INSTALLATION

Page 18

.

5.4 CONTROL HEADS

See Appendix A Control Head Dimensions and Variations for location

of cutout and mounting holes for the Control Heads used with this

application. Refer only to the following Sections that relate to the

Control Heads used.

5.4.1 Mounting

400 Series Control Head:

A) Use the template supplied in Appendix A and drill the screw holes

and the corner cutout holes.

B) Saw between the corner cutout holes.

C) Check that the four mounting screws will start into the Control

Head.

D) Remove the Control Head.

E) Strip the adhesive cover from the gasket and apply the adhesive

side to the console.

700 Series Control Head:

A) Drill the screw holes and the cable holes.

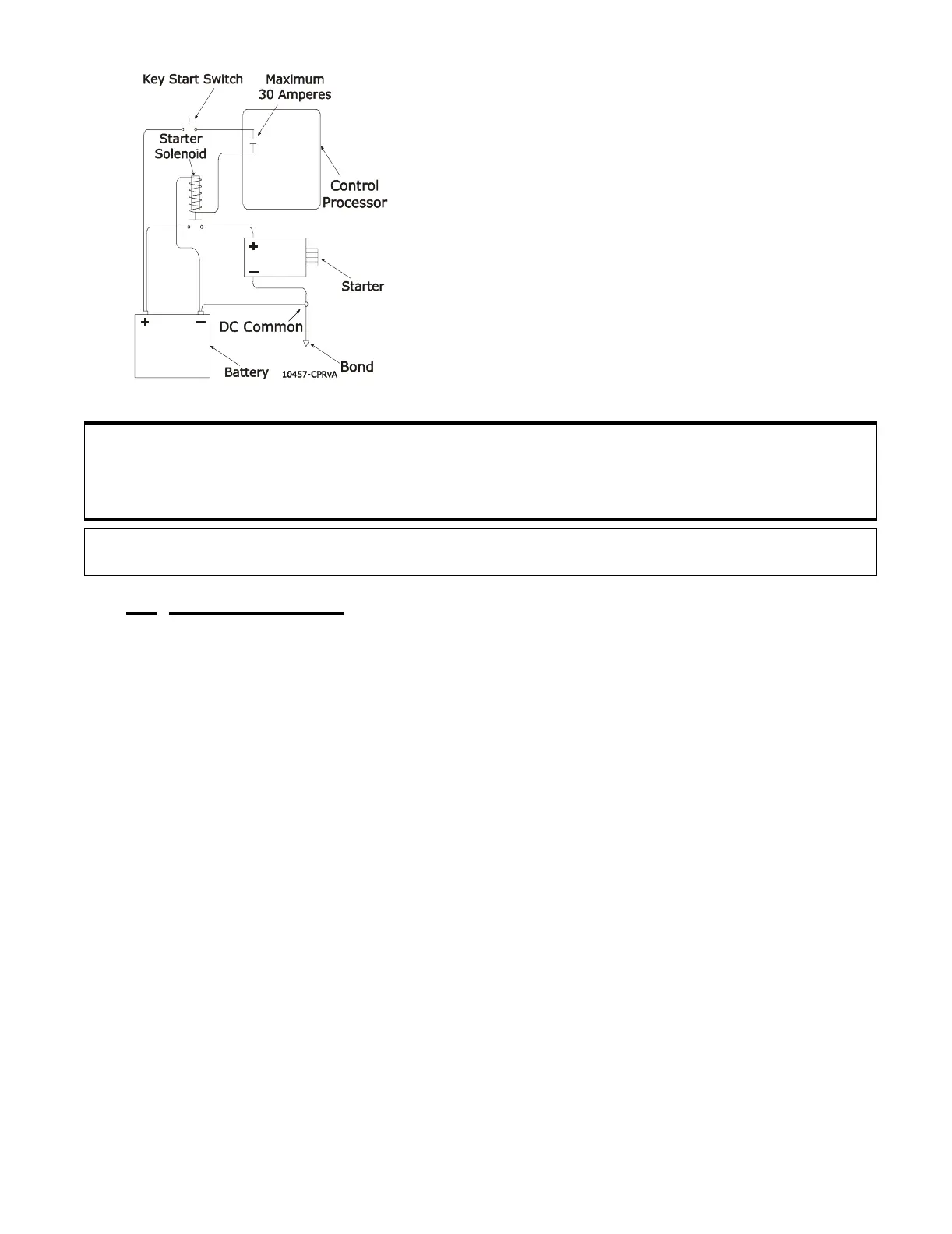

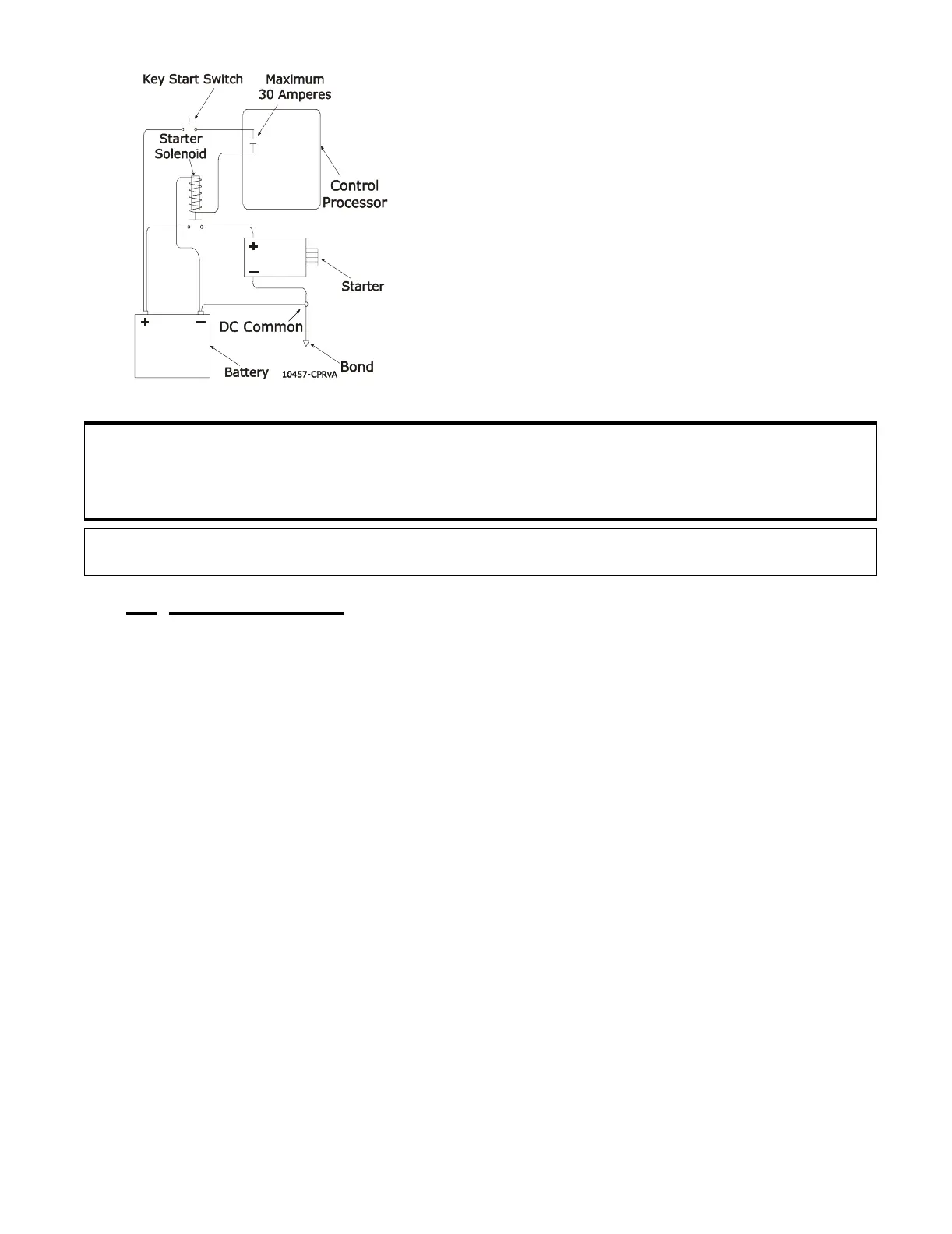

B) Run the two-conductor start interlock

cable through the watertight cable grip.

C) Strip insulation off of each wire 3/8-inch

(9,5mm), then install crimp terminals.

D) Connect the two-conductor cable as indi-

cated on the Drawing in Appendix C.

E) Feed through a little slack cable and

tighten the cable grip

F) Tie wrap the start interlock cable to the

Processor frame

Figure 9: Start Interlock Connections

CAUTION: The most common source of trouble is loose wiring connections. Verify wiring connec-

tors are properly crimped and cannot be pulled out. Crimps and connections must be

made to the wire, not to the wire insulation. Verify all screwed wire connections are

secure.

NOTE: Repeat for all Processors. Ensure all connections at the Processor are as indicated on the

Drawing in Appendix C.

Loading...

Loading...