20 2 Installation

3.4 Tubing for Tested part (Work) and Master

Select tubes considering the follows:

Cosmo recommends rigid nylon tubes that does not expand by air pressure.

• The higher the test pressure is, the thicker the tubes should be, and the larger the part volume is, the

larger the tube diameter should be.

• For small volume parts (approx. 1000mL or less), use compression type fittings but avoid using push-on

type. However, for the tubing whose diameter is 12mm (12 in) or larger, push-on type fittings should be

used because insert type fittings tends to be loosen over time.

• Make the tubes as short as possible. For the parts with small volume, use the tubes with small diameter.

• Tubes for WORK and MASTER sides should be same length and material if the Mastering compensation

is not used.

• Vacuum type models require large diameter tubes. For case of high vacuum, use tubes with smooth

internal surface.

• Mount the tubes so that they don’t move during leak tests.

Recommended Tube (For test pressure of 800kPa or lower)

Manufacturer: Nitta Corporation

Inch size: N2-1 (for test pressure 200 kPa or lower), N2-2

Millimeter size: N2-4

Manufacturer: SMC Corporation

T Series

For the test pressure 800 kPa or higher:

Use steel tubes such as stainless steel.

Select a steel tube based on its intensity.

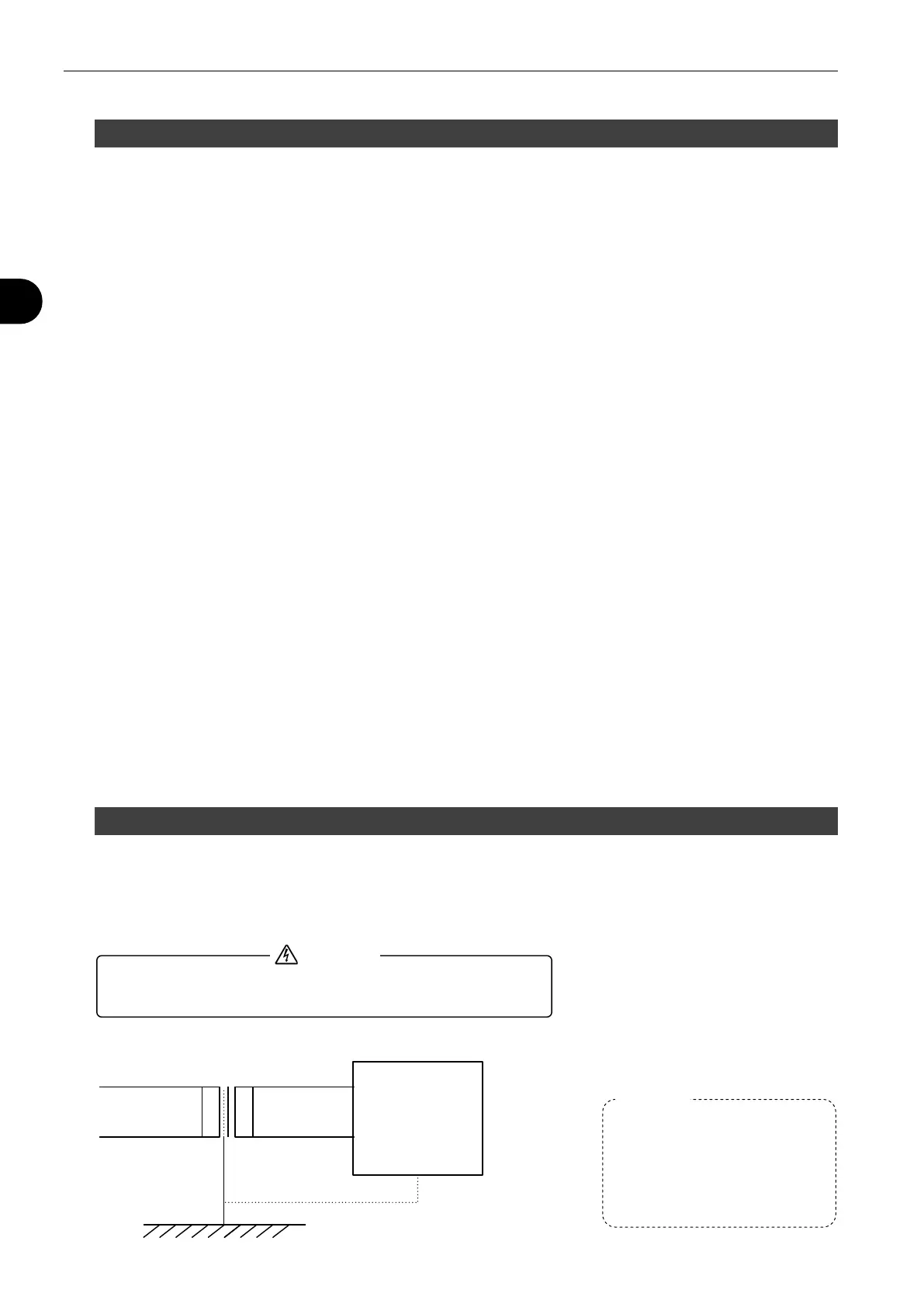

3.5 Power Source

Connect to the power with the enclosed power cord. Required power source is AC 100 - 240 V ±10%.

Make sure ground connection is made.

Use the enclosed power cord for the cases the power source is 125 VAC or lower.

Isolation Transformer

LS-R700

Ground

F.G.

Shield Ground

Please connect a power line that

is free from the sources of noise.

Please use a noise suppressing

isolation transformer if noise

comes from the power line.

Electric Shock

Applying power greater than specified could lead electric shock or fire.

Loading...

Loading...