2-12 2002 Buell S3T: Chassis

HOME

CHECKING CAST RIM RUNOUT 2.7

GENERAL

Check wheels for lateral and radial runout before installing a

new tire.

Rim Lateral Runout

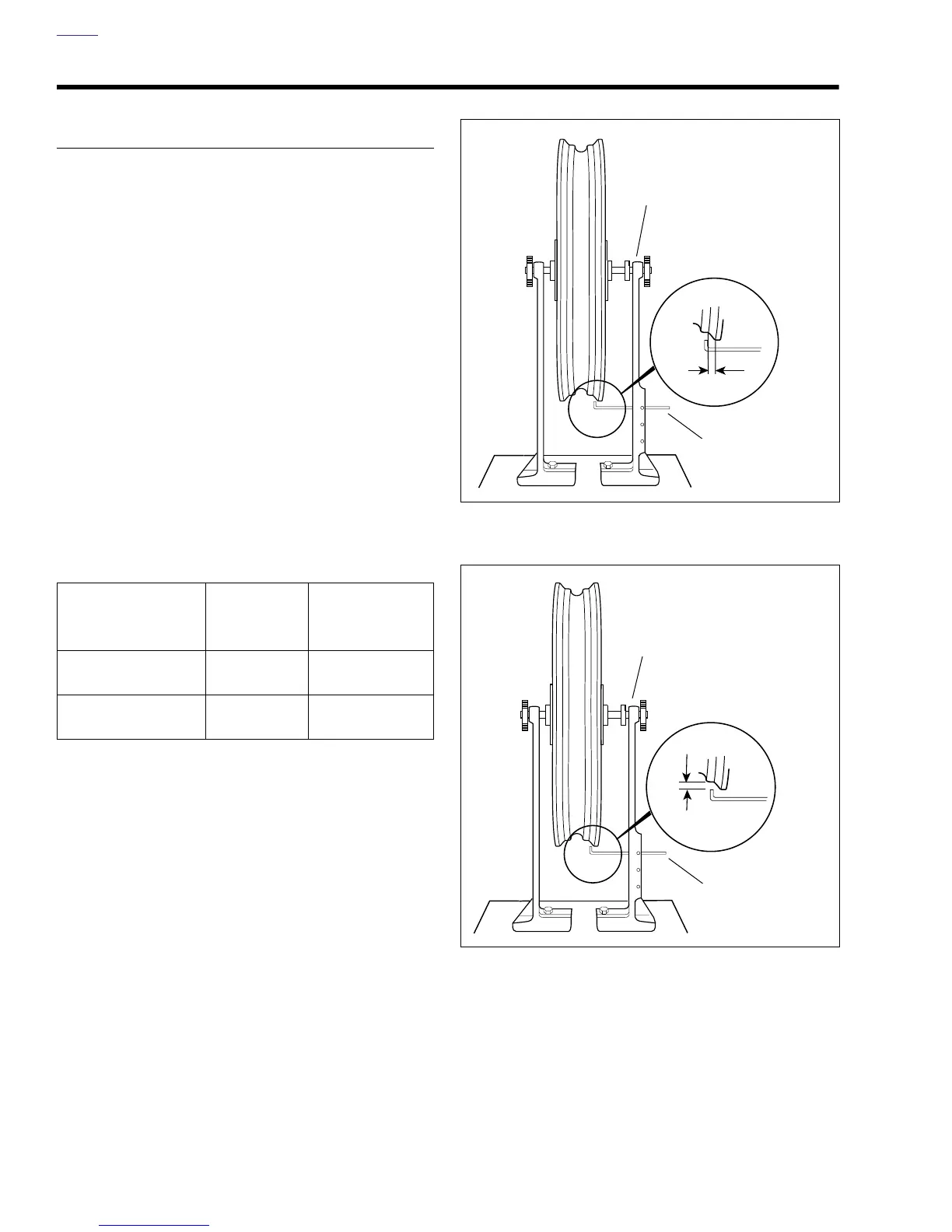

1. See Figure 2-9. Install truing arbor in wheel hub and

place wheel in WHEEL TRUING AND BALANCING

STAND (Part No. HD-99500-80).

2. Tighten arbor nuts so hub will turn on its bearings.

3. Check rim lateral runout by placing a gauge rod or dial

indicator near the rim bead. Replace wheel if lateral

runout exceeds specification shown in Ta ble 2-4.

