42 Control macros

Notes:

1)

See parameters 40.19 Set 1 internal setpoint sel1and 40.20 Set 1 internal setpoint

sel2 source table.

2)

Select the correct control mode from the Motor data view or with parameter 99.04

Motor control mode.

3)

PID: 0…10 V -> 0…100% PID setpoint.

4)

The signal source is powered externally. See the manufacturer’s instructions. To

use sensors supplied by the drive aux. voltage output, see connection examples of

two-wire and three-wire sensors in the hardware manual of the drive.

5)

Ground the outer shield of the cable 360 degrees under the grounding clamp on

the grounding shelf for the control cables.

6)

Select the unit for analog input AI1 in the parameter 12.15 and for AI2 in the

parameter 12.25.

Input signals

• PID set point (AI1)

• Process feedback (AI2)

• Start/stop selection (DI1)

• Internal setpoint selection 1 (DI2)

• Internal setpoint selection 2 (DI3)

• Constant speed selection 1 (DI4)

Output signals

• Digital output: Running

• Relay output: Fault(-1)

• Analog output AO: Output frequency

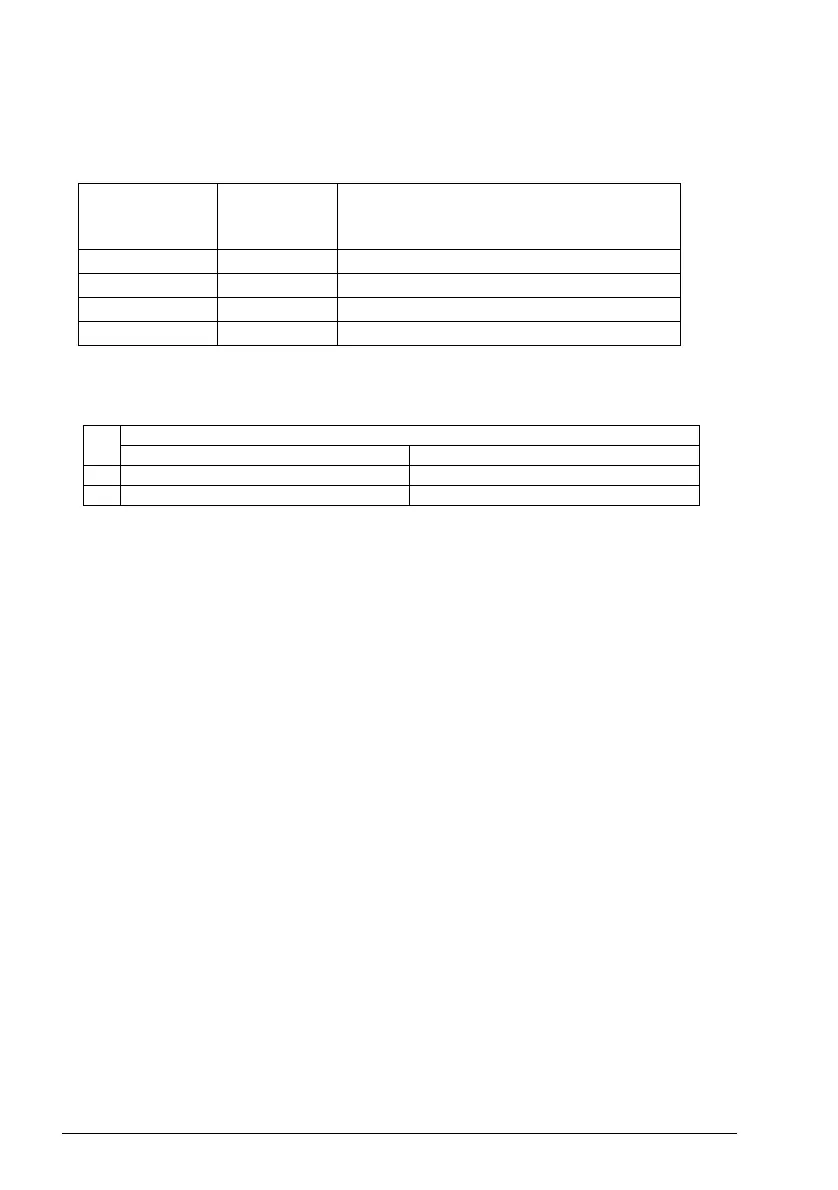

Source defined

by par. 40.19

DI2

Source defined

by par. 40.20

DI3

Internal setpoint active

00

Setpoint source: AI1 (par.40.16)

