108 Maintenance

Recommended annual maintenance actions by the user

ABB recommends these annual inspections to ensure the highest reliability and optimum

performance.

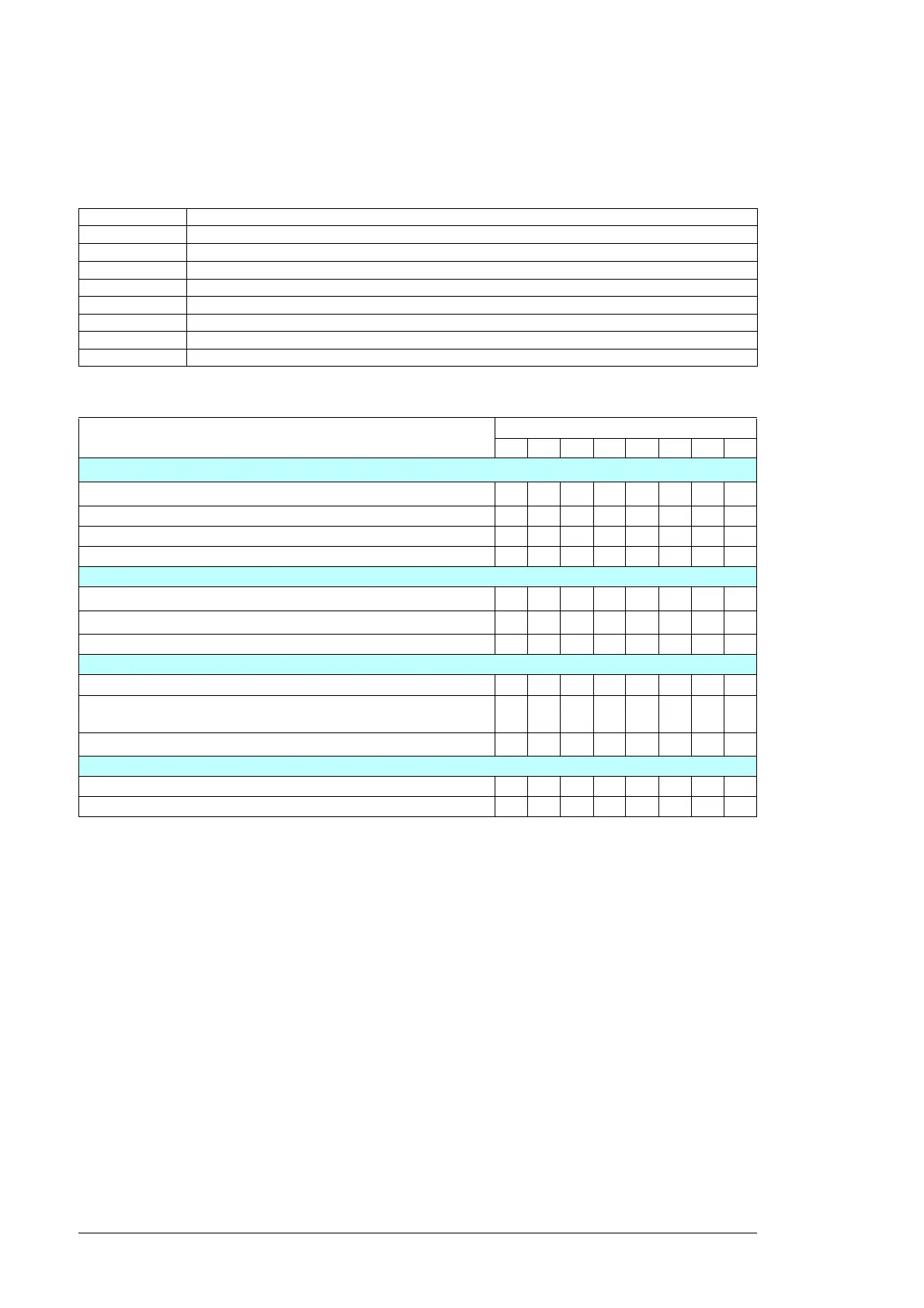

Recommended maintenance intervals after start-up

1) If the inverter is continuously used for reactive power compensation during the night, halve the replacement

interval accordingly. If reactive power compensation is used only partially, check the operating hours of fans

in the Inverter control program parameter 01.31 FAN ON-TIME. Reset the counter when the fans are

replaced.

2) Estimated maintenance interval in ideal conditions: ambient temperature between 0…40° C (104 °F), indoor

conditioned (IEC62109), and no cyclic heavy load.

3) If operation temperature is continuously below 40° C (104 °F), replacement after 12 years. If above 40° C,

replacement after 9 years. Contact ABB for replacement.

Action Target

I Air inlet and outlet meshes on the cabinet doors

R Air filters on the cabinet doors

P Quality of supply voltage

I Spare parts

P Capacitor reforming, spare modules and spare capacitors

I Tightness of terminals

I Dustiness, corrosion or temperature

IHeat sink

Component Years from start-up

3 6 9 1215182021

Cooling

1)

Main cooling fan of inverter module

RRR

Cooling fan of LCL filter R R R

Cabinet cooling fan (roof) R R R

Cabinet cooling fan (door) R R R

Inverter unit

DC circuit electrolytic capacitors and discharging resistors

2)

R

Main circuit interface board

2)

R

Flat ribbon cables R

Control

Memory back-up battery in APBU branching unit R R R

Cabinet temperature measurement sensor and transmitter check

(DRMU-W)

IIIIII I

24 V DC buffer

3)

RR R

Connections and environment

Quick connector of converter module R I R

Checking and cleaning of power connections I I I I I I I

4FPS10000027105

Loading...

Loading...