Flow Rate and Fluid Property Calculations

The Scanner 3100 calculates ow rates and uid properties for natural gas and liquid ow in accordance with the fol-

lowing industry standards. The calculations compensate for the effects of pressure, temperature, and uid composition to

determine mass and volume at specied base conditions. The uid corrections typically require conguration of inputs

including static pressure and temperature. The ow calculation requires conguration of differential pressure or pulse

(frequency) inputs.

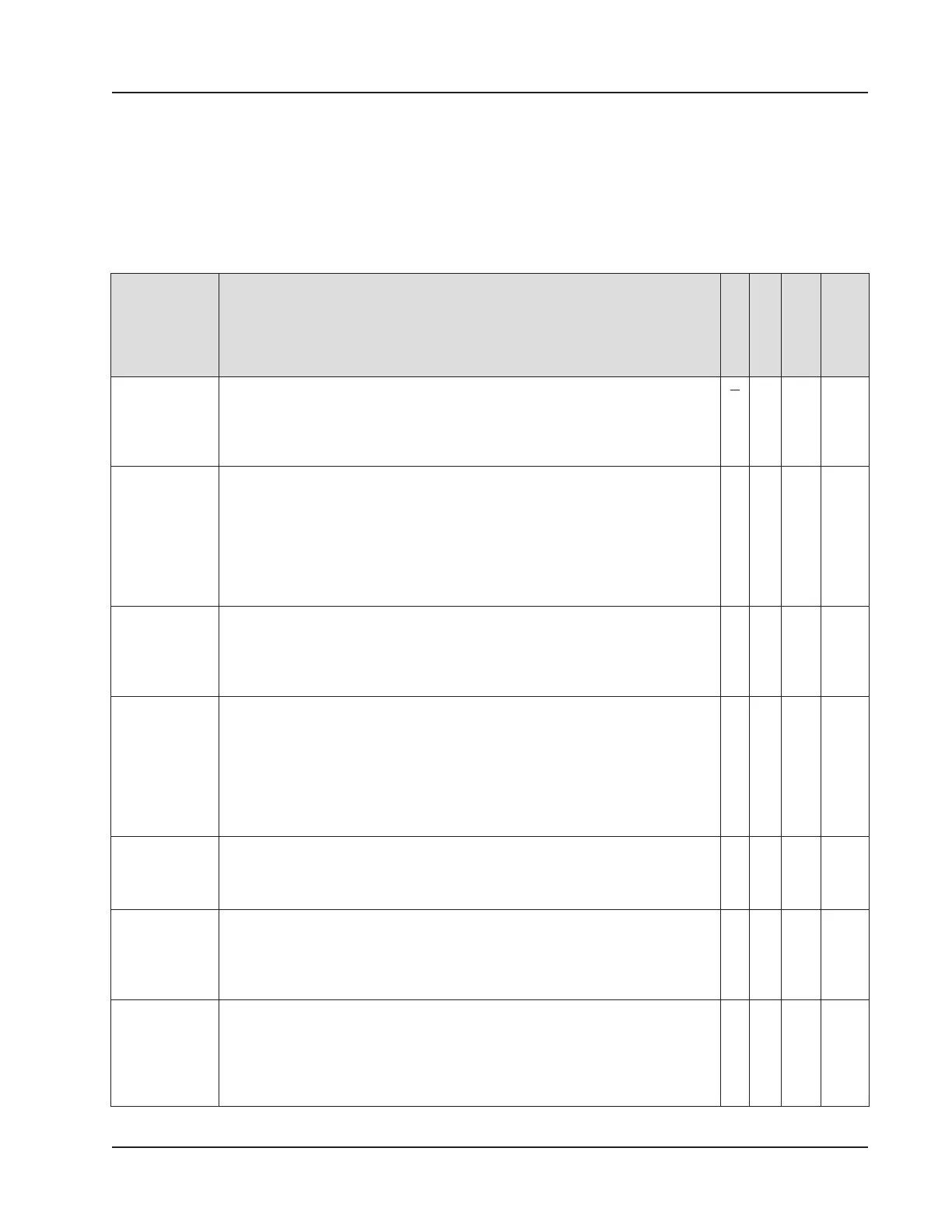

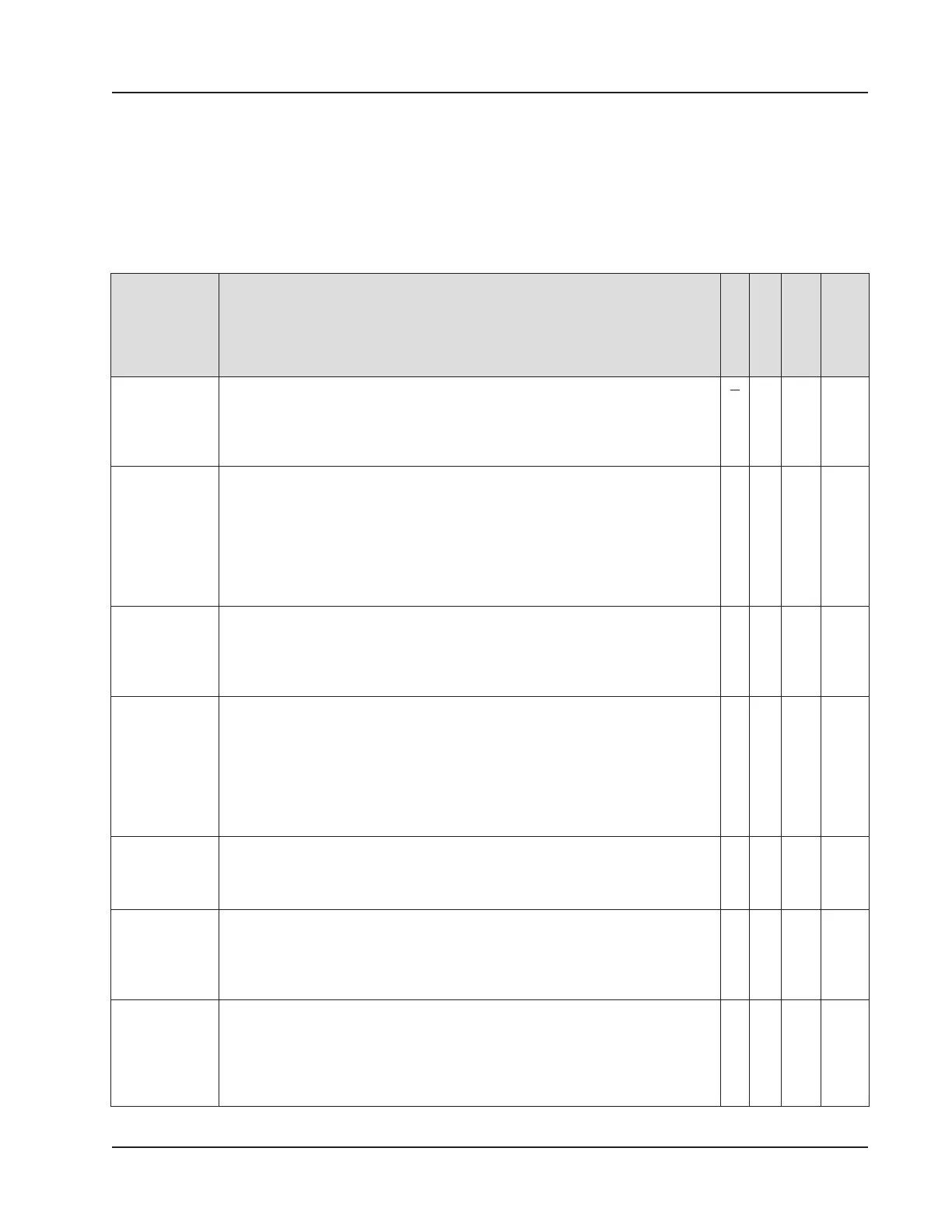

Table 1.4—Flow Rate Standards

Standard Description

Orice

NuFlo Cone

Linear Pulse

Output

Venturi

AGA 3

(1992)

The Scanner 3100 supports the orice metering calculations described in AGA

Report No. 3 (1992). This meter covers pipe sizes of nominal 2-in. and larger;

there is no stated maximum limit, but the largest size listed in the standard is

nominal 36 inch. Beta ratio must lie between 0.1 and 0.75. The AGA 3 orice

meter can be used to measure natural gas and liquids.

♦

AGA 3

(2012)

The Scanner 3100 supports the orice metering calculations described in

AGA Report No. 3 (2012). The AGA 3 orice meter covers pipe sizes of

nominal 2-in. and larger; there is no stated maximum limit, but the largest size

listed in the standard is nominal 36-in. Beta ratio must lie between 0.1 and

0.75. The 2012 report offers an improved expansion factor correction and is

recommended for use except where contractual or regulatory requirements

specify the 1992 standard. The AGA 3 orice meter can be used to measure

natural gas and liquids.

♦

ISO 5167-2

(2003)

ISO 5167-2 describes the measurement of natural gas and liquids with an

orice meter using pipe sizes of nominal 50 mm (2 in.) to a maximum of 1000

mm (39 in.). Beta ratio must lie between 0.1 and 0.75. In ASME MFC-3M

