74 Program features

metal process industries, infeed and outfeed of rotogravure printing machines, and

surface winders.

The examples provided in this chapter are based on PID set 1. You can set the

desired values for the PID trim function parameters to get the expected result.

When PID trim is activated, bit 5 Trim mode is set to 1 in parameter 40.06 Process

PID status word.

See the speed, torque and frequency reference chains in chapter 10 Control chain

diagrams for more information on the PID trim addition to the respective reference

chains.

The following PID trim modes are available:

• Direct

• Proportional

• Combined.

Direct

The direct method is suitable when you need tension control at fixed rpm/line speed.

In this mode, the PID trim output (parameter 40.05 Process PID trim output act) is

relative to the maximum speed (parameter 30.12 Maximum speed), torque (30.20

Maximum torque 1) or frequency (30.14 Maximum frequency). You can make the

selection with parameter 40.52 Set 1 trim selection.

The calculated trimmed output actual is the same throughout the speed range with

respect to the stable PID output.

The 40.05 Process PID trim output act value is calculated using the following formula:

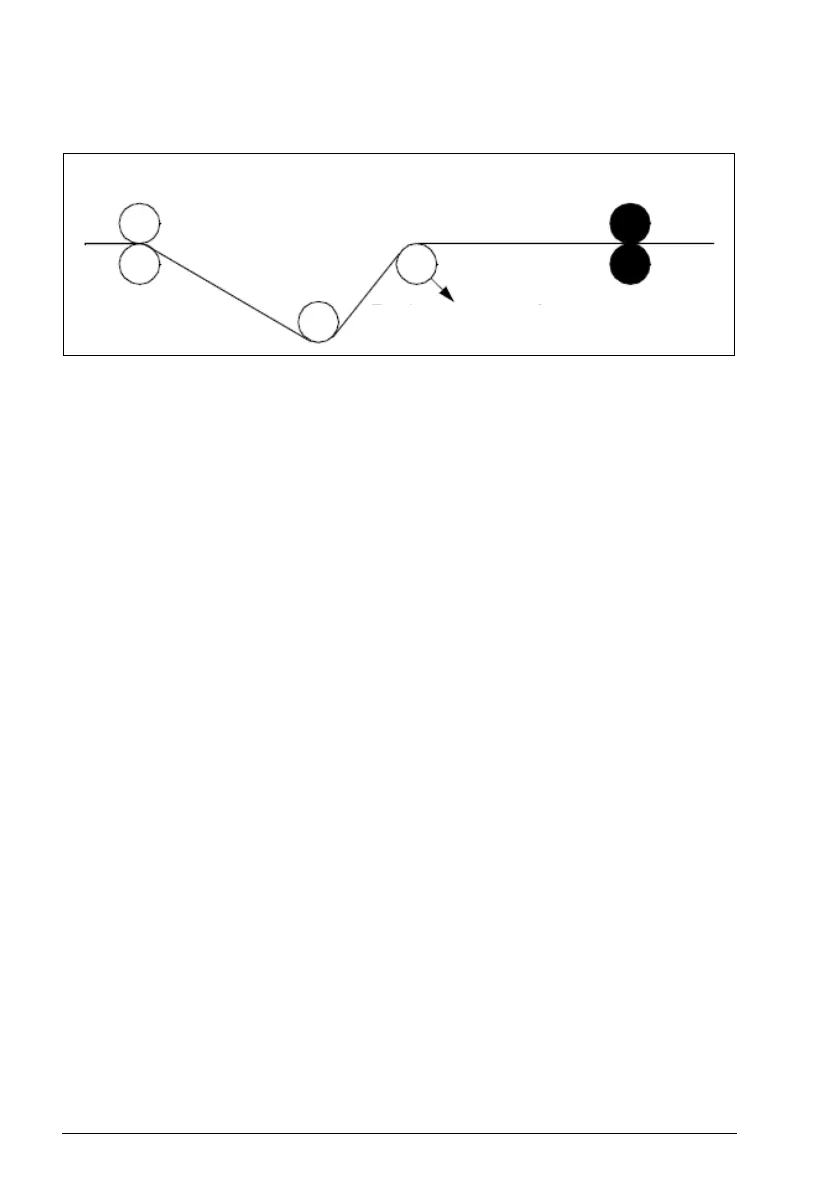

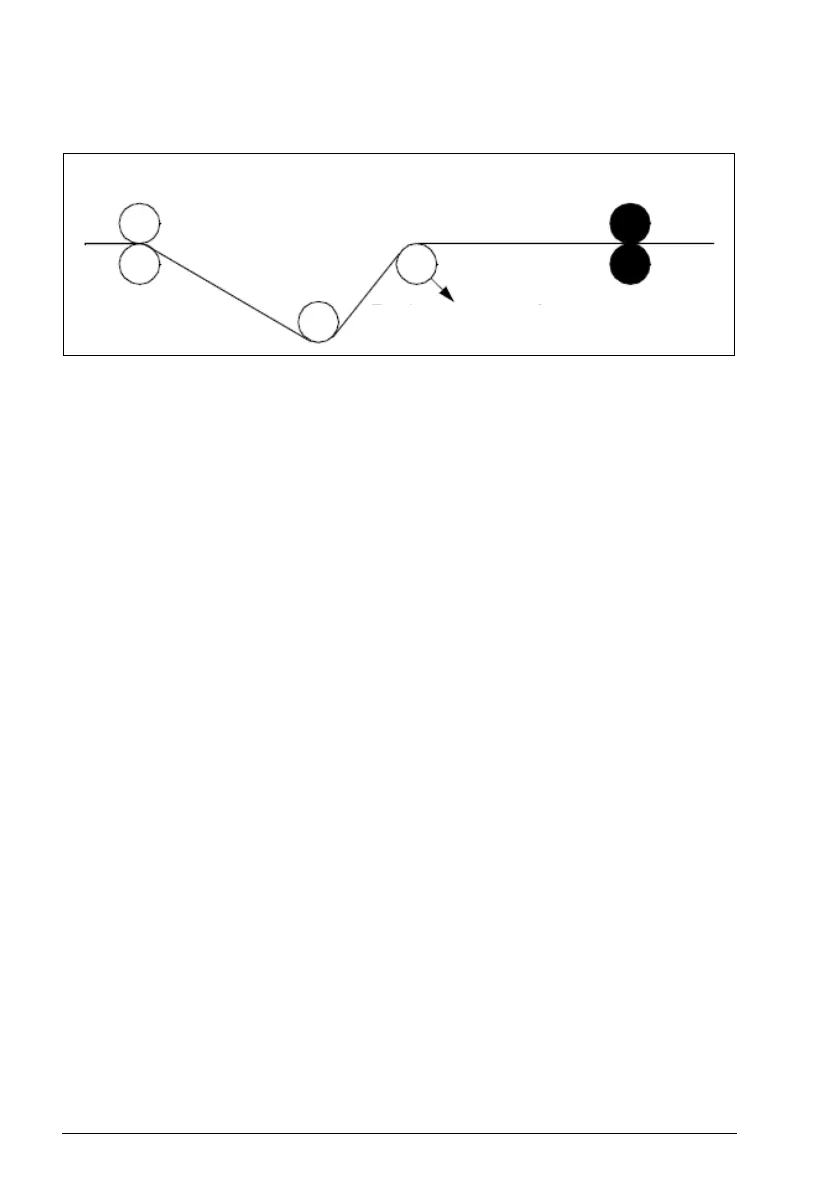

Tension measurement

Drive rollers (pull)

Speed controlled conveyor line

Par40.05

Par40.01

100

------------------------

Par30.12 or 30.20 or 30.14 Par40.55=

ACS180 FW.book Page 74 Tuesday, March 9, 2021 2:25 PM

Loading...

Loading...