Rim Radial Runout

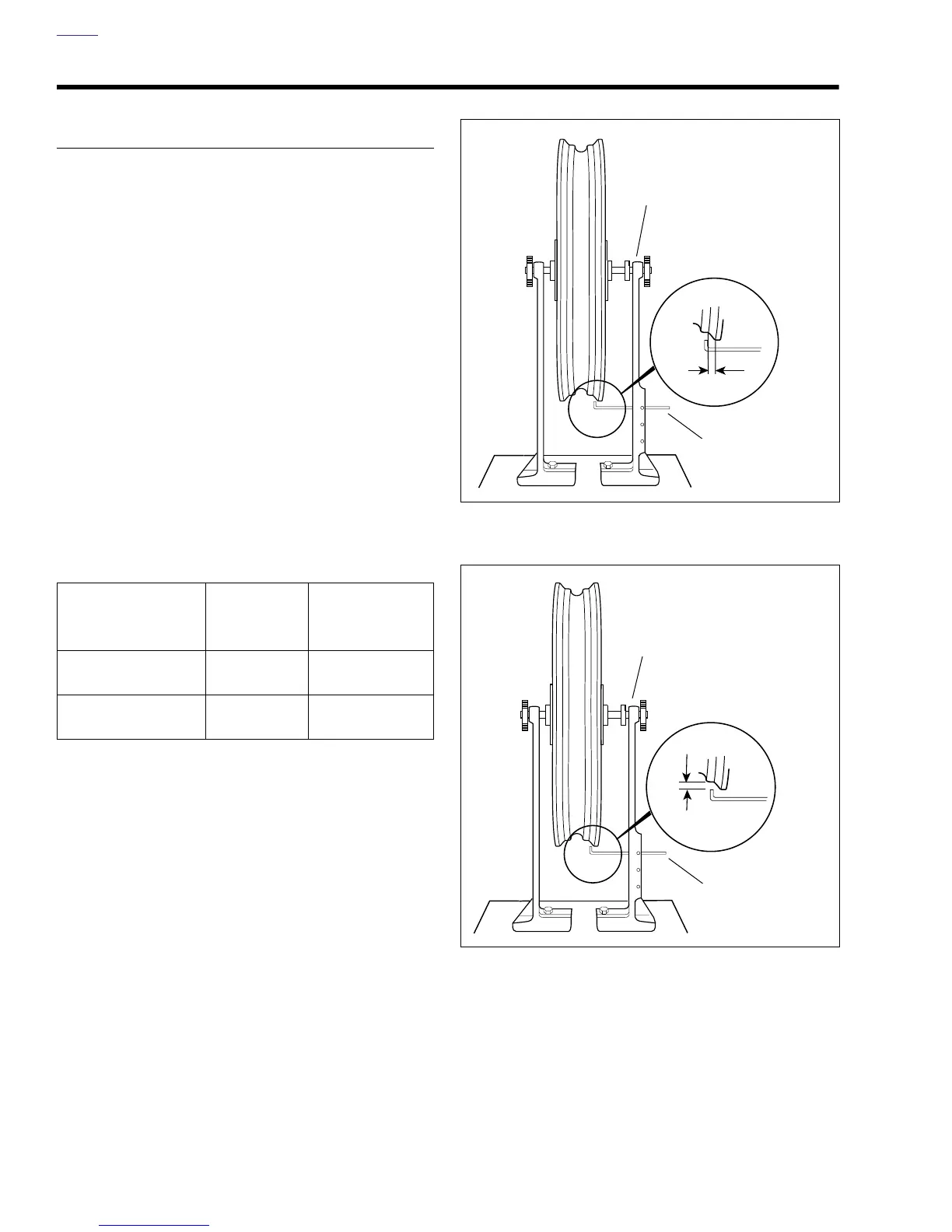

1. See Figure 2-10. Install truing arbor in wheel hub and

place wheel in WHEEL TRUING AND BALANCING

STAND (Part No. HD-99500-80).

2. Tighten arbor nuts so hub will turn on its bearings.

3. Check radial runout as shown. Replace wheel if runout

exceeds specification shown in Tabl e 2-4.

Table 2-4. Wheel Runout

WHEEL TYPE

MAXIMUM

LATERAL

RUNOUT

MAXIMUM

RADIAL

RUNOUT

Cast 0.040 in.

(1.02 mm)

0.030 in.

(0.76 mm)

Aluminum P/M 0.020 in.

(0.51 mm)

0.020 in.

(0.51 mm)

Figure 2-9. Checking Cast Rim Lateral Runout

Figure 2-10. Checking Cast Rim Radial Runout

f1378x2x

Gauge rod

Wheel Truing and Balancing

Stand (Part No. HD-99500-80)

f1379x2x

Gauge rod

Wheel Truing and Balancing

Stand (Part No. HD-99500-80)

Loading...

Loading...