BAL2185_Grease_lubrication_pump_PICO_with_PICO-troniX1_-tronic_0519EN 10158410

...a product of

© BEKA 201 All !9 rights reserved

24

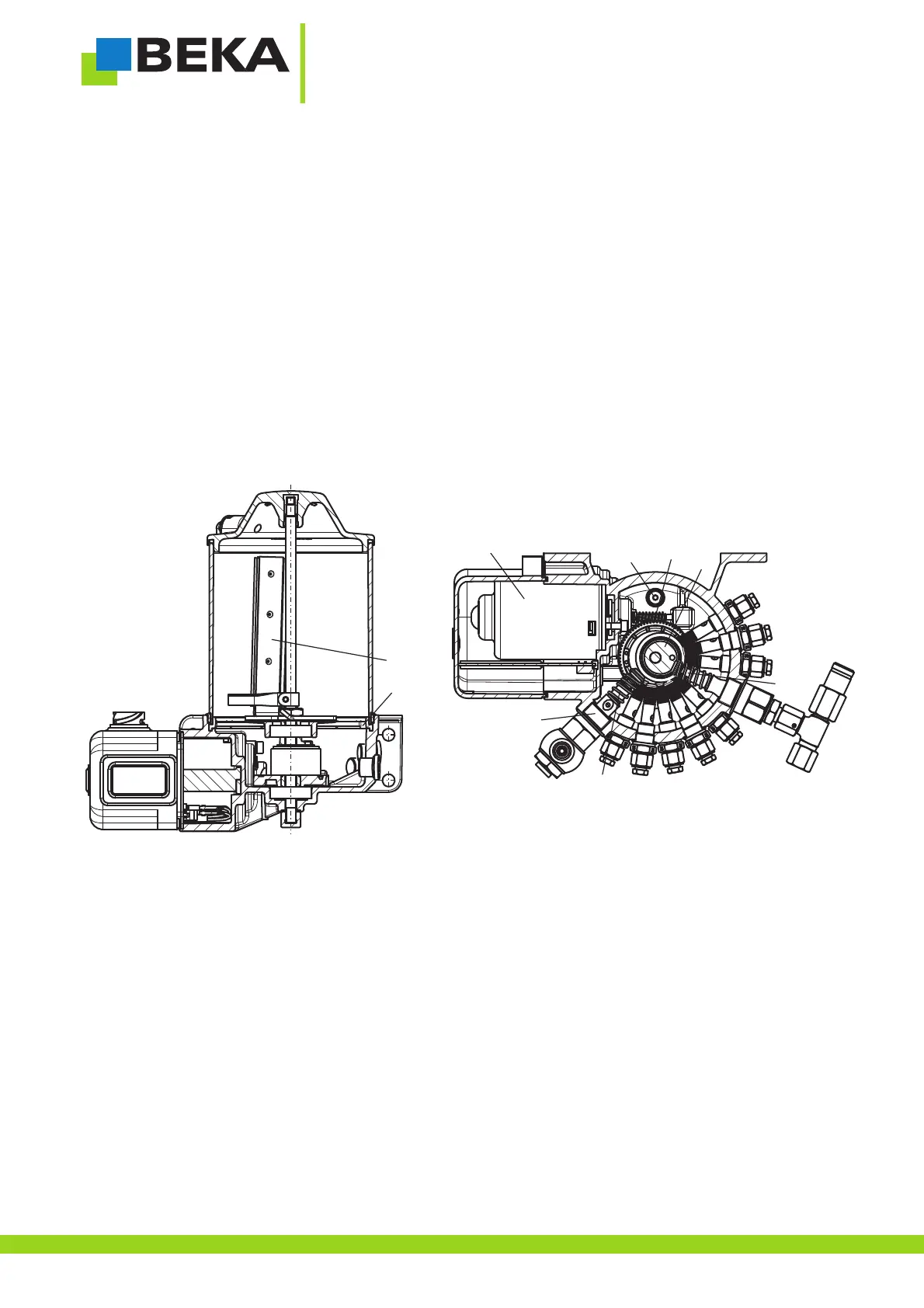

8.3.2 Functionaldescription ofthe versionwith agitatorblade

Thefollowing listedpositions canbe foundin fig.22.

A DC motor optionally with 12 or 24 V DC (pos. 1) drives the eccentric shaft (pos. 3) via a worm drive (pos. 2). The,,

delivery pistons (pos. 4) of the integrated pump elements are pushed into the pump element body (pos. 5) by the rotary

movement and the eccentricity of the shaft (= delivery stroke). The delivery pistons return into their initial position by the

compressionsprings (pos.6) andsuck newlubricant fromthe reservoir(=suction stroke).

