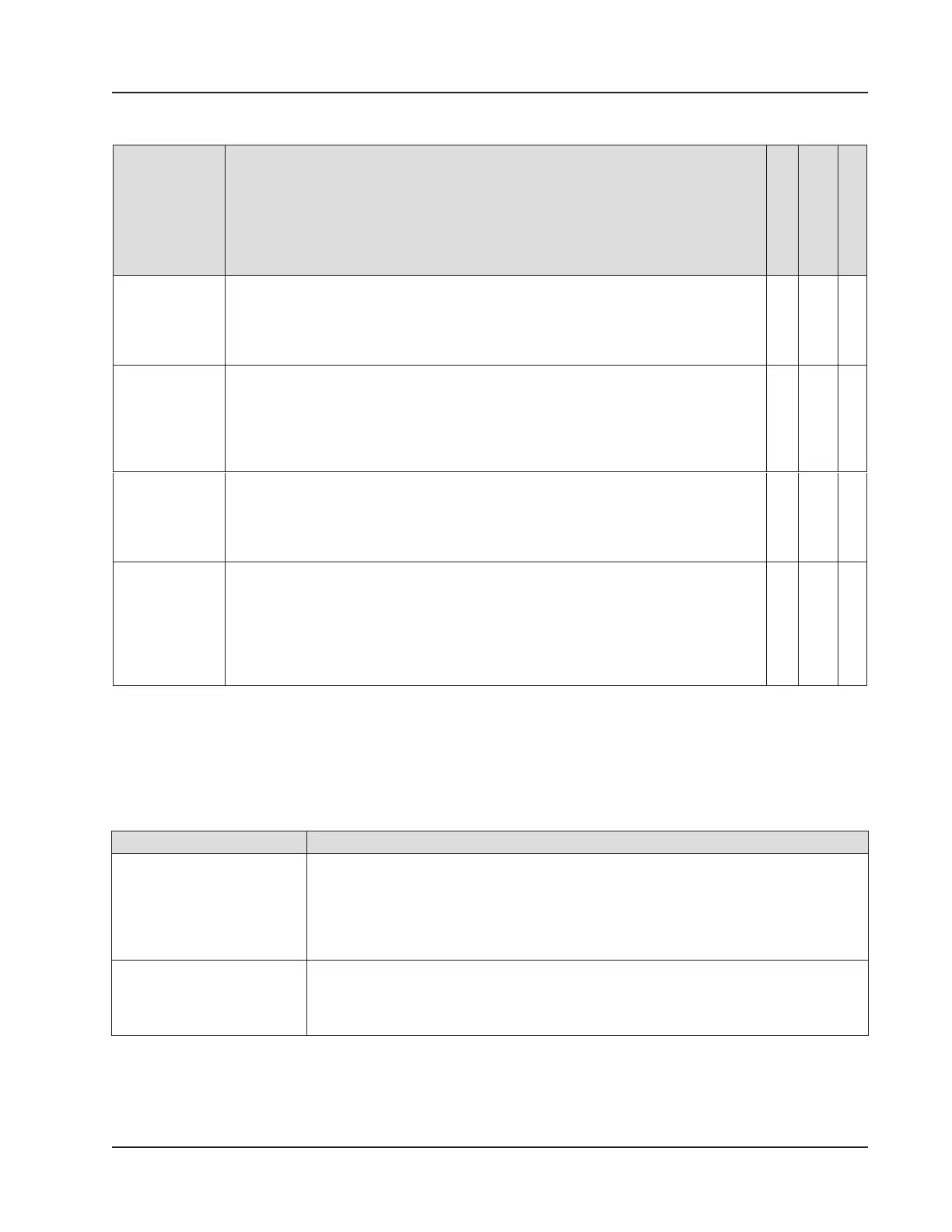

Table 1.5—Fluid Property and Energy Flow Calculations

Standard Description

Natural Gas

Hydrocarbon

Liquid

Steam

GPA 2145

(2008)

GPA 2145 is a compilation of numerical values for the parafn hydrocarbons and

other compounds occurring in natural gas and natural gas liquids as well as for a few

other compounds of interest to the industry. GPA 2145 supports an intermediate cal-

culation and therefore is not a standard uid property selection in the Scanner 3100

web interface.

♦

ISO 6976

(1995)

ISO 6976 species methods for the calculation of the superior caloric value and the

inferior caloric value, density, relative density and Wobbe index of dry natural gas

and other combustible gaseous fuels, when the composition of the gas by mole frac-

tion is known. A simplied version of the AGA 5 calculation, ISO 6976 supports an

intermediate calculation and therefore is not a standard uid property selection in the

Scanner 3100 web interface.

♦

IAPWS-IF97,

Saturated

Steam

IAPWS Industrial Formulation 1997 for the Thermodynamic Properties of Water and

Steam. This calculation should be used when the steam is assumed to be at the

saturation temperature at a given owing pressure. Only a pressure input is required.

Providing a steam quality measurement will yield an estimated liquid owrate and

produce accumulations for vapor and liquid water.

