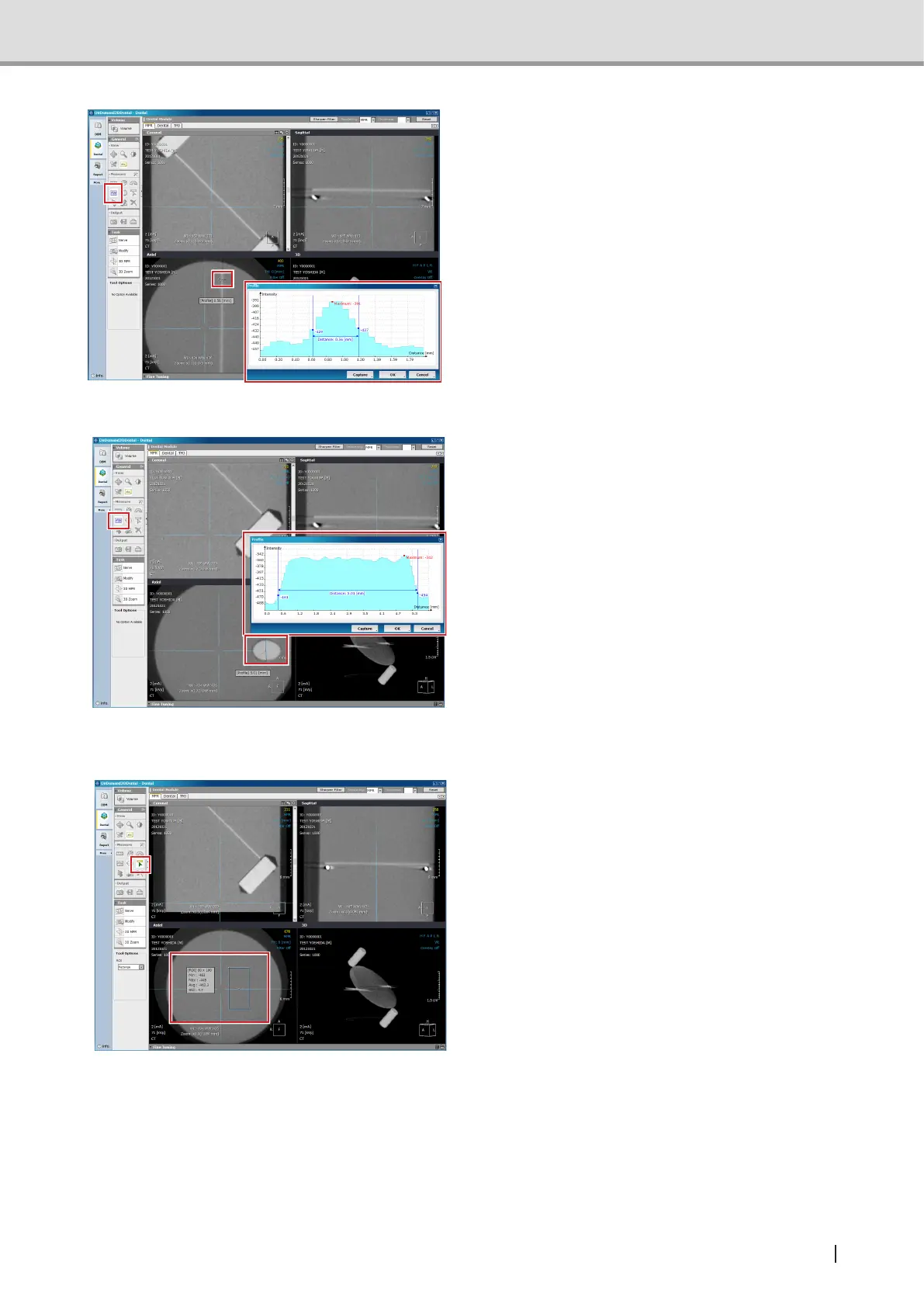

5 Measure the short axis diameter of the

TeonpinfromAxialimage.However,

measure it without adjusting the cross-

bar tilt.

Where to measure is described in the

gurebelow.Measuringpointisaround

thecenterofthelowerTeonpin.Usethe

prolefunctiontosettheproleoftheshort

axisdiameteroftheTeonpinshowninthe

Axial image. Measure the width between

the initial rising points in the graph.

Acceptance value 4.6mm to 5.3mm (stan-

dard value 5.0mm)

6 Find out the standard deviation of pixel

values of the acrylic part from the Axial

image. However, measure it without

adjusting the crossbar tilt.

Where to measure is described in the

gurebelow.Measuringpointisbetween

thebottomedgeoflowerTeonpinandthe

bottom edge of the image.Use ROI function

to read the Std value when acrylic part

shown in the Axial image is surrounded

by the size of 80 x 160. As shown in the

gurebelow,avoidthecenteroftheAxial

image when locating the surrounding area

with ROI.

Acceptance value:

ForImageCreatorVersion2.52orearlier:

10 or less

ForImageCreatorVersion2.53orlater:

120 or less

Loading...

Loading...