1 - 1

APPENDIX 1 SERVICEMAN SOFTWARE TOOL

1.1 Introduction

1.1.1 Software Tools

In addition to the primary serviceman tool, the buffer analysis tool is also equipped for TD-

20220/2120N/2130N. Implement each tool as usage.

• Serviceman tool

This tool is used to change EEPROM setting and check functions after machine repair or

PCB replacement. Serviceman tool does not perform inspection for optional products. Note

that separate inspections are required as needed.

• Buffer analysis tool

This tool serves to analyze commands and other data received by the machine.

1.1.2 Items Required for the Inspection

To use serviceman tool, the following items are required:

Items required for the inspection (1)

Items required for the inspection (2)

Note : Optional touch panel display unit, optional battery base unit, and optional peeler are

used to check performance of the connector on the machine side. Connect to the

machine with no optional products attached, and check the performance. Even the

machine has been equipped with optional products at the time of service, you can still

operate inspection.

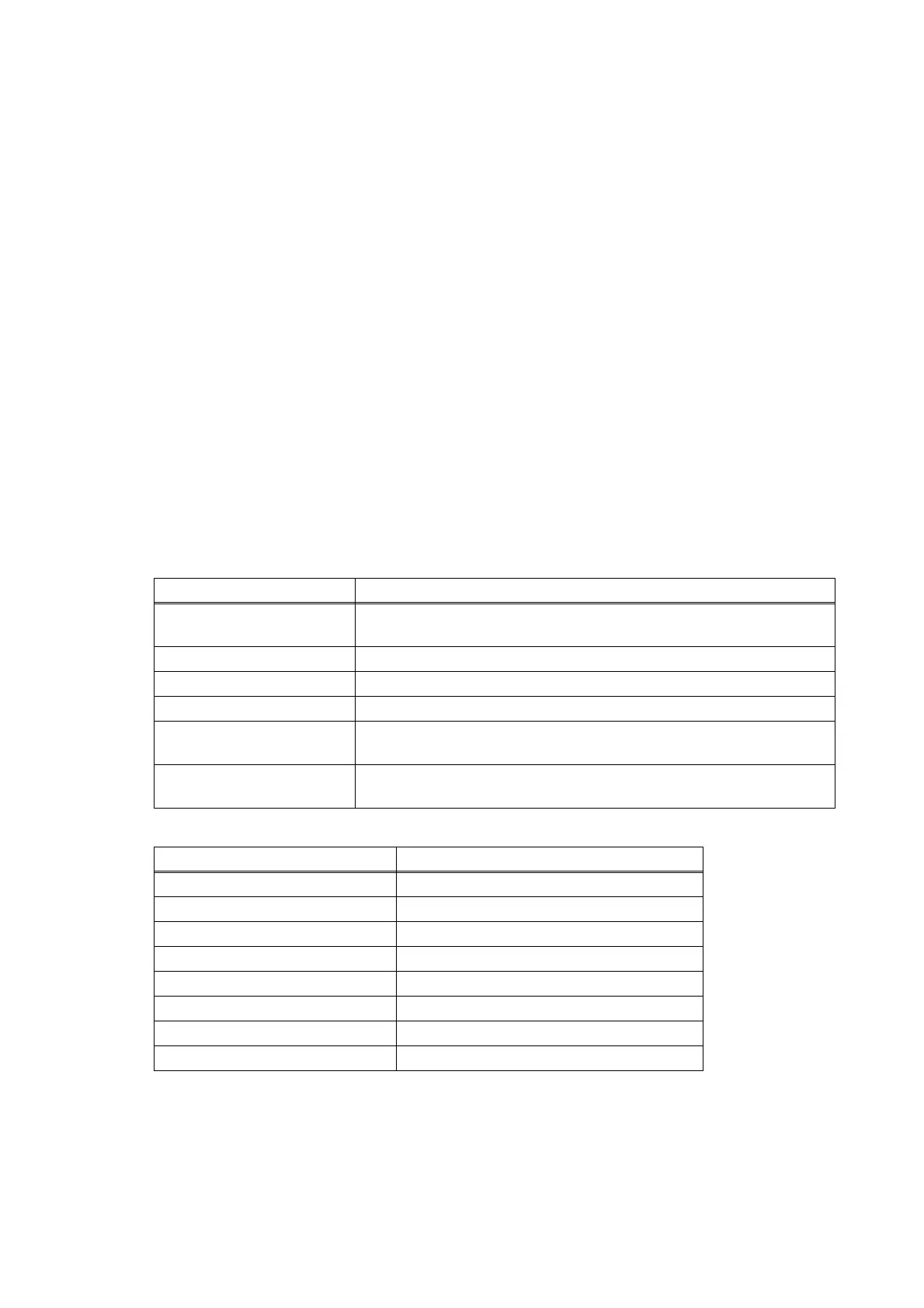

Item Remark

PC Supported OS are Windows XP and Windows 7. A COM port is

required.

