Position of the hook and needle

46 Service Instructions 827/827-M - 01.0 - 05/2019

10.2 Adjusting the hook side clearance

Order

First, check the following adjustments:

• A straight and undamaged needle has to be inserted ( Operating

Instructions)

• Needle bar linkage( p. 35)

• Looping stroke position ( p. 44)

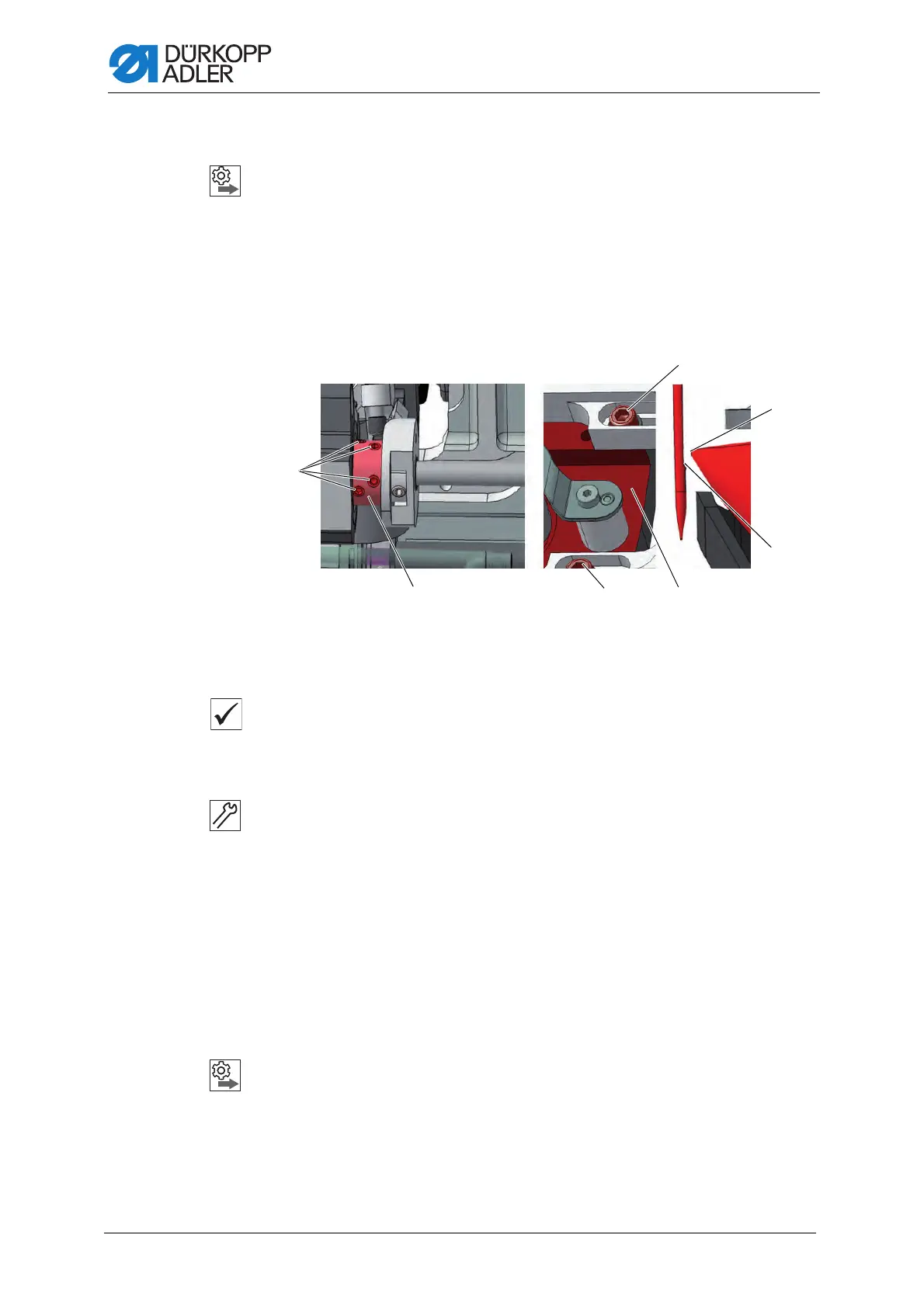

Fig. 30: Adjusting the hook side clearance

Proper setting

1. Lock the machine in place at position 1 ( p. 22).

The distance between the hook tip and the groove of the needle is

no greater than 0.1 mm.

To adjust the hook side clearance:

1. Tilt the machine head ( p. 14).

2. Open the throat plate slide ( p. 18).

3. Lock the machine in place at position 1 ( p. 22).

4. Loosen the screws (3).

5. Loosen the threaded pins (1) for the set collar (2).

6. Move the hook support (3) sideways such that the distance between

the hook tip (6) and the groove for the needle (5) is 0.1 mm at most,

without the hook tip (6) touching the needle.

7. Tighten the screws (3).

Order

Then check the following adjustment:

• Needle guard ( p. 48)

(1) - Threaded pins

(2) - Set collar

(3) - Screws

(4) - Hook support

(5) - Groove

(6) - Hook tip

Loading...

Loading...