2 Installation 19

Pressure Connection Precautions

• The source pressure must be clean and dry. When there is water or oil inside of the plant compressor,

an oil mist separator must be used. When there is a lot of water and oil in the compressor, use two or

more separators.

• The lubricated air source should never be connected to the tester.

• Avoid direct wind from cooling vents. It may cause due condensation inside the tubes.

• When using an oil lubricated vacuum pump:

A solenoid valve which opens to atmosphere should be used to prevent oil from entering the LS-R700

when the pump is turned off. The tester should also be installed at a higher level than the vacuum

pump.

• The pressure of the air source must be sufficiently higher than the test pressure and stable

• The air source must have enough flow capacity for the test as well.

• Source pressure should be regulated to at least 100kPa higher than the test pressure with an additional

regulator inline before LS-R700.

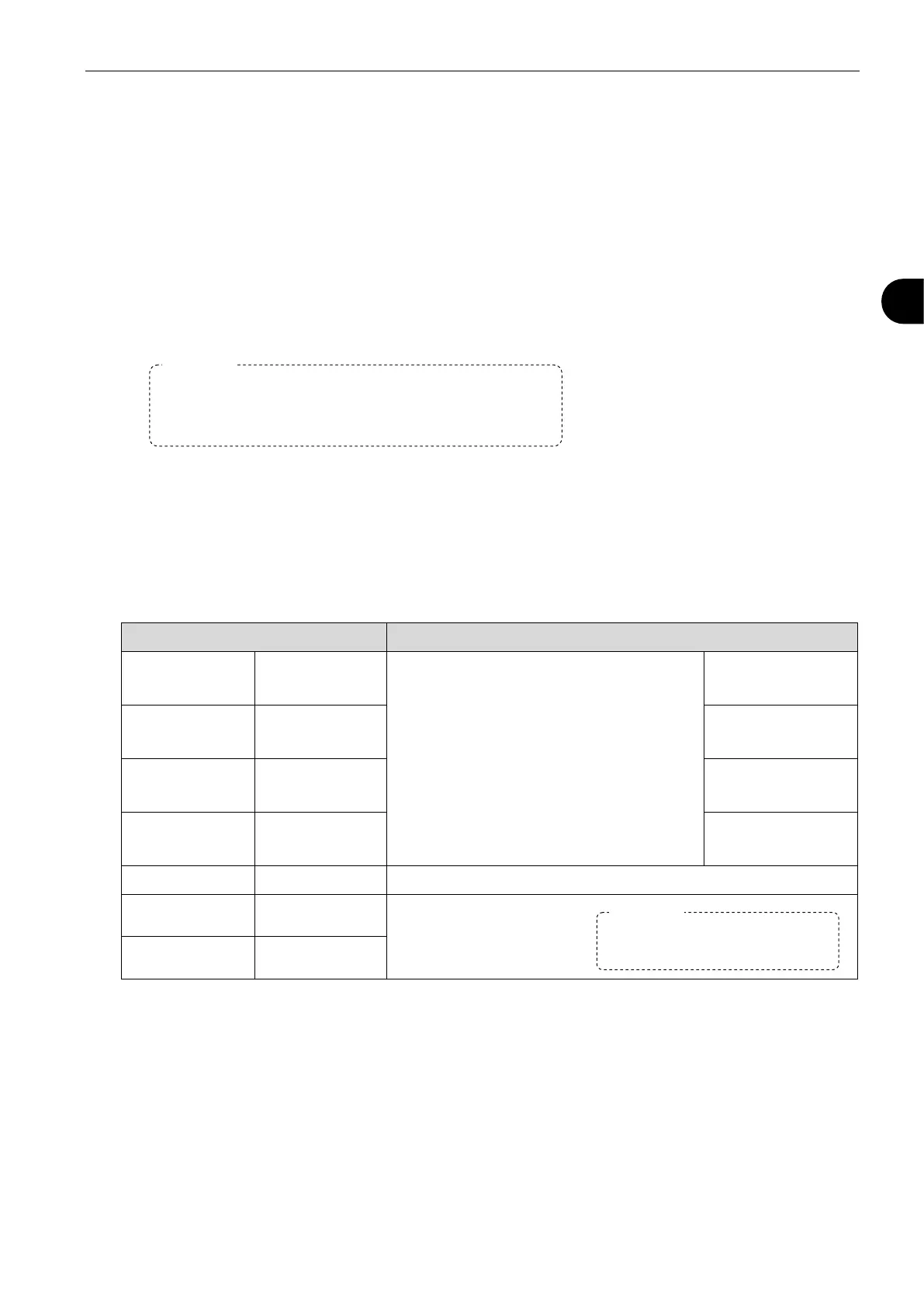

Test Pressure Connection

Port: TEST PRESSURE (“IN” on Oil mist separator) Port Diameter: Rc 1/4

Pressure Range Pressure Source

Micro Low (L02) Up to 20kPa

Connect a pressure source as the follows:

• Sufficiently higher than the test pressure

and stable

• Has enough flow capacity

• Should be regulated to at least 100kPa

higher than the test pressure

L02: Up to 200 kPa

Low (L) Up to 100kPa L: Up to 500 kPa

Low (LR) Up to 95kPa LR: Up to 200 kPa

Medium (M/MR) Up to 800kPa

M: Up to 1 MPa

MR: Up to 1 MPa

High (H20) Up to 2.0MPa Connect a pressure source regulated to the air filter.

Vacuum (V) Down to -100kPa

Connect a vacuum pump

Vacuum (VR) Down to -75kPa

Pilot Pressure Connection

Pilot pressure is to activate air operate valves, which should be regulated between 400 and 700 kPa.

Port: PILOT PRESSURE Port Diameter: 6mm quick disconnect fitting

Once the Differential Pressure Sensor (DPS) is contaminated,

the offset becomes off causing frequent Fails.

Contact Cosmo for repair in those cases.

Be sure that water or oil won’t enter

LS-R700 from vacuum pump.

Loading...

Loading...