Copyright 2008 Baker Hughes Company.

6 | PACE5000/6000 Instruction Manual–English

Chapter 2. Installation

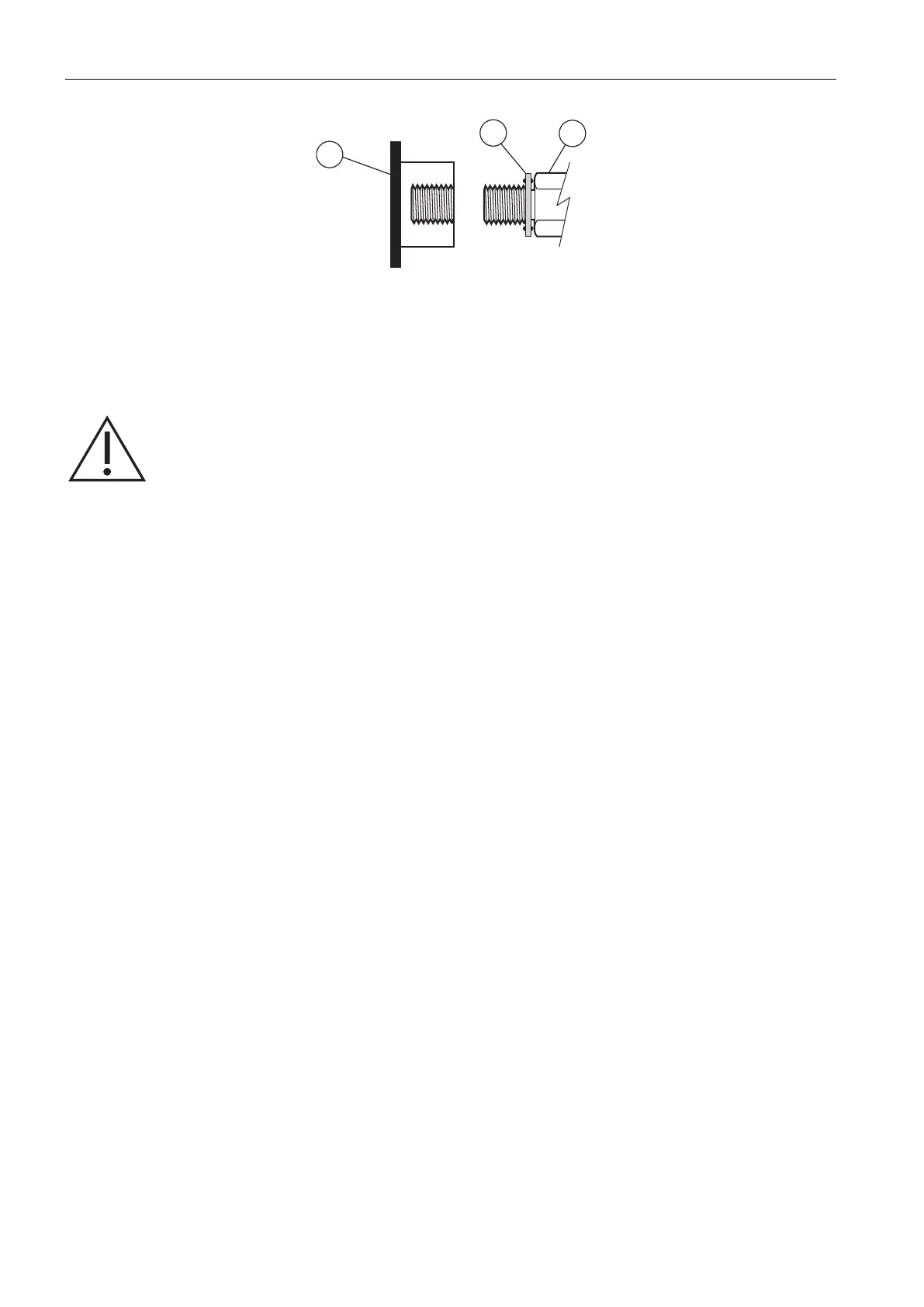

For pressures less than 100 bar (1450 psi), see alternative sealing method in Figure 2-3.

Figure 2-3: Alternative Sealing Method for < 100 bar (1450 psi)

2.5 Connecting to UUT

The pressure should not exceed 1.25 x full-scale or MWP stated on the rear panel of the

instrument.

To protect the instrument from over-pressure, fit a suitable protection device such as a relief valve

or bursting disc.

1. Switch off the power supply before connecting or disconnecting the instrument.

2. Use the appropriate sealing method for all pressure connections. Refer to Section 2.4.2 on

page 5.

3. Isolate the pneumatic pressures and de-pressurize the pipes (tubes) before connecting or

disconnecting the instrument.

4. Make sure the user systems can be isolated and vented.

5. The pneumatic gas must be clean and dry, nitrogen or air. Refer to specification in the Data

Sheet.

6. Connect pressure and vacuum supplies to the SUPPLY + and SUPPLY - connection ports.

7. Connect the Unit Under Test (UUT) to the appropriate connection port.

2.6 System

The safety of any system incorporating the equipment is the responsibility of the assembler of the

system.

The instrument requires a positive pressure supply. Instruments operating in an absolute range

or negative pressure range require a vacuum supply.

A vacuum supply should be used for a fast response for instruments operating near atmospheric

pressure.

1 PACE pressure connector.

2 Bonded seal.

3 ISO228/1 G1/8 pressure connector or adaptor. For

adaptors, see

Section 2.4.1.

CAUTION Do not exceed the maximum pressures stated in the appropriate

component manual for the unit under test.

Reduce pressure at a controlled rate when venting to atmosphere.

Carefully de-pressurize all pipes (tubes) to atmospheric pressure before

disconnecting and connecting to the unit under test.

Loading...

Loading...