9 Troubleshooting 125

5 Check the condition of the tested parts.

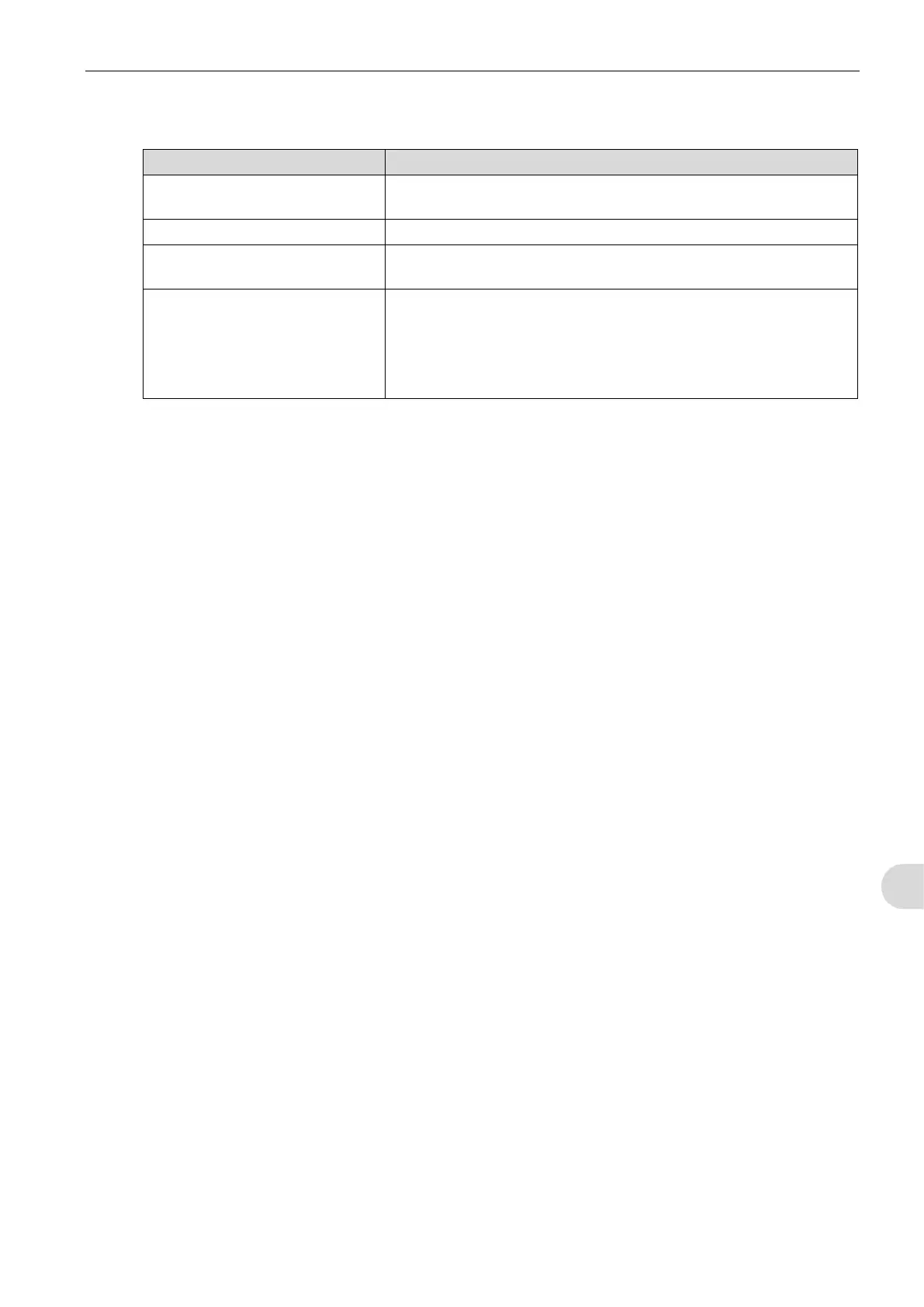

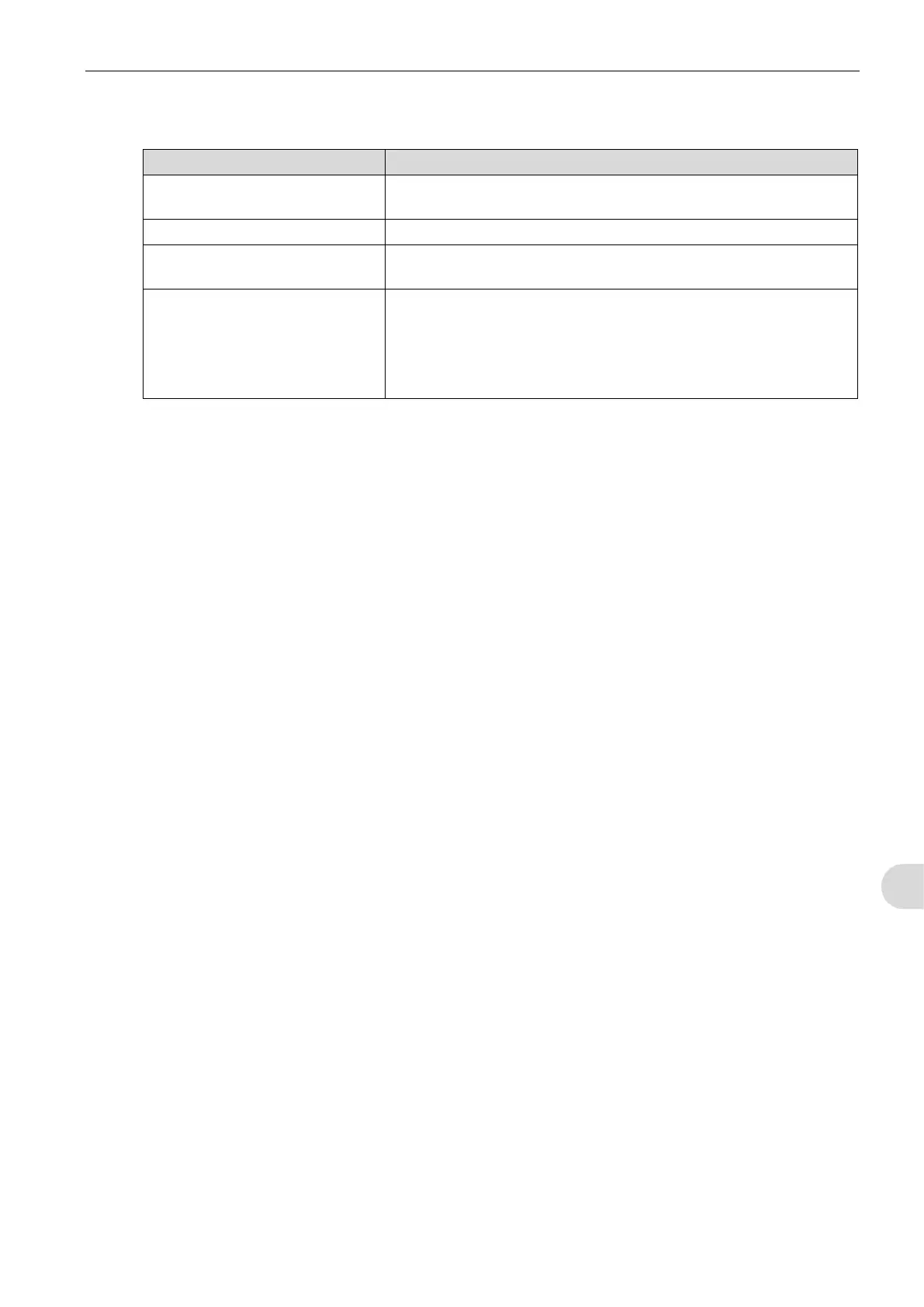

Probable Cause Treatment

Part temperature is higher or lower

than the ambient temperature.

Let the part temperature be ambient by adding a cooling/warming buffer in

the production line.

The tested parts are wet. Improve the drying process or add one if there isn't any.

The tested parts get deformed by

pressurization.

Add a stopper to prevent the deformation.

Leak due to the gas porosity or

internal leak

Look for leaks in the fittings by performing a bubble test applying soap

solution.

Redo the tubing if needed.

If no leak is confirmed, there may be internal leaks.

If there is a leak, re-evaluate the production process.

Loading...

Loading...