USB cable The one included in TD-2000 / 2100N package or equivalent.

RS-232C cable D-Sub9pin (Interlink supported) female, female

AC adapter The one included in TD-2000 / 2100N package.

USB bar code reader Refer to "8. Connecting a bar code reader" in the TD series USER'S

GUID to check operation of the bar code reader beforehand.

Media for reflection sensor

adjustment

Use DK label roll (62x100mm).

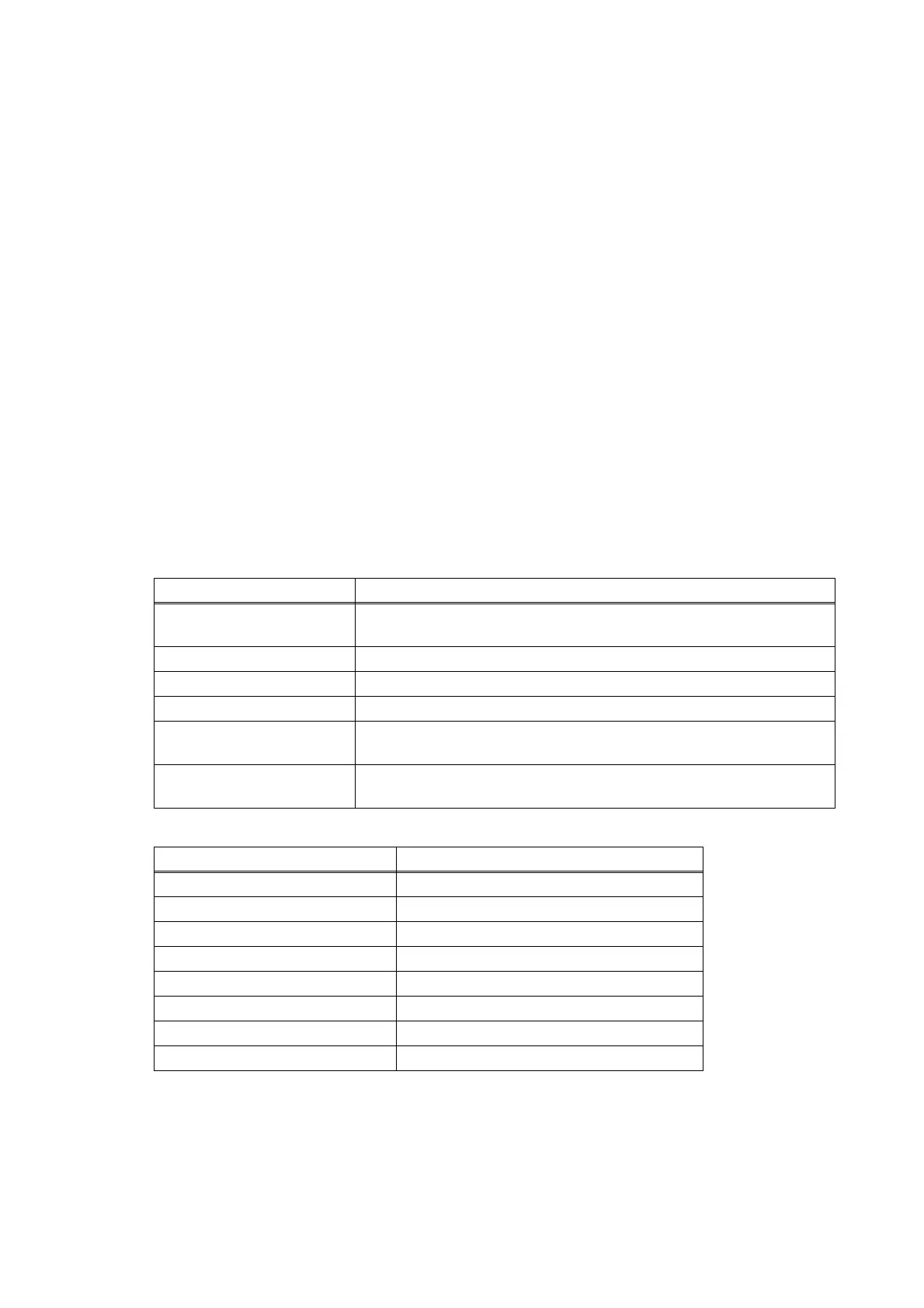

Item Item code

Li-ion rechargeable battery LI-ION BATTERY PA-BT-4000LI

80GS OJI roll ASSY 80GS OJI ROLL ASSY

RDU F59X102 1 ASSY RD-U F59X102 ASSY

RDJ51X26N roll ASSY RD-S05J1 P51X26 N ROLL ASSY

RS-232C cable (adapter) PA-SCA-001

Optional touch panel display unit PA-TDU-001

Optional battery base unit PA-BB-001

Optional peeler PA-LP-001

Loading...

Loading...