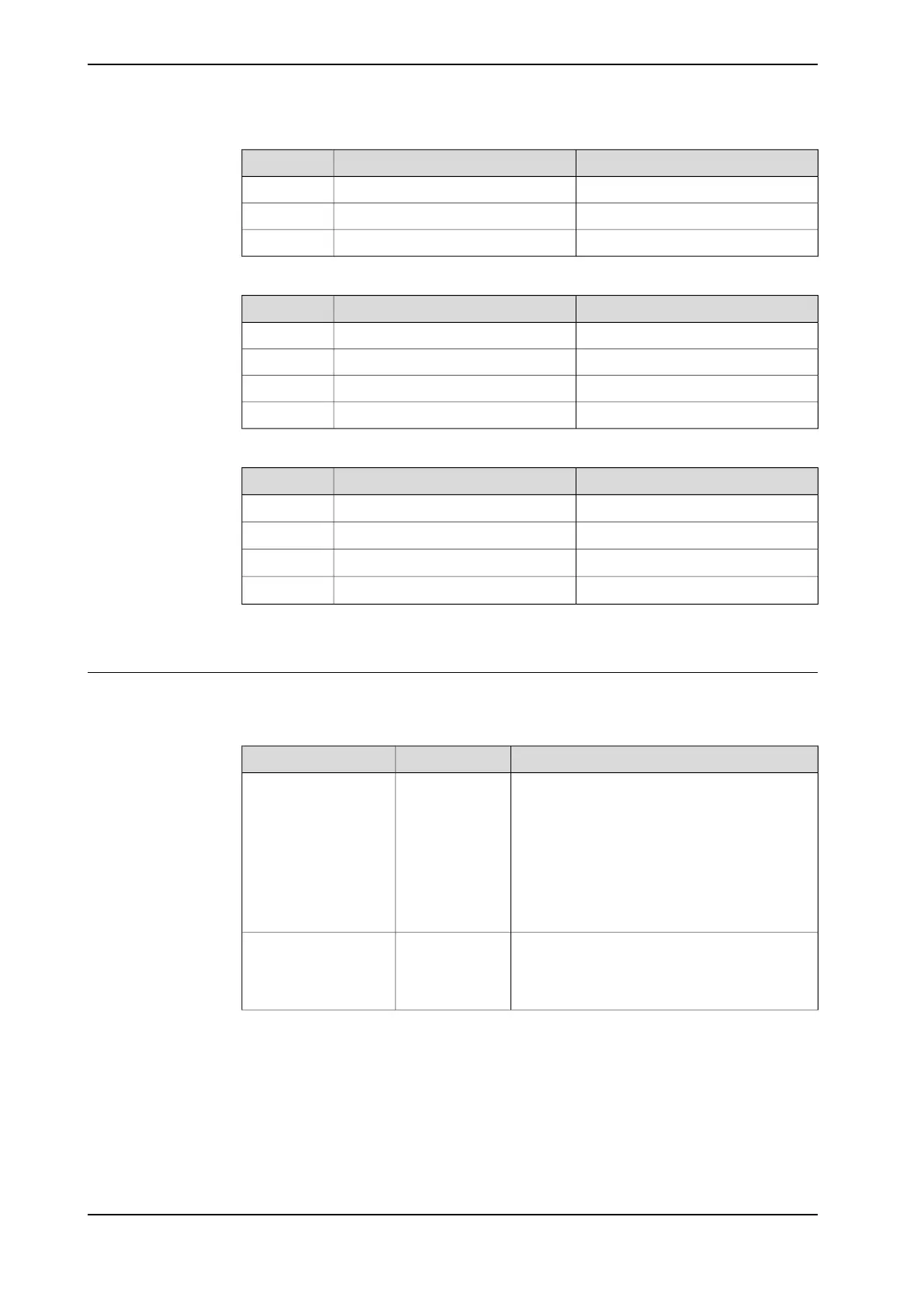

Max. load (emergency stop)Endurance load (in operation)Force

2750 ±3970 N2750 ±1420 NForce z

±7690 Nm±3360 NmTorque xy

±3050 Nm±1120 NmTorque z

Wall mounted

Max. load (emergency stop)Endurance load (in operation)Force

2750 ±4600 N2750 ±880 NForce xy

±4560 N±1780 NForce z

1470 ±5620 Nm1470 ±1990 NmTorque xy

±3130 Nm±1150 NmTorque z

Suspended

Max. load (emergency stop)Endurance load (in operation)Force

±5380 N

i

±2250 N

i

Force xy

-2750 ±4280 N

i

-2750 ±1420 N

i

Force z

±7800 Nm

i

±3440 Nm

i

Torque xy

±3050 Nm

i

±1110 Nm

i

Torque z

i

Only valid for IRB 2600-20/1.65, IRB 2600-12/1.65, IRB 2600-12/1.85, IRB 2600ID-15/1.85, IRB

2600ID-8/2.0.