10

Internal setpoint 1 (par. 40.21)

01

Internal setpoint 2 (par. 40.22)

11

Internal setpoint 3 (par.40.23)

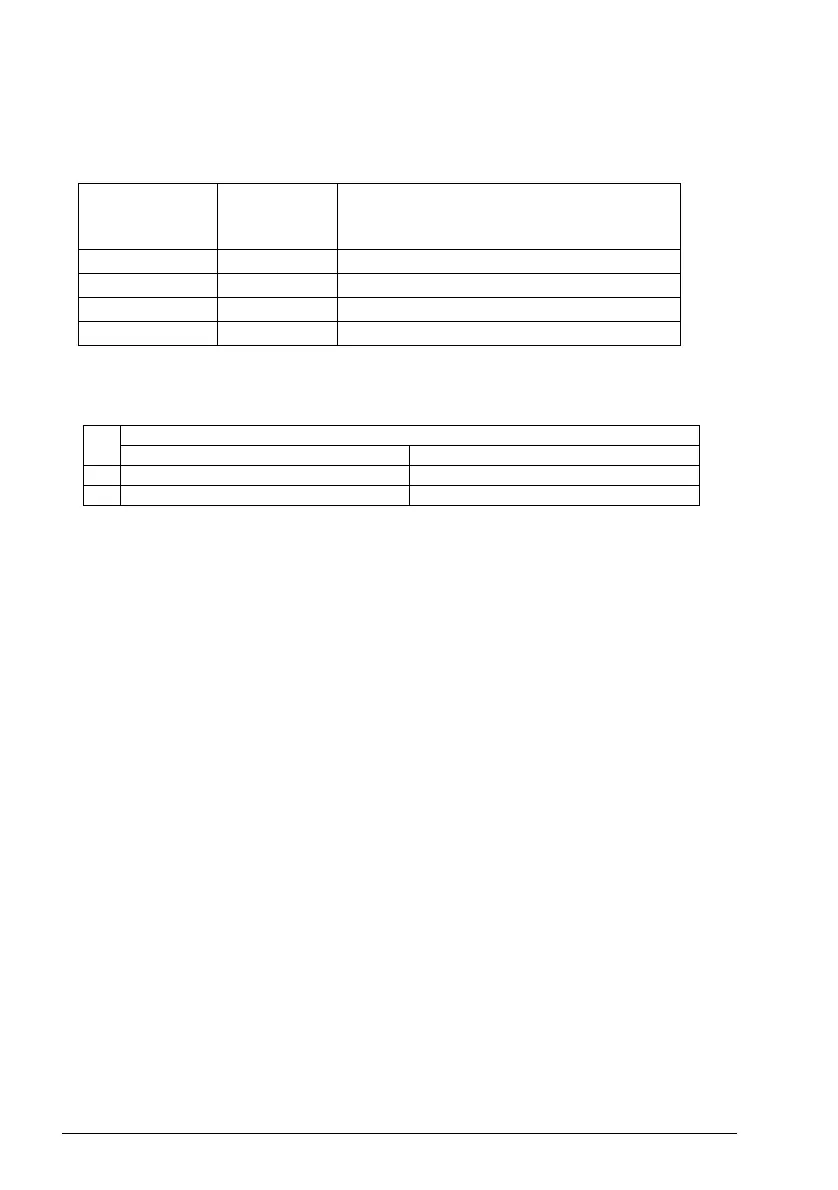

DI4 Operation/Parameter

Scalar control (default) Vector control

0 Set frequency through AI1 Set speed through AI1

1 28.26 Constant frequency 1 22.26 Constant speed 1

ACS180 FW.book Page 42 Tuesday, March 9, 2021 2:25 PM

Loading...

Loading...