132 11 Reference

1

1

L

L

e

e

a

a

k

k

T

T

e

e

s

s

t

t

i

i

n

n

g

g

O

O

v

v

e

e

r

r

v

v

i

i

e

e

w

w

After a non-leaking reference part (MASTER) and a tested part (WORK) are pressurized simultaneously,

isolating the MASTER and WORK from the pressure source, and the differential pressure sensor (DPS)

measure the pressure drop resulting by leaks.

1.1 Stage Summary

Stages

Start After clamping and sealing a WORK, initiates a start signal.

Charge (CHG) Pressurizes or evacuates the WORK and the MASTER for testing.

Balance delay (DL2) Stops supply of test pressure. Waits for decrease in pressure changes

caused by valve operation.

Balance (BAL2) Isolates the WORK and the MASTER from each other to measure the

pressure difference between them. Detects large leaks.

Detection (DET) Detects small leaks. Drift compensation will be performed.

Air-blow, Exhaust and End

(BLW, EXH, END)

Transmits judgment signal, and exhausts air from inside the WORK and

MASTER from the exhaust port. Simultaneously, air-blow is performed to

clean inside the tester.

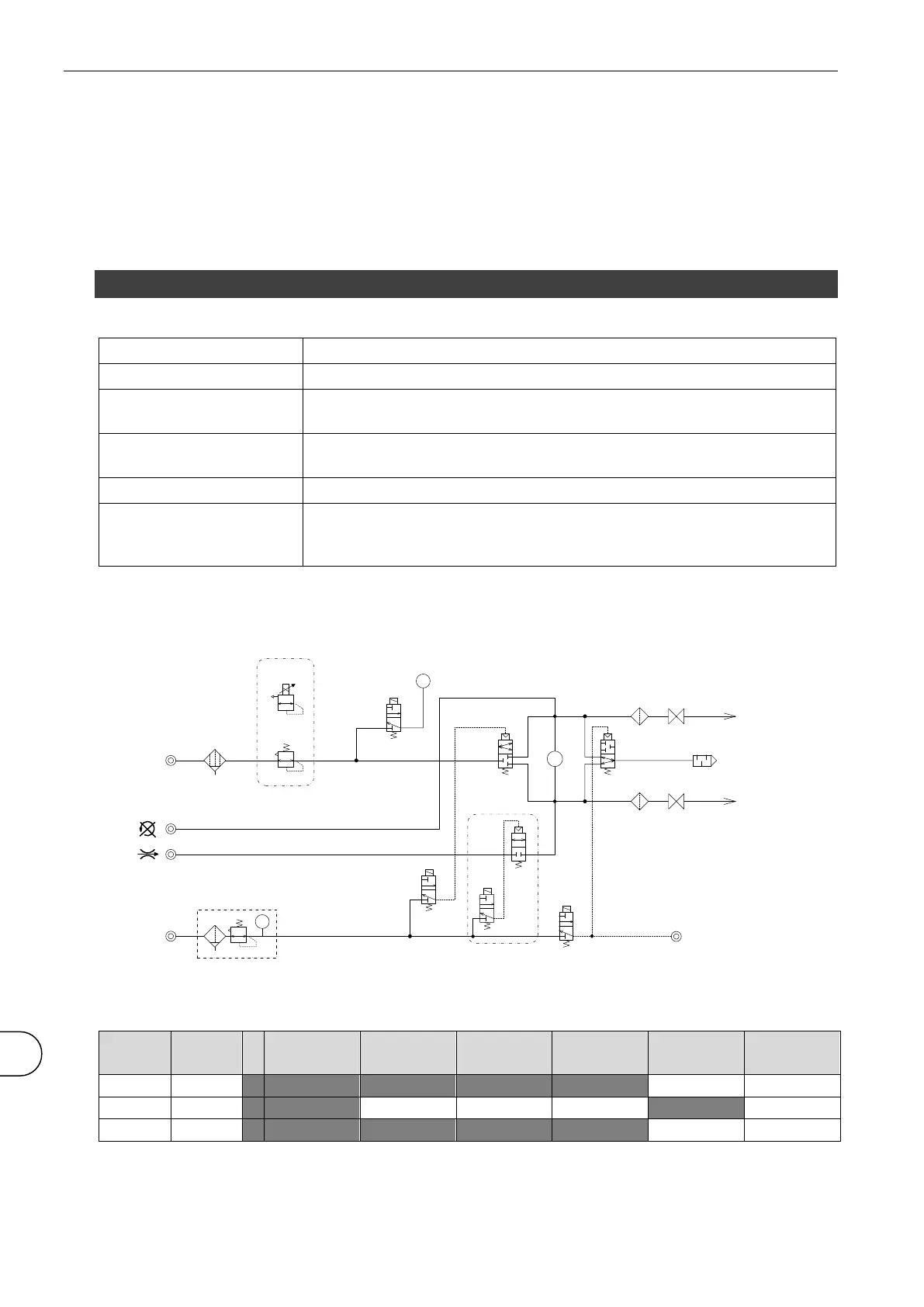

Basic Type Pneumatic Circuit (A1 Medium pressure)

