3-22 Confidential

3.2.2.2 Head maintenance mechanism

[ 1 ] Overview

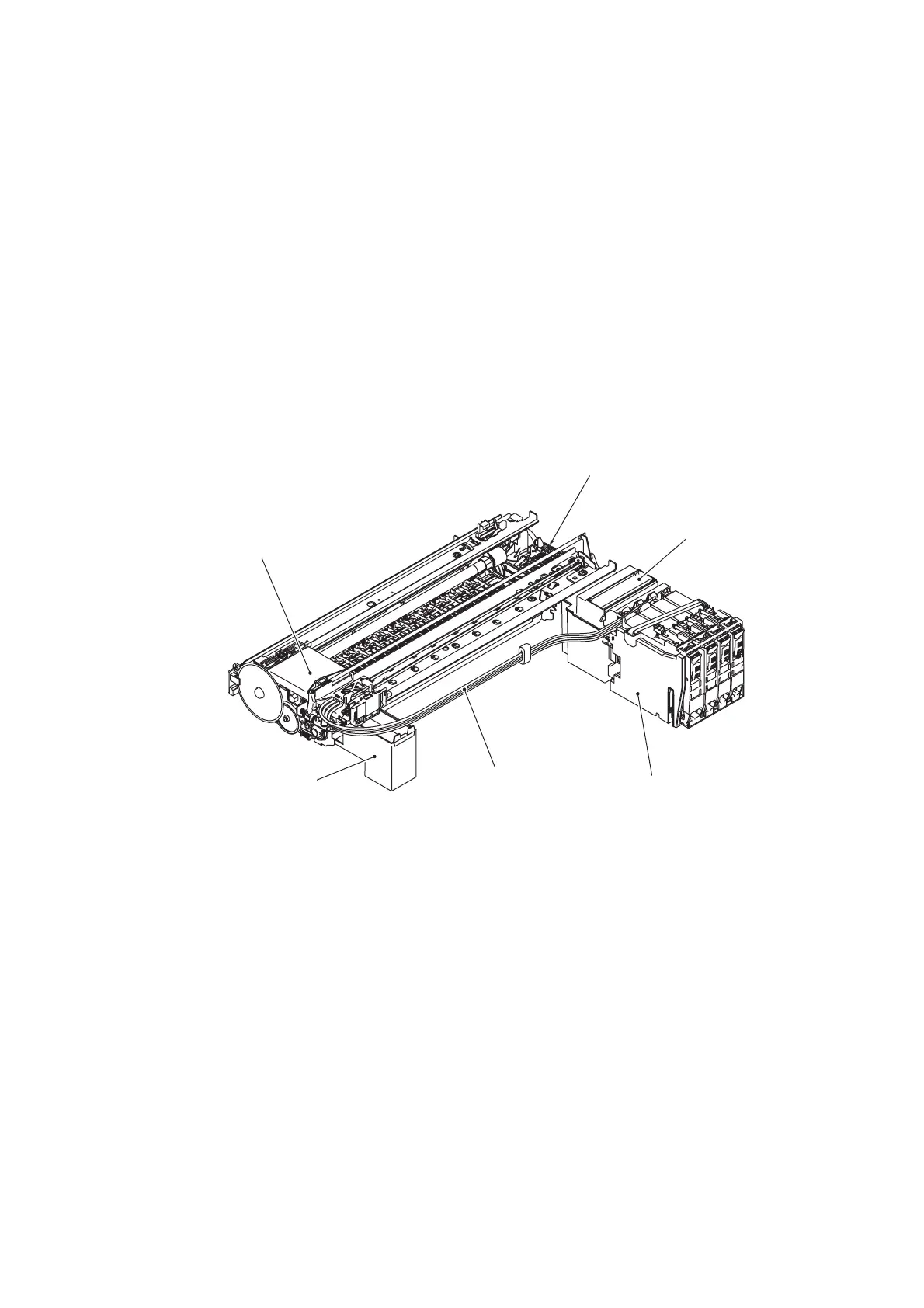

The head maintenance mechanism consists of the maintenance unit and the ink absorber box. (See

the illustration below.)

The maintenance unit has the following mechanisms.

- Head capping mechanism (See page 3-24.)

- Carriage lock mechanism (See page 3-25.)

- Purge mechanism (See page 3-25.)

- Head wiper mechanism (See page 3-27.)

- Air removing mechanism (See page 3-28.)

The ink absorber box absorbs the ink sucked out by purge operations.