IRB 2600 Type C-20/1.65, IRB 2600 Type C-12/1.65 is not available for suspended installation.

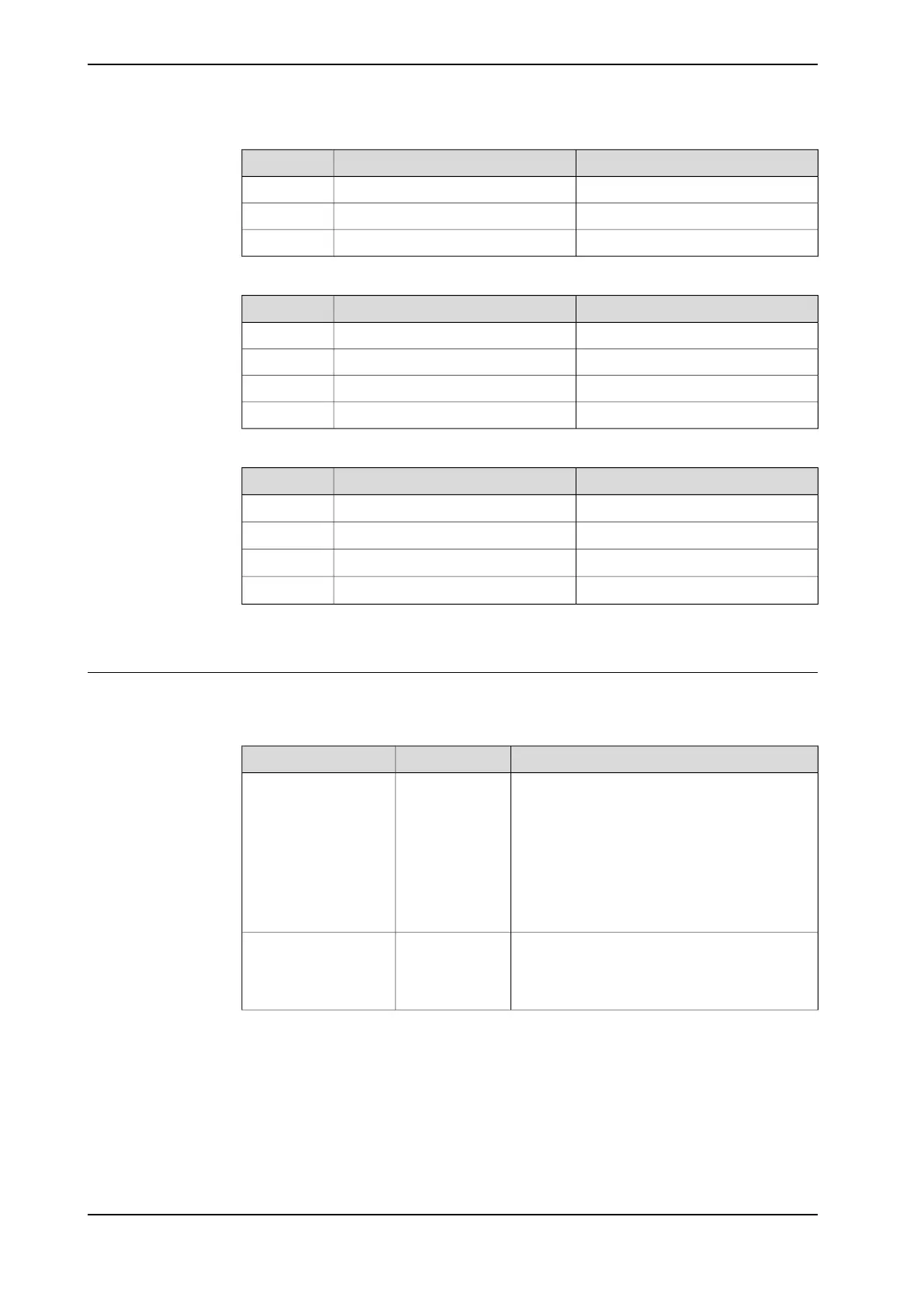

Requirements, foundation

The table shows the requirements for the foundation where the weight of the

installed robot is included:

NoteValueRequirement

Flat foundations give better repeatability of the

resolver calibration compared to original settings

on delivery from ABB.

0.5 mmFlatness of foundation

surface

The value for levelness aims at the circumstance

of the anchoring points in the robot base.

In order to compensate for an uneven surface,

the robot can be recalibrated during installation.

If resolver/encoder calibration is changed this

will influence the absolute accuracy.

The limit for the maximum payload on the robot

is reduced if the robot is tilted from 0°.

15°Maximum tilt

Contact ABB for further information about accept-

able loads.

Continues on next page

52 Product manual - IRB 2600

3HAC035504-001 Revision: Q

© Copyright 2009-2018 ABB. All rights reserved.

2 Installation and commissioning

2.2.1 Pre-installation procedure

Continued

Loading...

Loading...