♦

IAPWS-IF97,

All Regions

IAPWS Industrial Formulation 1997 for the Thermodynamic Properties of Water and

Steam. This calculation should be used when measuring in regions off the saturation

line operating conditions and when the water is liquid or super-heated. A pressure

input and a temperature input are required. From the owing condition inputs, the

operating region of the water is detected: liquid water (Region 1), dry steam (Region

2), critical range (Region 3), and saturated steam (Region 4). All regions except liquid

water are accumulated as vapor.

♦

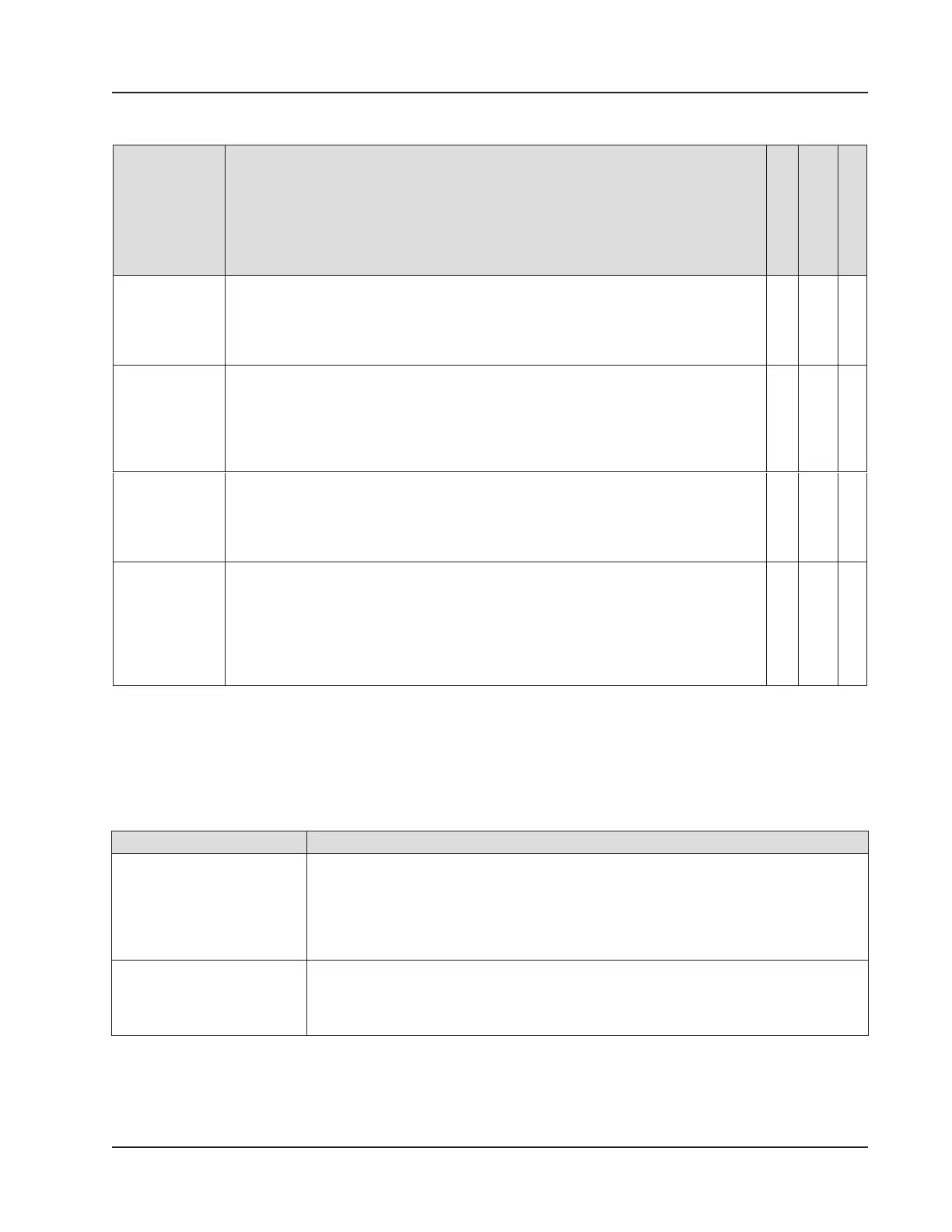

Flow Correction Factors

The Scanner 3100 measures compensated petroleum liquid ow using an orice or cone ow meter. For accuracy, these

measurements often include a correction factor to compensate for the effect of gas or water on volume, or changes in

calibration. Table 1.6 describes the correction factors congurable in the Scanner 3100 web interface.

Table 1.6—Flow Correction Factors

Flow Correction Factor Description

Multipoint Meter Factor

Correction (for Gas and

Liquid)

The multipoint meter factor calibration method allows users to compensate for

variations between calibrations without changing the meter K-factor from the value

stamped on the meter at the factory. Meter factors are typically determined through

calibrations performed by third-party test laboratories. You can enter the appropriate

factor during calibration to account for any variation in the calibration curve over

Reynolds numbers.

Chisholm-Steven Orice

Meter Multiphase

Correction (for Steam)

The Chisholm-Steven correction method is used for over-reading prediction in wet

vapor ow conditions (multiphase) for water at the owing conditions along the

saturation line. When provided with a quality measurement, the vapor ow is corrected

and the estimated liquid ow is accumulated.

25

Scanner 3100 EFM Section 1

Loading...

Loading...