II - 1

CHAPTER II THEORY OF OPERATION

2.1 OUTLINE OF MECHANISMS

2.1.1 Print Mechanism

■ Structure of Thermal Head

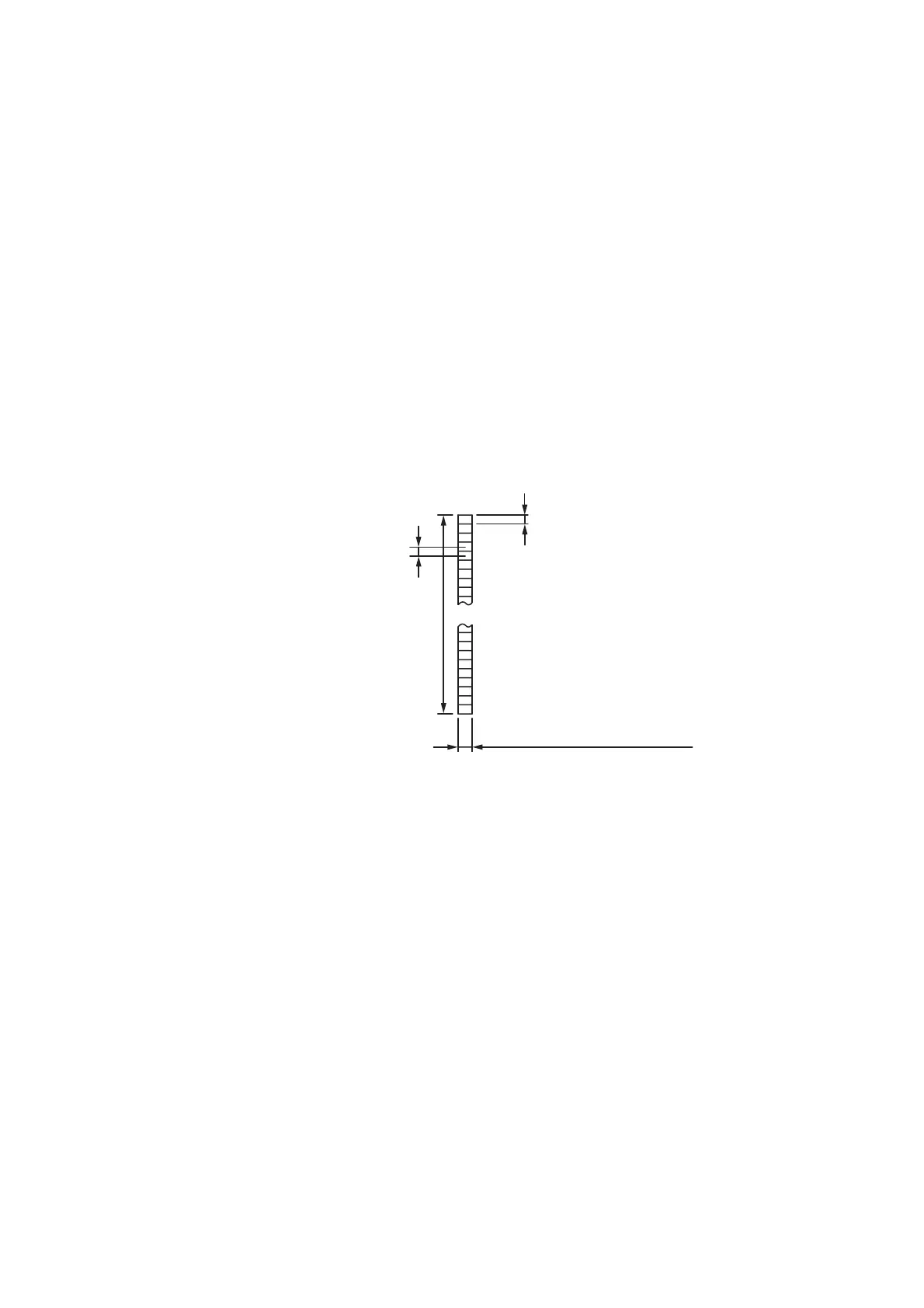

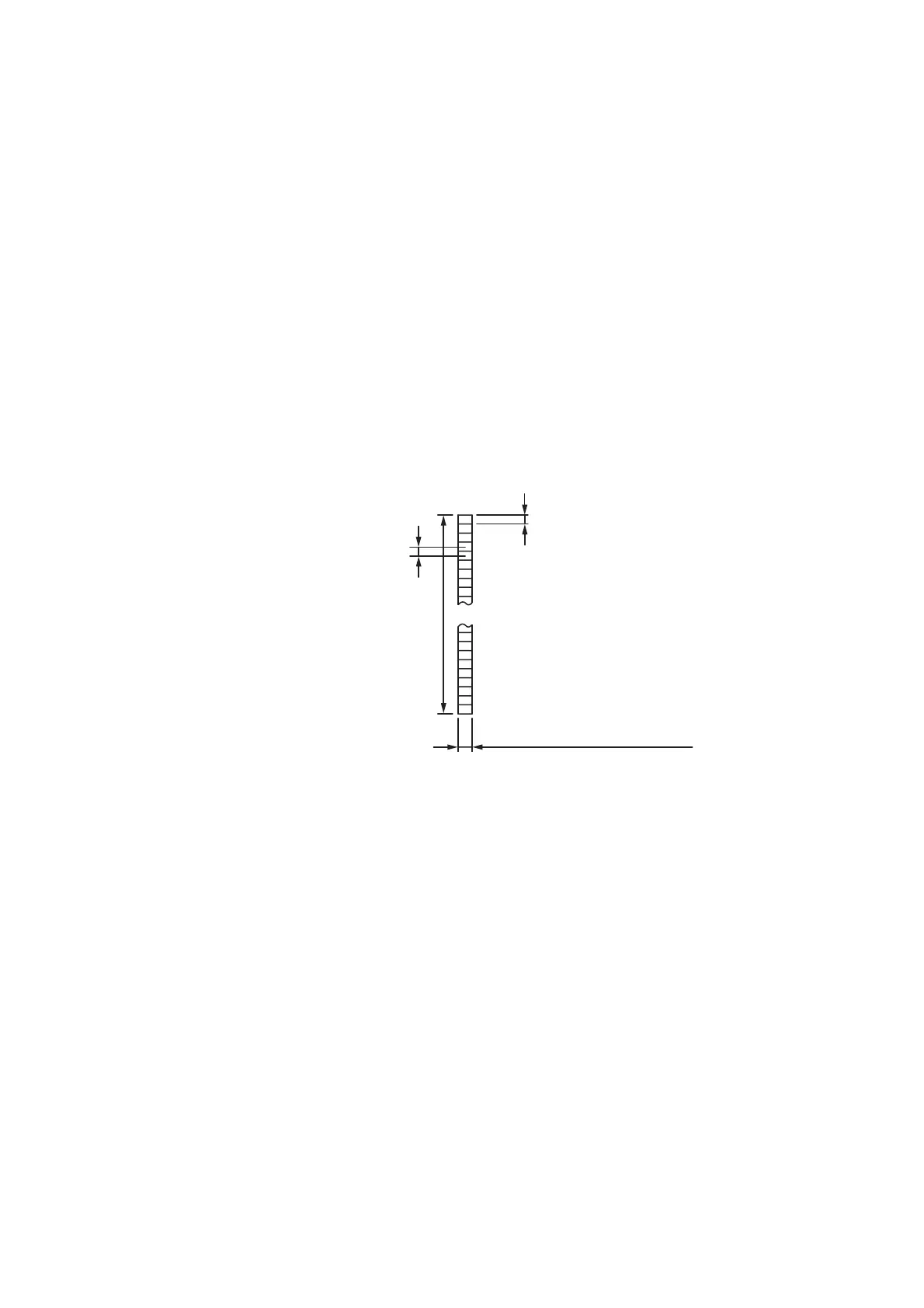

This machine adopts direct thermal printing system. The thermal head consists of 448

pieces (TD-2020/2120N) or 672 pieces (TD-2130N) of heating elements arrayed in

vertical single row as shown in the Figure 2.1-1.

The dimension of each heating element is vertical length 0.11 (TD-2020/2120N) or 0.07

(TD-2130N) (0.125mm pitch (TD-2020/2120N) or 0.0847mm pitch (TD-2130N)) x

horizontal width 0.132mm (TD-2020/2120N) or 0.11mm (TD-2130N).

Figure 2.1-1 Heating Elements of Thermal Head

■ Printing Process

A thermal paper is pressed against the thermal head in the printing process by the

force comes from a nip between the cylindrical rubber platen and the thermal head.

At this timing, voltage is applied selectively to 448 or 672 pieces of heating elements

arrayed on the thermal head. By this voltage application, the heating elements

generate heat and the thermal tape develops dots by itself at heat sensing points.

After application of voltage the thermal paper is fed to the next printing position by the

platen (0.0847 or 0.125mm).

This printing cycle is repeated and characters and geometries are printed on the tape.

One time travel distance (0.0847 or 0.125mm) is shorter than the width of a heating

element (0.11 or 0.132mm), so that continuous printing cycle can print characters and

geometries on a tape by developing dots with no gap.

Length

TD-2020/2120N: 0.11mm

TD-2130N: 0.07mm

Pitch

TD-2020/2120N: 0.125mm

TD-2130N: 0.0847mm

TD-2020/2120N: 0.132mm

TD-2130N: 0.11mm

Loading...

Loading...