(3_05)

(Head/carriage unit)

Flushing box

(Ink supply tubes)

(Ink refill assembly)

Ink absorber box

Maintenance unit

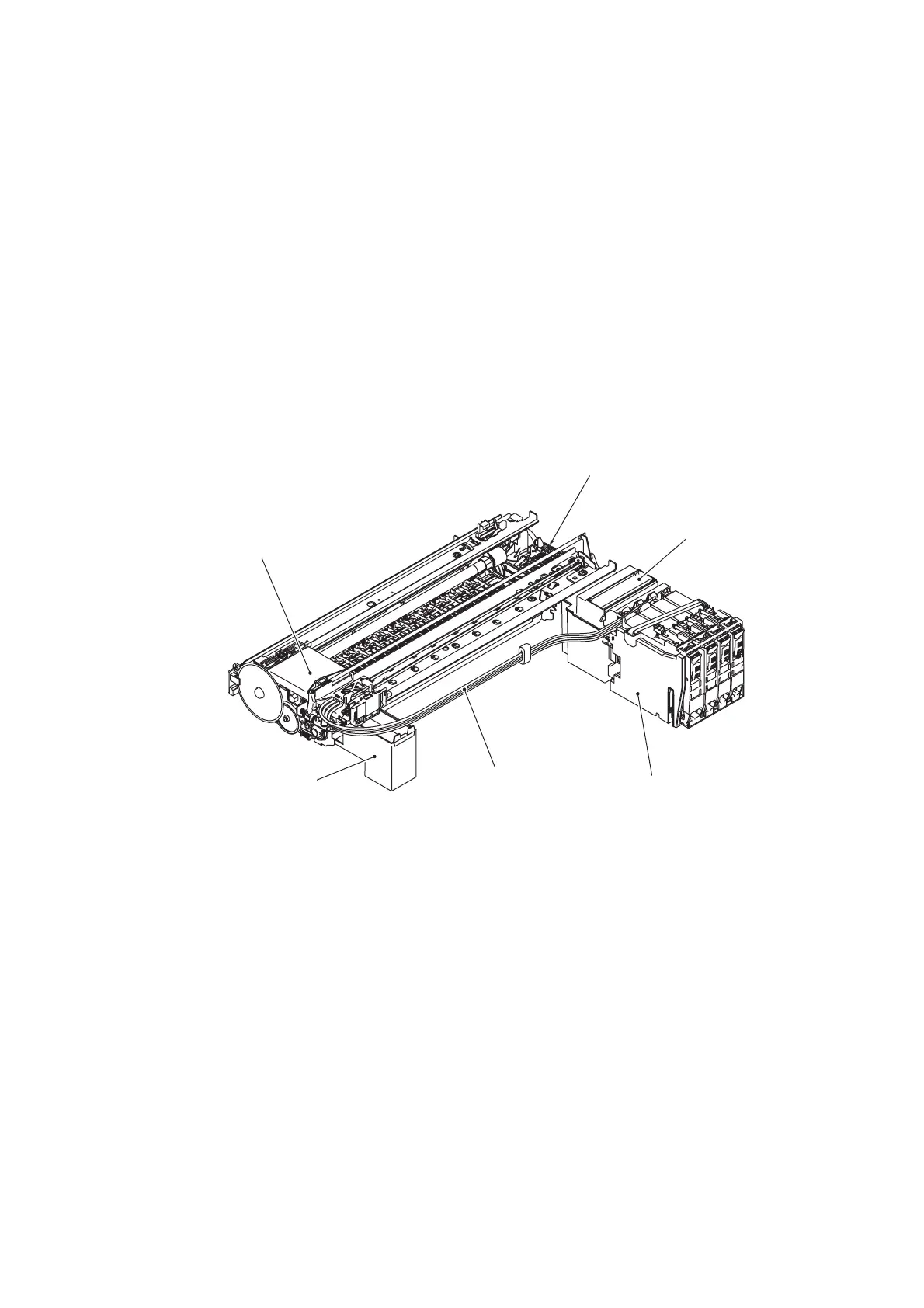

[ 2 ] Maintenance unit components

See the illustration given on the next page.

- Pump switching unit

This switches the application target of the negative pressure generated by the tube pump (see the

next page) between the head cap for black ink, the one for color ink, and the air vent cap. Usually

the pump switching unit is switched to the opening tube to the atmospheric air so that the

pressure in the head caps and air vent cap is equal to the normal atmospheric pressure.

- Purge cam

This rotating cam drives the carriage lock, the pump switching unit, the air vent rods, the head

wiper, etc.

- Head/carriage lock

This locks the head/carriage unit in its home position so that the head cap unit (see the next page)

protects the head nozzles.

Loading...

Loading...