Copyright 2008 Baker Hughes Company.

8 | PACE5000/6000 Instruction Manual–English

Chapter 2. Installation

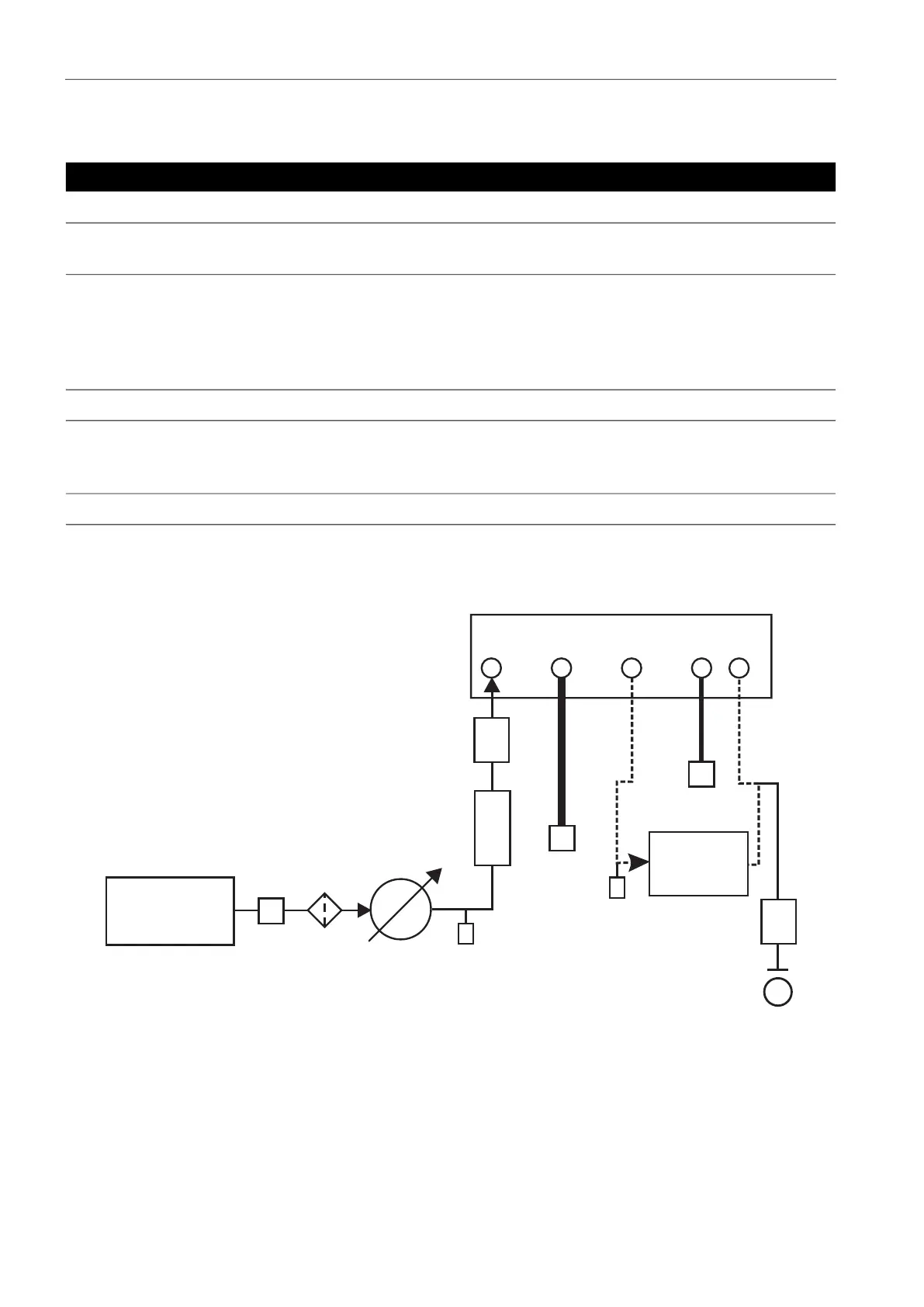

2.7.1 Pneumatic Connection Examples

The following notes apply to the connection examples:

2.7.1.1 Pneumatic Connections without Vacuum Supply

The examples below show a single channel connection detail, using supply equipment described

above.

Figure 2-5: Pneumatic Connections without Vacuum Supply

Note: Refer to Section 6, “Reference,” on page 43 for details of other system components.

Note Description

*

High pressure gas exhaust - depending on pressure range.

**

Optional vacuum system kit, allows the -ve port gas to be directly discharged to

atmosphere, by-passing the vacuum pump.

†

Optimum controller transient response and minimum time to set-point may be

degraded if either the pneumatic supply or vacuum system has restricted flow.

Installing a reservoir volume, which has a larger capacity than the load volume,

located in close proximity to the controller supply ports can improve the controller

response.

‡

Optional negative gauge pressure generator kit.

For ranges of 70 bar (1000 psi) and above, fit a suitable protection device to prevent

overpressure. For example, fit a relief valve or bursting disc. The protection device

must limit the applied pressure to below the MWP.

Optional differential connection kit.

1 Pressure source 2 Conditioner

3 Filter 4 Regulate to between 110% full-scale and

MWP

5 Diffuser * 6 Unit under test

7 Optional reservoir † 8 Protection device

9 Optional differential connection 14 Manual external vent valves

a Atmosphere

Loading...

Loading...