1 - 3

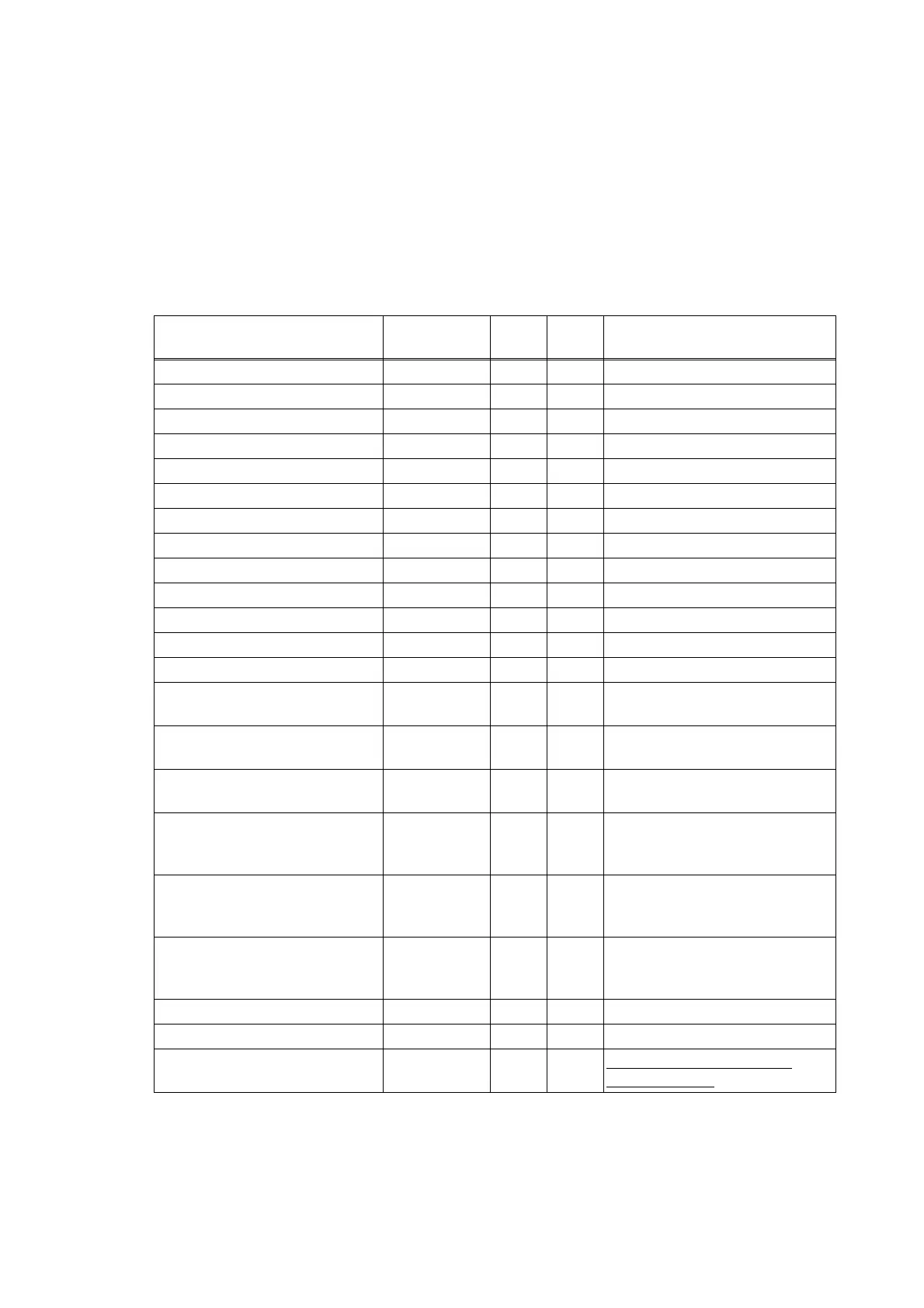

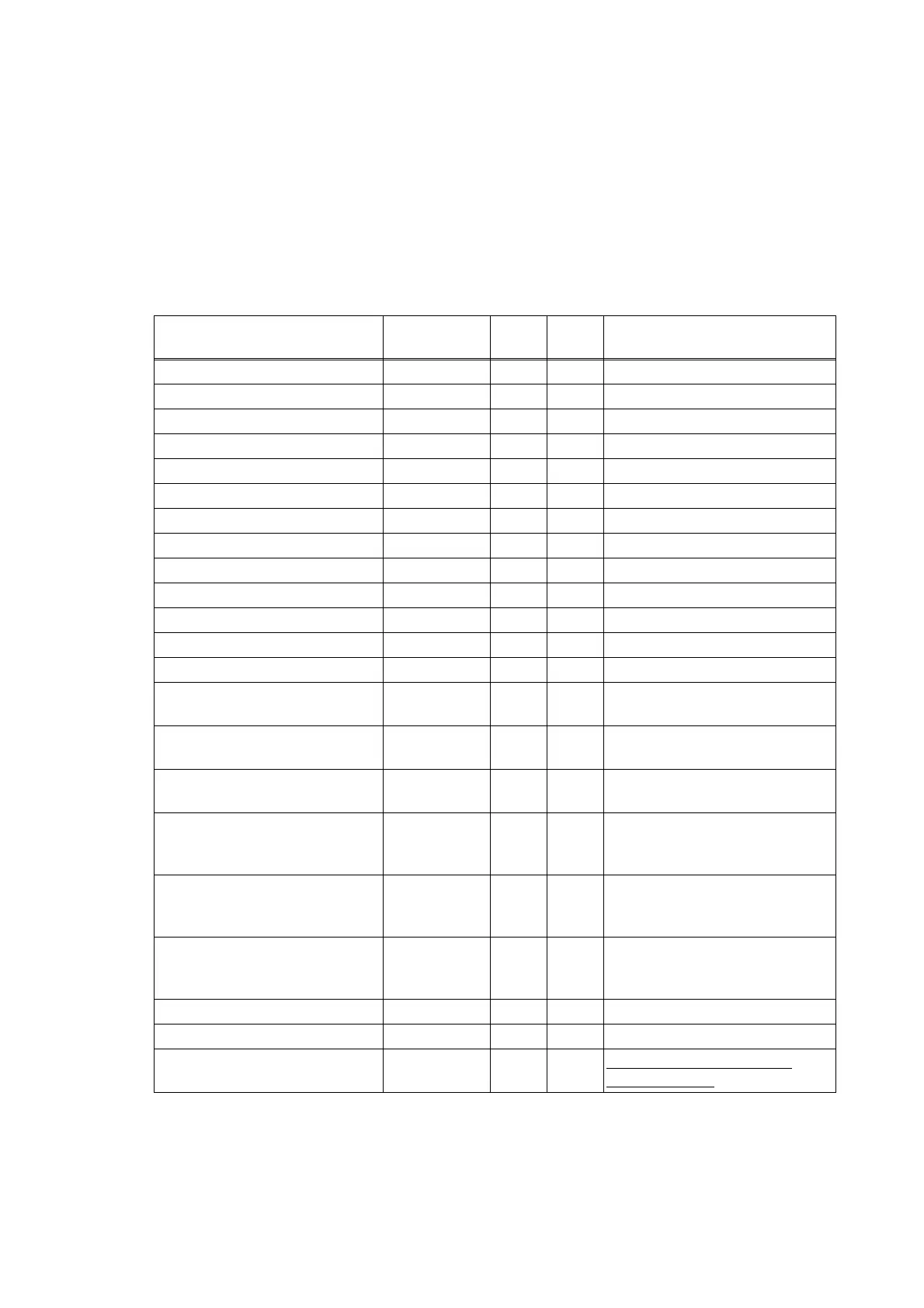

1.2.2 Inspection Outline

When you start the tool and implement "Read serial no", the next available inspection, "Write

default eeprom data", becomes operable after completion of the inspection. All the listed

inspections will be completed by operating in descending order. Inspections after "Check

adaptor AD" are optional. They can be omitted when the operation has been already checked or

the inspection is unnecessary. However, be sure to implement "Write serial no" as the last item.

Note : Serial number will not be written into the machine unless "Write serial no" is completed.

Inspection list ("

O

": valid "

-

": invalid)

*1 Only for TD-2130N. This setting applies only to HC models.

Operation procedures for each inspection item are explained in the following pages.

Procedures can be different between TD-2000 and TD-2100N. Follow the instructions for each

model explained hereafter.

Name of inspection

Communication

I/F

2000 2100N Note

Read serial no USB

OO

Check MAC address USB

-

O

Write default eeprom data USB

OO

Write media information USB

OO

Write product info USB

OO

Write mass storage info USB

OO

Write pincode and localname USB

-

O

Adjust transmission sensor USB

OO

Adjust reflecting sensor USB

OO

Reboot printer USB

OO

Print test(Label) USB

OO

Check adaptor AD USB

OO

Check USB host USB

-

O

Check connect TDU USB

-

O

Optional touch panel display unit

connection is required.

Check peel sensor (Paper none) USB

-

O

Optional peeler connection is

required.

Check peel sensor (Paper on) USB

-

O

Optional peeler connection is

required.

Check battery AD USB

-

O

Optional battery base unit and

battery are required for power

supply.

Check holder adaptor AD USB

-

O

Optional battery base unit and

adapter are required for power

supply.

Check battery charge USB

-

O

Optional battery base unit,

battery and adapter are required

for power supply.

Check LED USB

OO

Write smart info USB

-

*1

Write serial no RS-232C

OO

Always operate as the last

inspection item.

Loading...

Loading...