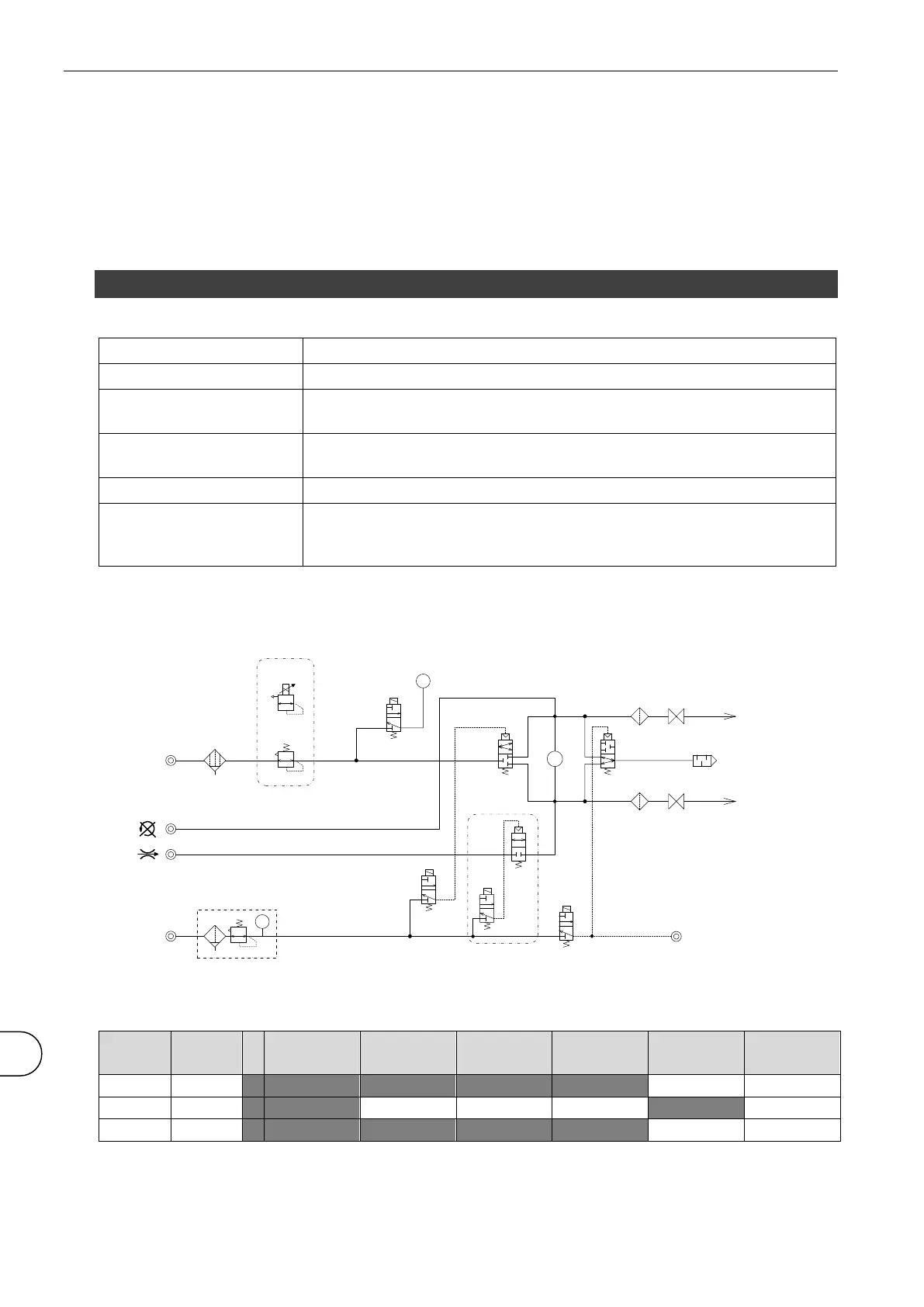

Timing Chart

Solenoid

DL1

CHG DL2 BAL2 DET BLW END

PRESSURE

SOURCE

PILOT

PRESSURE

F1

SV2

AV1

SV4-1

F4

V1

O

O

V1

OPTION R

SV4-2

AV4

O

SV8

OPTION J

400kPa

DPS

P.S

G

V2

MASTER

EXHAUST

WORK

S1

F2

V3F3

AV3

G3 PILOT

PRESSURE PORT

Loading...

Loading...