The following accessories are also recommended:

• 5-valve manifold for connecting process lines to the MVT

• RTD assembly for process temperature input on gas ow runs and compensated liquid ow runs

• Tubing and/or pipe for plumbing process connections

• Explosion-proof signal cable for remote turbine connections (stranded, shielded cable is recommended)

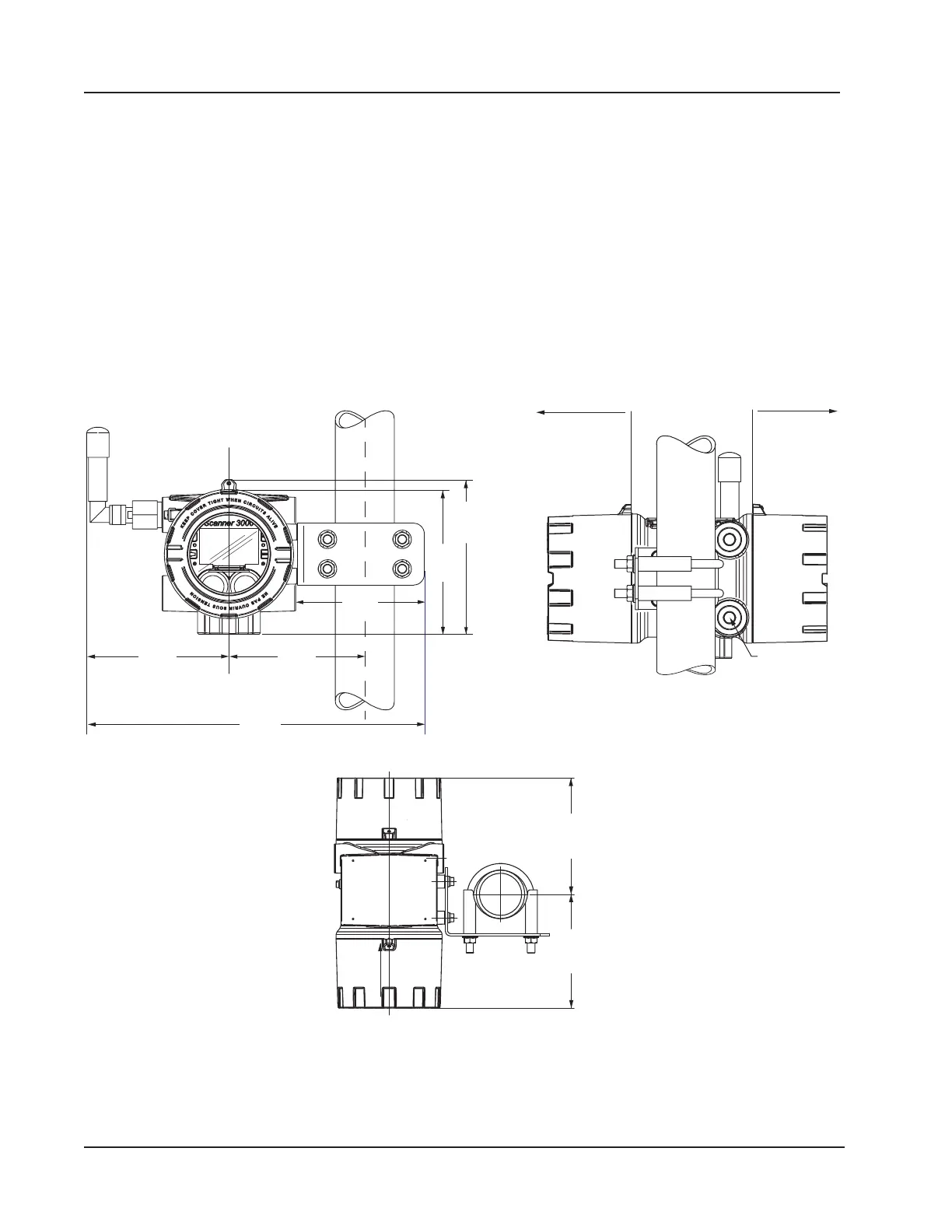

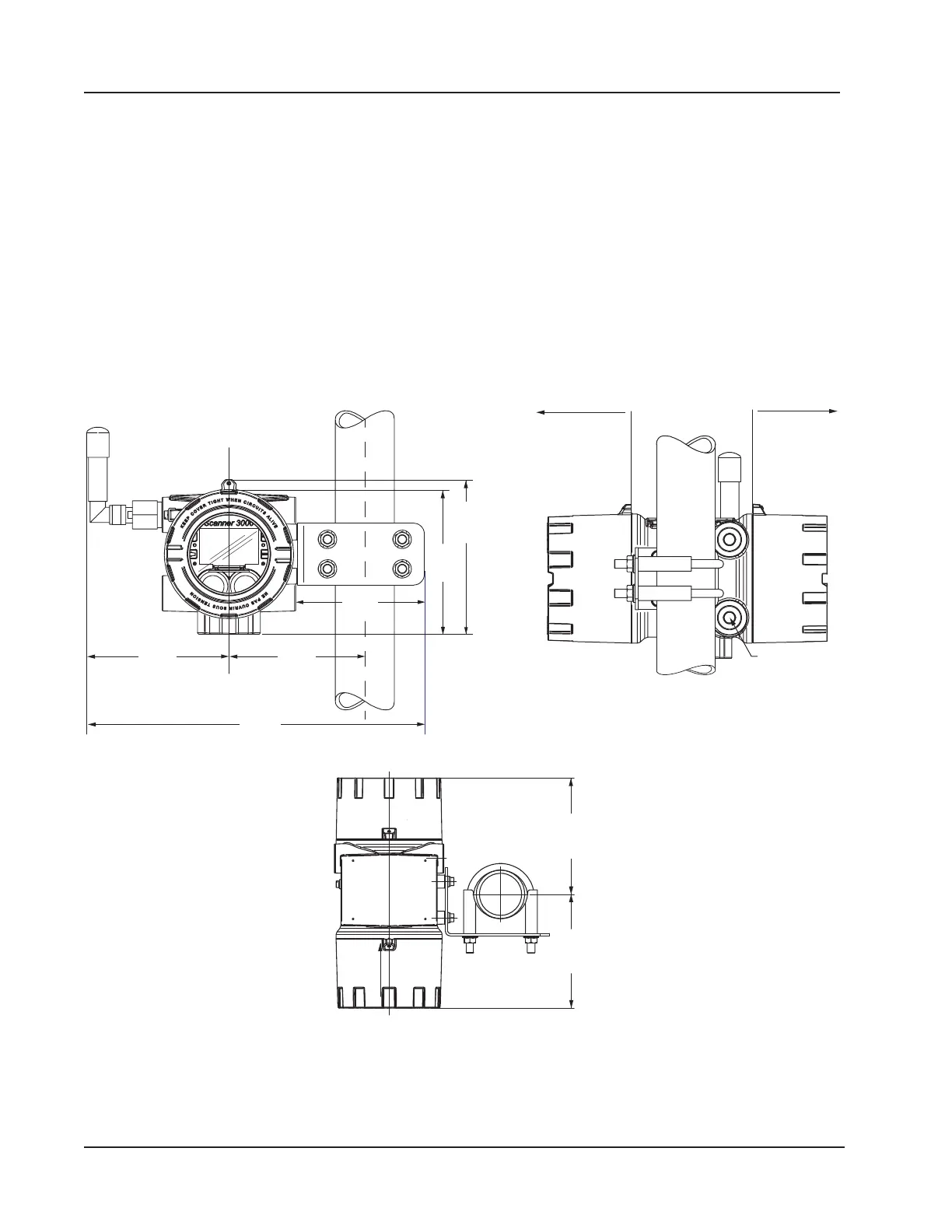

Pole-Mounting the Scanner 3100

The 2-in. pole mount hardware kit (Figure 2.2) is a convenient option for remote-mounting the Scanner 3100. The kit

consists of a stainless steel “L” mounting bracket with four mounting holes, two U-bolts, four nuts, and four 10-mm M6

screws.

CSA Requirement: When using standard cable, a conduit seal

must be installed within 6 in. (152.4 mm) of the Scanner.

5.72

(145.2)

5.46

(138.7)

13.58

(344.8)

5.80

(147.2)

6.20

(157.5)

8.5

(216)

clearance

required

for removing

batteries

5.0

(127)

clearance

required

for accessing

terminals

(front) (back)

straight

nipple/cable

radius up to

0.58 (14.73)

5.10

(129.7)

5.70

(144.8)

approx

5.58

(141.8)

approx

(front)

(back)

Figure 2.2—Scanner 3100 remote-mounted with a 2-in. pole mount kit; dimensions are shown in inches (mm)

30

Section 2 Scanner 3100 EFM

Loading...

Loading...