3.1.13-194

CS35 2013.04

3.1.13-194Electronic Control System - ME7

5. Inspect the camshaft position sensor

A. Use a diagnostic tool to clear the DTC.

B. Replace a intake camshaft position sensor that in

good condition, and fasten it with the standard

torque.

C. Start the engine and run it to the normal operating

temperature, then read DTC with diagnostic tool.

Does fault code still exist?

Y

Go to step 6.

N

Replace the camshaft position sensor.

Refer to: Camshaft Position Sensor (3.1.13

Electrical control System - ME7 Removal

and Installation).

6. Inspect the camshaft position sensor signal wheel

A. Inspect the camshaft position sensor signal wheel

installation location and tooth form.

Is the camshaft position sensor signal wheel nor-

mal?

Y

Go to step 7.

N

Replace or repair the camshaft position sensor sig-

nal wheel.

Refer to: Camshaft and Hydraulic Rocker

Component (3.1.2 Mechanical System,

Disassembly and Assembly).

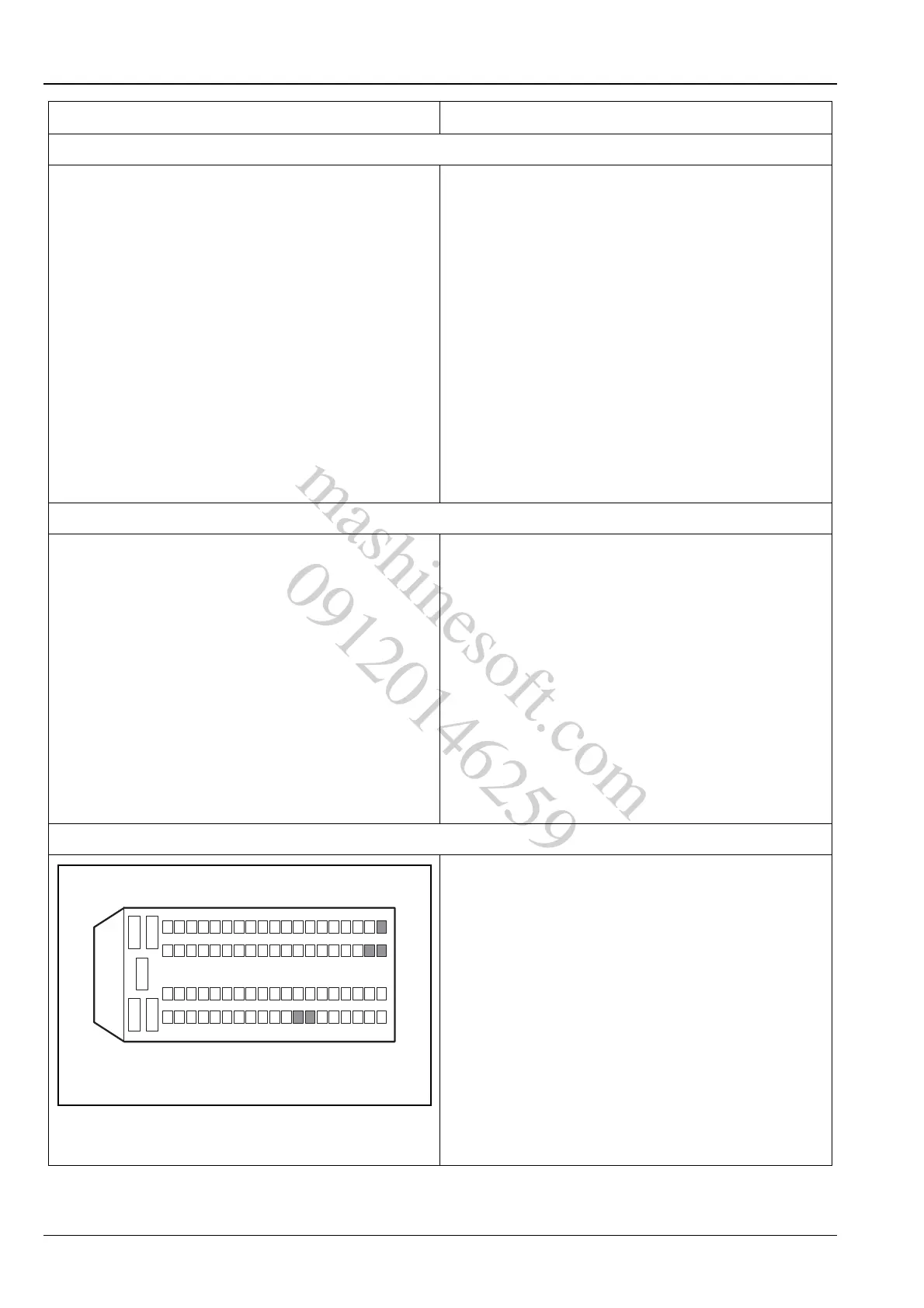

7. Inspect the ECM power supply circuit

A. Turn the ignition switch to position "LOCK".

B. Measure from the back of ECM wiring harness

connector E01.

C. Turn the ignition switch to "ON" position and use a

multimeter to measure the voltage between the

terminals 12, 13, 44, 45 and 63 of the ECM wiring

harness connector E01 and the power supply.

Standard Voltage Value: 11 ~ 14 V

Is the voltage normal?

Y

Go to step 8.

N

Repair and inspect the ECM power supply circuit.

Test Conditions Details/Results/Actions

12

3

45

624

2543

4462

63

13

12

45

81

E01

A3113031

mashinesoft.com

09120146259

Loading...

Loading...