Basic Installation 3-19MN1902

3.5.5 Motor brake connection

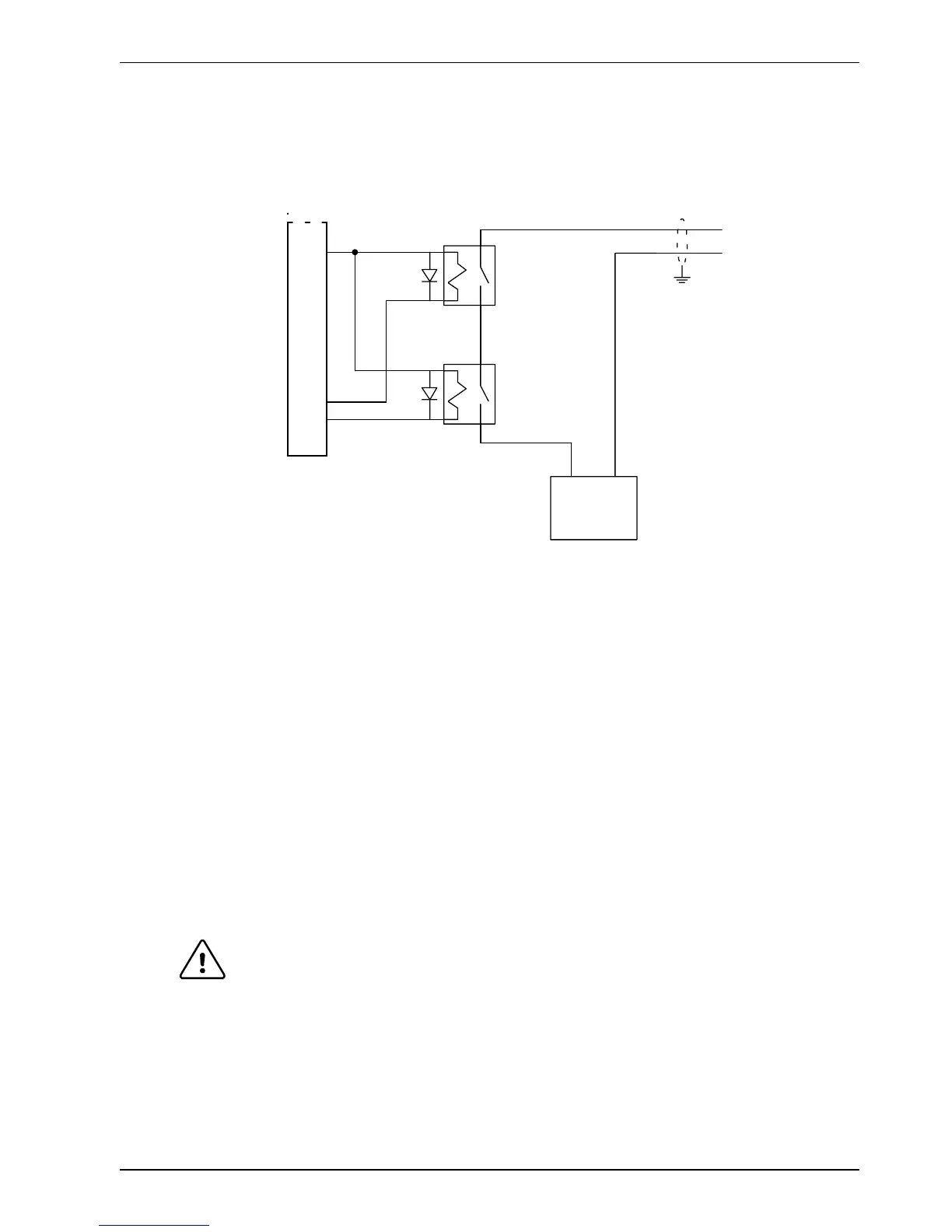

You might wish to wire a motor’s brake, via relays, to digital outputs on connector X3 (see

section 4.3.1). This provides a way for the Mint program to control the motor’s brake. A typical

circuit is shown in Figure 10.

C

D

from motor brake

connec tions

Separate

customer

supplied

24VDC supply

X3

8

18

19

DOUT0 (OUTX.0)

DOUT1 (OUTX.1)

CGND

Relay 2

Relay 1

+24VDC 0V

The i nner s hield

surrounding the

brake wires should

be earthed/grounded

at one point only.

The relay s have normally open

contac ts and are shown deactivated

(contacts open, brake engaged).

Figure 10 - Motor brake control circuit

This circuit uses the drive enable signal (configured using DRIVEENABLEOUTPUT to appear

on DOUT0) in conjunction with DOUT1. With this configuration, the following sequences can

be used to control the brake.

To engage the brake:

H The motor is brought to rest under normal control;

H Relay 2 is deactivated, causing the brake to engage;

H The drive is disabled. This removes power from the motor and causes Relay 1 to be

deactivated.

To disengage the brake:

H The drive is enabled, activating Relay 1;

H Power is applied to the motor to hold position under normal control;

H Relay 2 is activated, causing the brake to be disengaged.

CAUTION: The 24VDC power supply must be a separate supply as shown in Figure

10. Do not use the 24V supply powering the FlexDrive

II

digital outputs, or

the internally generated supply (if present). The brake wires often carry

noise that could cause erratic drive operation or damage. The brake

contacts must never be wired directly to the digital outputs. The relay(s)

should be fitted with a protective flyback diode, as shown.

The separate 24VDC supply used for the motor brake may also be used

to power the relay in the thermal switch circuit (section 3.5.4).

Loading...

Loading...