(2004), the ISO-5167 orice ow calculation was adopted without modication.

The ISO orice meter can be used to measure natural gas and liquids.

♦

ISO 5167-4

(2003)

ISO 5167-4 provides information for calculating ow rates with Venturi tubes.

It is applicable only to Venturi tubes in which the ow remains subsonic

throughout the measuring section and where the uid can be considered

as single-phase. In addition, each of these devices can only be used within

specied limits of pipe size, roughness, diameter ratio and Reynolds number.

ISO 5167 4 is not applicable to the measurement of pulsating ow. It does not

cover the use of Venturi tubes in pipes sized less than 50 mm or more than

1200 mm, or for where the pipe Reynolds numbers are below 20000.

♦

ASME

MFC-14M

(2003)

For low ow applications, the Scanner 3100 supports the small bore orice

described in ASME MFC-14M for use with nominal 1/2-in. to 1-1/2-in. pipe

sizes. Beta ratio must lie between 0.1 and 0.75. The ASME small bore orice

meter can be used to measure natural gas and liquids.

♦

AGA 7 (2006) AGA 7 provides the measurement standards used to calculate natural gas

ow rates from linear pulse output meters, including turbine meters, vortex

shedding meters, pulser-equipped positive displacement (PD) meters, Coriolis

meters having volumetric pulse output, and other types. Linear pulse output

meters can be used to measure natural gas and liquids.

♦

Miller

Handbook,

Third Ed.

Richard Miller’s Flow Measurement Engineering Handbook provides denitive

information on selecting, sizing, and performing pipe-ow-rate calculations,

using ISO and ANSI standards in both SI and US equivalents. This reference

also presents physical property data, support material for important uid

properties, accuracy estimation and installation requirements for all commonly

used ow meters.

♦

23

Scanner 3100 EFM Section 1

Loading...

Loading...