Non-return valvesare integrated in thepump elements which preventthat lubricant, which hasalready been displaced, is

sucked back.An agitator blade (pos. 8), which is firmly connected with the eccentric shaft, is located above the centering

ring(pos. 7),which isused asgrease strainer. Theagitatorblade pushesthe lubricanttowards thepump elements.

The device can be filled via a cone-type zerk which is located in the pump housing. In order to avoid an overfilling of the

device,a pressurelimiting valve(pos. 9)is integratedin thepumphousing whichis usedas overfillprotection.

Referto chapter7.2 „Fillingwith lubricant“for furtherinformation onfilling thedevice.

Fig.22:

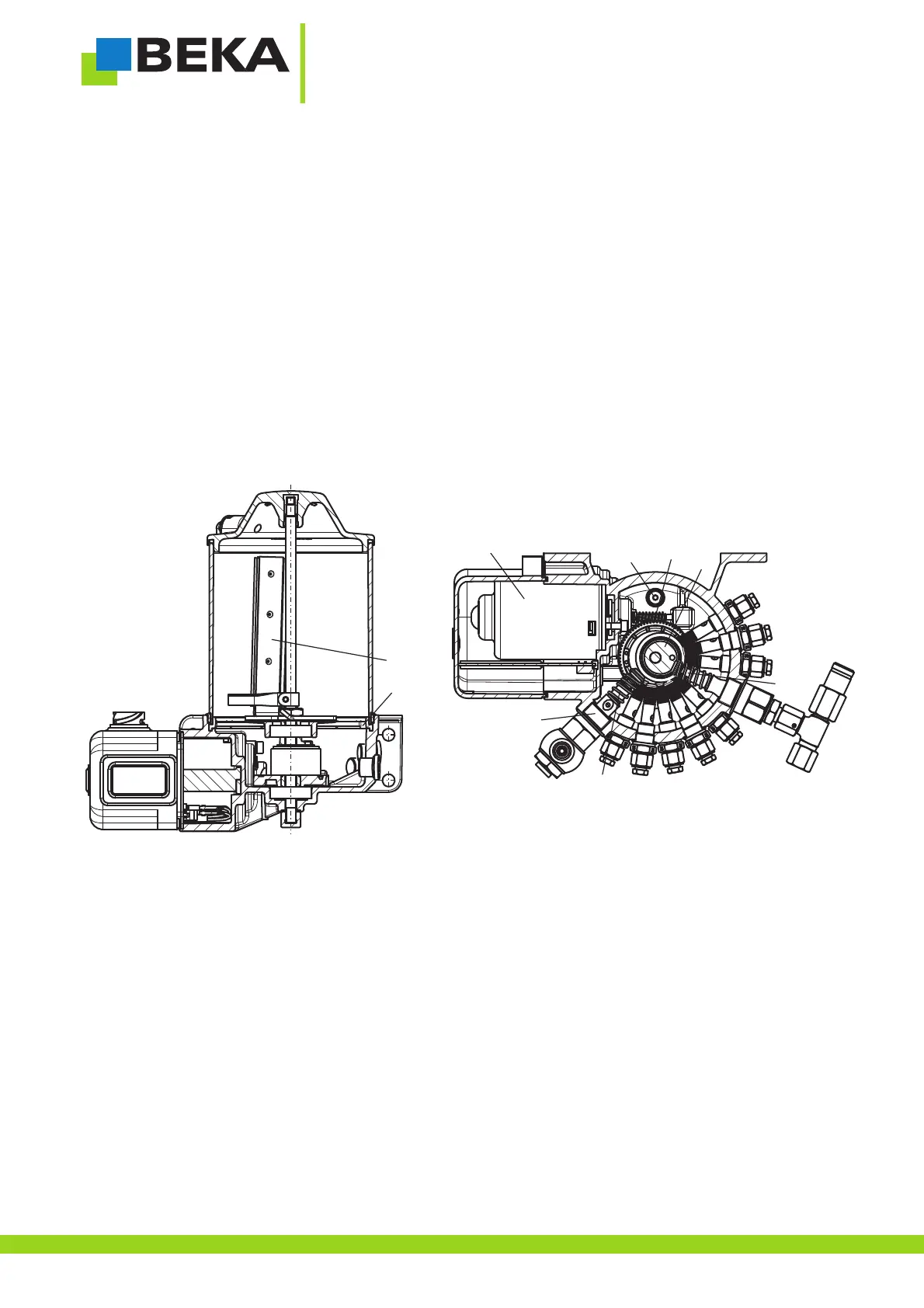

8.4 Pumpelements

Two different construction types of pump elements can be installed into the device, depending on for which lubrication

systemor forwhich lubricationsystem combinationthe deviceis used.

1

2

3

4

5

6

7

8

9

Loading...

Loading...