2002 Buell S3T: Chassis 2-23

HOME

c. Install pad hanger pin (1) (metric). Tighten to 11-

14.5 ft-lbs (15-20 Nm).

d. See Figure 2-25. Install pin plug (4). Tighten to 1.5-

2.1 ft-lbs (2-3 Nm).

11WARNING1WARNING

Use only copper crush banjo washers (See Parts Catalog

for Part No.) with D.O.T. 4 brake fluid. Earlier silver banjo

washers are not compatible with D.O.T. 4 fluid and will

not seal properly over time. Failure to comply may

adversely affect braking ability and lead to brake failure

which could result in death or serious injury.

11WARNING1WARNING

Any leak in brake system will adversely affect brake

operation. To avoid leakage, verify that gaskets, banjo

bolt, hydraulic brake line and caliper bore are completely

clean. Failure to comply could result in death or serious

injury.

4. Connect brake line (1) to caliper using two new banjo

washers (3) and banjo bolt (2) (metric). Tighten to 16-20

ft-lbs (22-27 Nm).

CAUTION

Cover painted surfaces and right handlebar switches and

use care when removing brake reservoir cover and add-

ing D.O.T. 4 brake fluid. Spilling D.O.T. 4 brake fluid on

painted surfaces will result in cosmetic damage. Spilling

brake fluid on switches may render them inoperative.

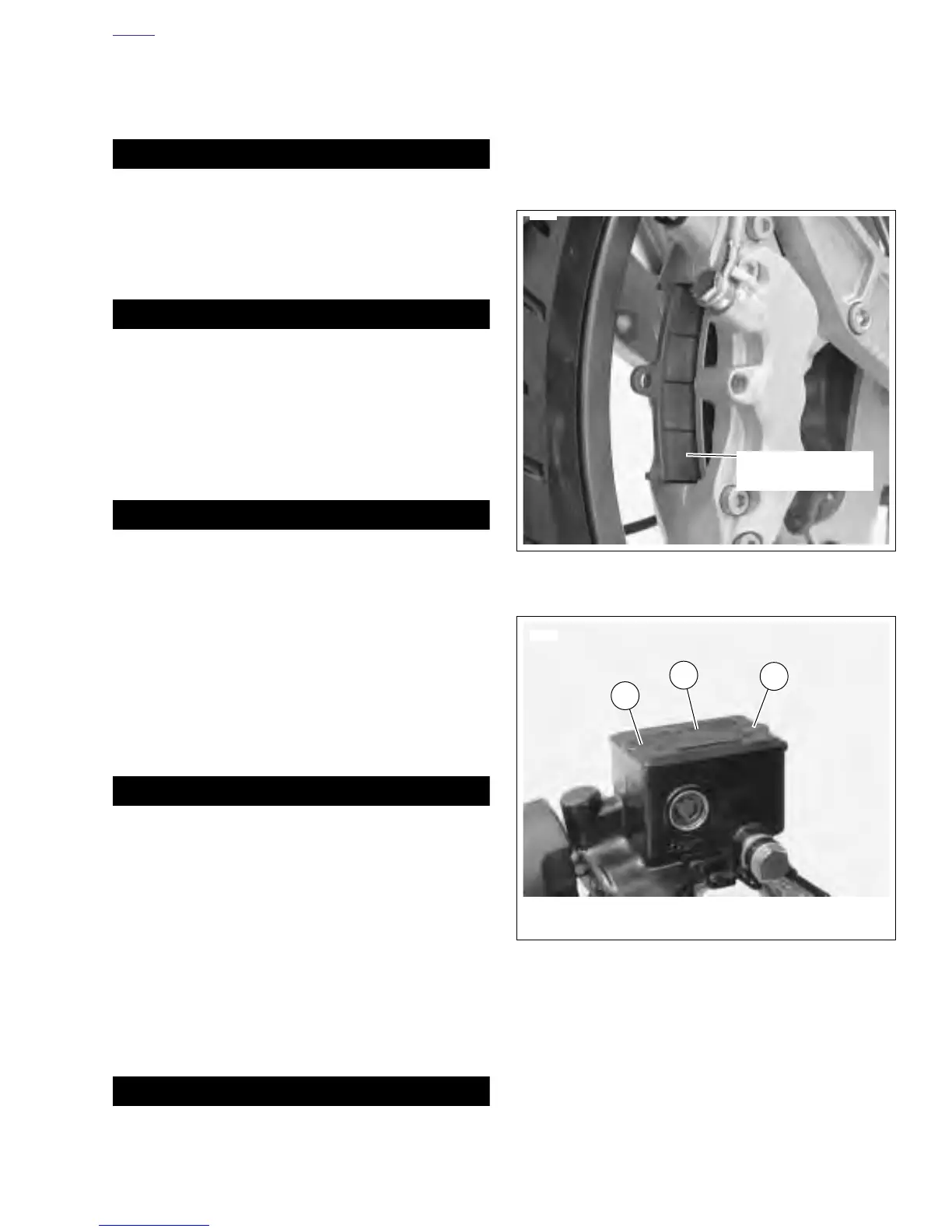

5. See Figure 2-30. Remove both master cylinder cover

screws (2). Remove master cylinder cover (1) and gas-

ket.

