3-44 Confidential

3.2.3 Sensors and Actuators

This machine uses the following sensors and thermistors.

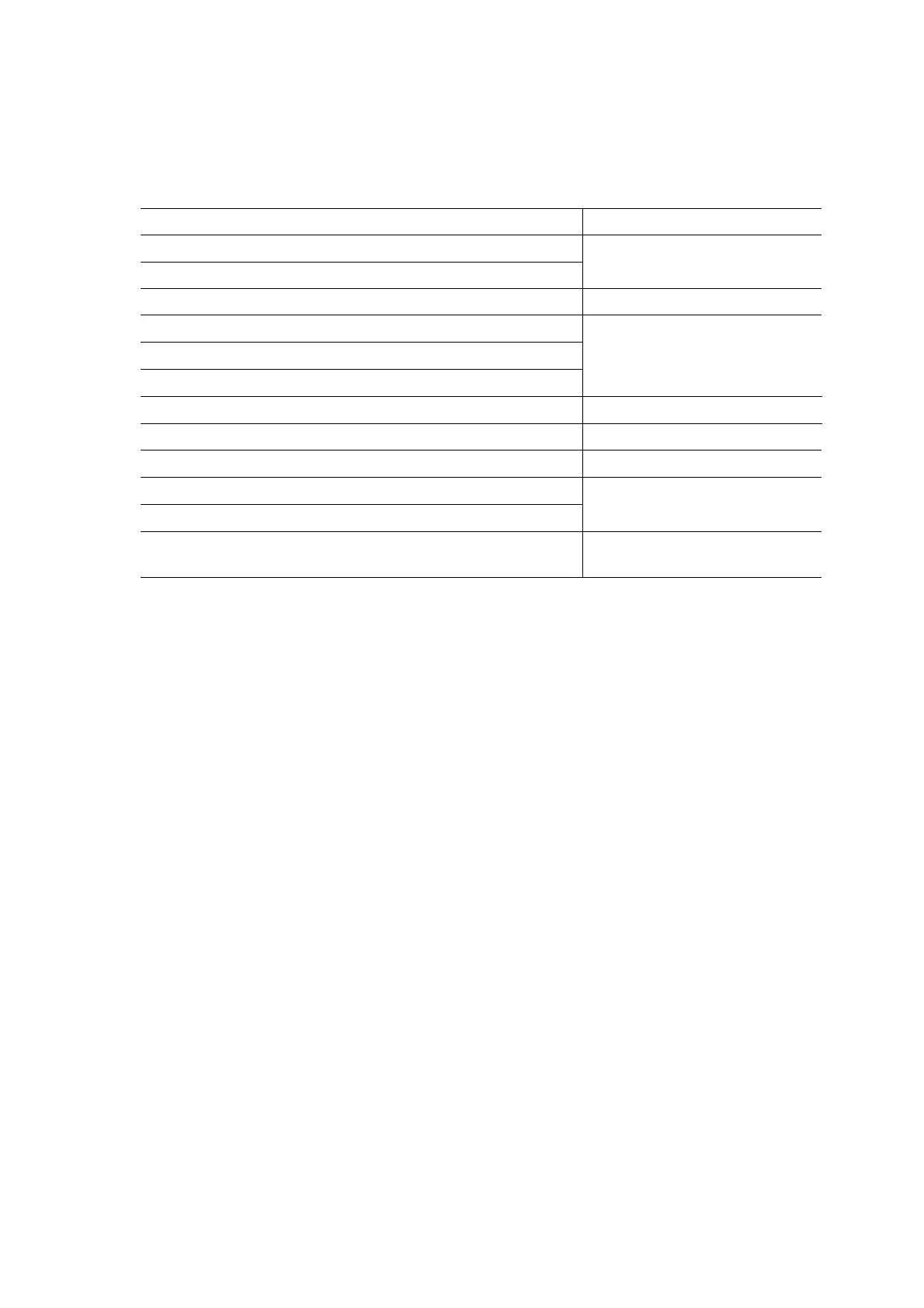

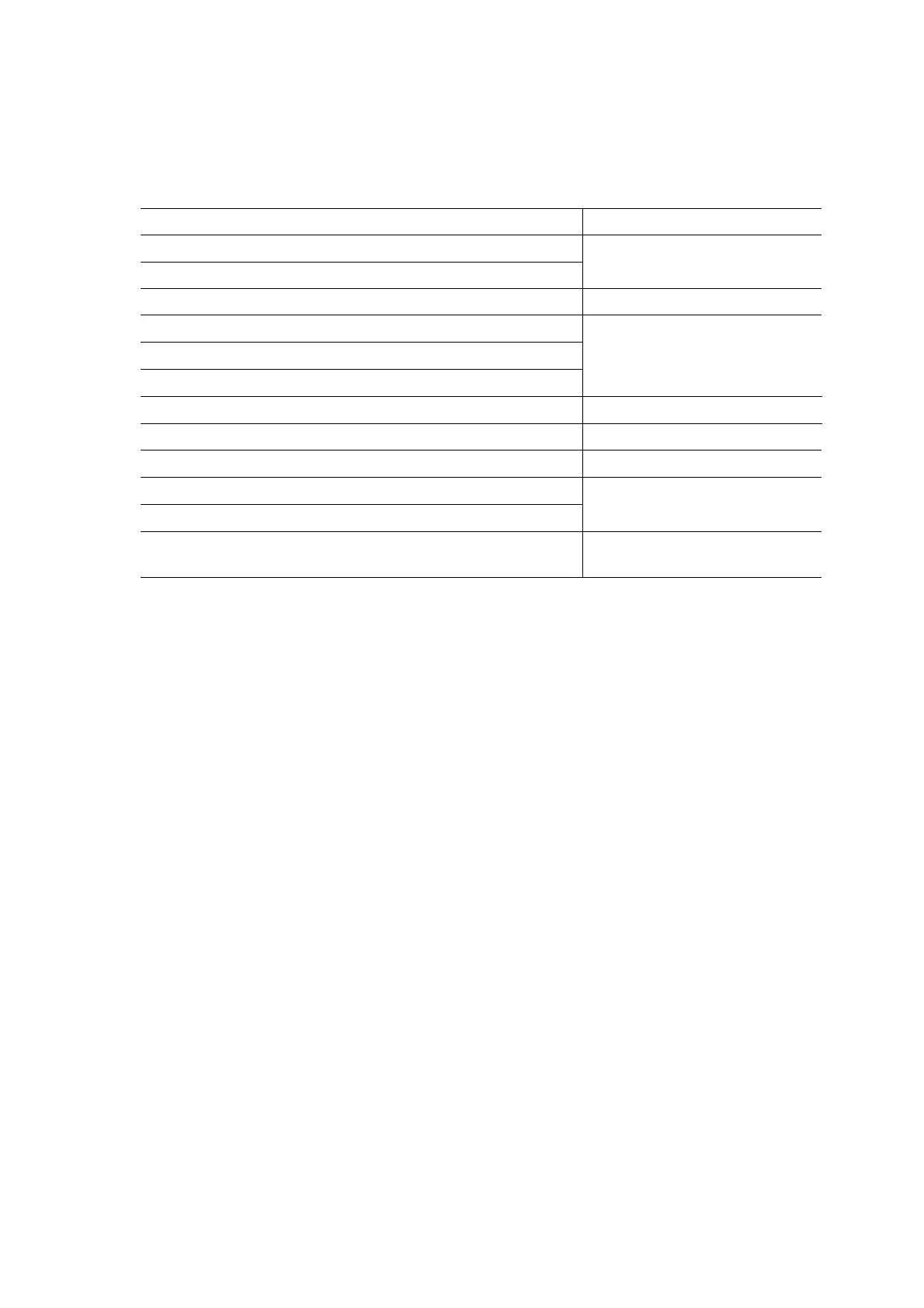

Sensor Name Sensor Type Location

Document front sensor*

1

Photosensor

Document rear sensor*

1

Photosensor

In the ADF unit

*

1

Scanner/ink cartridge cover sensor Photosensor On the cover sensor PCB

Paper width sensor (media sensor) Photosensor

Head thermistor Thermistor

CR encoder sensor Photosensor

On the carriage PCB

Registration sensor Photosensor On the registration sensor PCB

PF encoder sensor Photosensor On the PF encoder PCB

Purge cam switch Mechanical switch On the maintenance unit

Ink cartridge sensors (four) Photosensor

Casing internal temperature thermistor Thermistor

On the ink cartridge PCB inside

the ink refill assembly

Hook switch*

2

Photosensor

On the hook switch PCB

*

2

in

the lower cover

*

1

For models with ADF

*

2

For models with handset

• The document front sensor detects whether there is a document in the ADF.

• The document rear sensor detects the leading and trailing edges of document pages, indicating to

the control circuitry the point at which to start reading and when page scanning is complete.

• The scanner/ink cartridge cover sensor detects whether the scanner cover (scanner unit) and the

ink cartridge cover are properly closed.

• The paper width (media) sensor detects the size of recording paper. With this sensor signal, the

controller prevents the print head from printing on the outside of paper in borderless printing. It

also protects the platen from no-paper printing when a paper jam occurs, preventing stains on the

platen and the back side of paper.

• The head thermistor detects the temperature of the print engine. According to the sensor

information, the controller adjusts the head driver to compensate for changes in ink viscosity.

• The carriage motor (CR) encoder sensor monitors the head/carriage unit's current position and

speed. If the controller detects a head's travel speed error, it interprets the error state as a paper

jam and stops the operation.

• The registration sensor detects the leading and trailing edges of paper for use in determining print

start and end timings and detecting paper jams.

• The paper feed motor (PF) encoder sensor monitors the PF roller rotation angle and speed for

use in optimizing paper feed amount and speed.

• The purge cam switch detects the drive positions of the purge cam.

• There are four ink cartridge sensors, one for each color. The sensor actuator inside the ink

cartridge usually blocks the light path to indicate the presence of ink. When ink runs low (near-

empty), the arm moves out of the beam, activating the sensor. The same signal also indicates

whether there is an ink cartridge present.

Loading...

Loading...