Operating Instructions ACTIVE 06/07104

104 Operating Instructions ACTIVE 06/07

11.6.1 Reference Positioning

The feedback of the current position is referred to the revolutions of the motors rela-

tive to the time of the reference signal. The accuracy of the positioning for the applica-

tion to be realized is dependent on the current

Actual Frequency 241, the Decelera-

tion (Clockwise)

421, the No. of Pole Pairs 373, the selected Positioning distance

460 and the parameterized control behavior.

The distance between the reference point and the required position is to be defined in

motor revolutions. The calculation of the distance covered is done with the selected

Positioning distance 460 according to the application.

The setting 0.000 U for the

Positioning distance 460 causes an immediate stop of the

drive according to the selected stopping behavior for

Operation Mode 630.

Parameter Settings

No. Description Min. Max. Fact. sett.

460 Positioning Distance 0.000 U 1000000.000 U 0.000 U

The actual value parameter Rotations 470 facilitates the setting and optimization of

the function. The revolutions of the motor displayed should correspond to the

Posi-

tioning distance

460 at the required position.

The minimum number of revolutions needed until the required position is reached de-

pends on the

Actual Frequency 241 and Deceleration (Clockwise) 421 (or Decelera-

tion Anticlockwise

423) as well as the No. of Pole Pairs 373 of the motor.

U

min

= min. number of rotations

f =

Actual frequency 241

a =

Deceleration 421 (423)

pa2

2

f

min

U

⋅⋅

=

p =

No. of Pole Pairs 373 of motor

Example: f = 20 Hz, a = 5 Hz/s, p = 2 ⇒ U

min

= 20

At an actual frequency of 20 Hz and a deceleration of 5 Hz/s, at least 20 revolutions

are required until the drive stops at the required position. This is the minimum value

for the

Positioning distance 460, a shorter positioning distance is not possible. If the

number of revolutions to the required position is to be lower, either the frequency

must be reduced, the deceleration must be increased or the reference point must be

shifted.

The digital signal for acquisition of the reference point and the logic link can be se-

lected by the parameter

Signal Sources 459. The link of the digital inputs S2IND,

S3IND and S6IND to further functions is to be checked according to selected

Configu-

ration

30 (e.g., in configurations 110 and 210, digital input S2IND is linked to the

function "Start of clockwise operation").

The signals for positioning and a stopping behavior should not be assigned to the same

digital input.

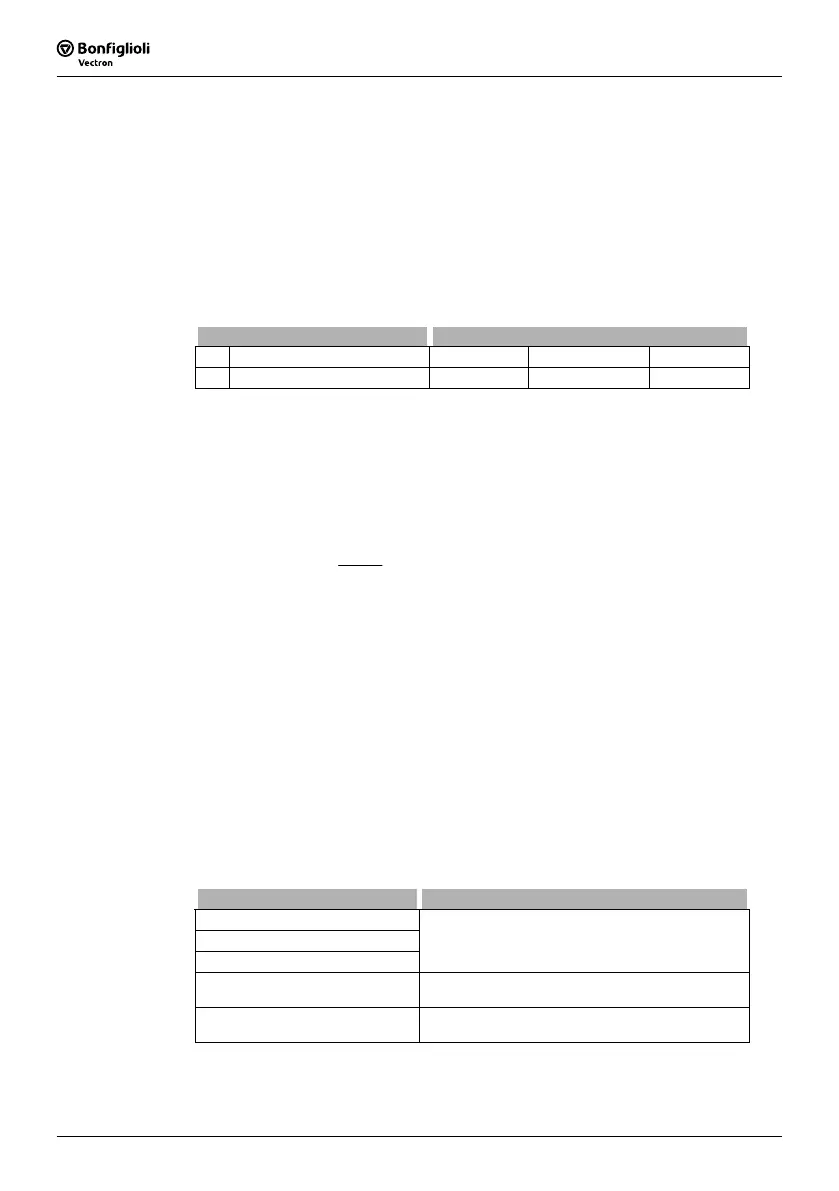

Signal Sources 459 Function

2 - S2IND, falling edge

3 - S3IND, falling edge

6 - S6IND, falling edge

The positioning starts with the change of the logic

signal from 1 (HIGH) to 0 (LOW) at the reference

point.

1x - SxIND, rising edge

The positioning starts with the change of the logic

signal from 0 (LOW) to 1 (HIGH).

2x - SxIND, rising/falling edge

The positioning begins with the change of the

logic signal.

Loading...

Loading...