6. With the master cylinder in a level position, verify that the

brake fluid level is 1/8 in. (3.2 mm) from molded boss

inside reservoir. Add D.O.T. 4 BRAKE FLUID if neces-

sary.

11WARNING1WARNING

Always verify proper operation of relief port (see Step 7).

A plugged or covered relief port can cause brake drag or

lockup, which may cause loss of vehicle control which

could result in death or serious injury.

7. Verify proper operation of the master cylinder relief port.

Actuate the brake lever with the reservoir cover removed.

A slight spurt of fluid will break the surface if all internal

components are working properly.

8. Install master cylinder cover and cover gasket with two

screws (1). Tighten to 9-13 in-lbs (1-2 Nm).

9. Depress front brake lever several times to set brake pads

to proper operating position within caliper. Bleed brake

system. See 1.5 BRAKES.

11WARNING1WARNING

Check for proper brake lamp operation before riding

motorcycle (see Step 10). Visibility is a major concern for

motorcyclists. Failure to have proper brake lamp opera-

tion could result in death or serious injury.

10. Turn ignition key switch to IGN. Apply brake hand lever to

test brake lamp operation. Turn ignition key switch to

LOCK.

NOTE

Avoid making hard stops for the first 100 miles (160 km) to

allow new brake pads to “wear in” properly with the brake

rotor.

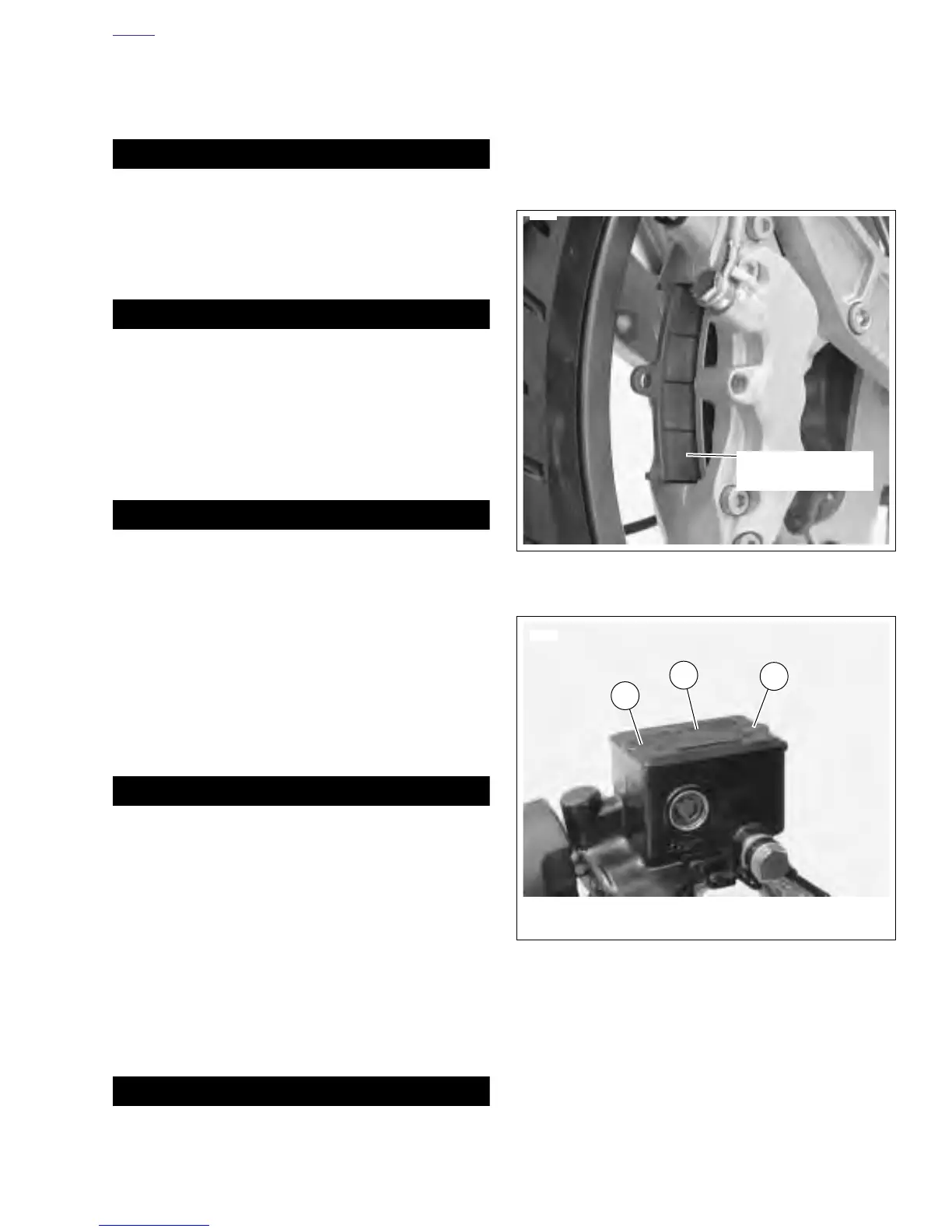

Figure 2-29. Installing Brake Pads

Figure 2-30. Master Cylinder Cover

6545

This surface

against brake rotor

6069a

1. Master Cylinder Cover

2. Screws (2)

2

2

1

Loading...

Loading...