Resistance welder MULTISPOT MI-100control

Operation

56

Adjusting the contact force

NOTE!

Be sure to set the correct contact force with respect to the current welding / OEM

program selected – because:

If the contact force of the electrodes is too high, the electrical resistance will be too

weak which, in turn, will affect the welding job.

If the contact force is too weak, the welding spots may erode and leave holes in the

sheets.

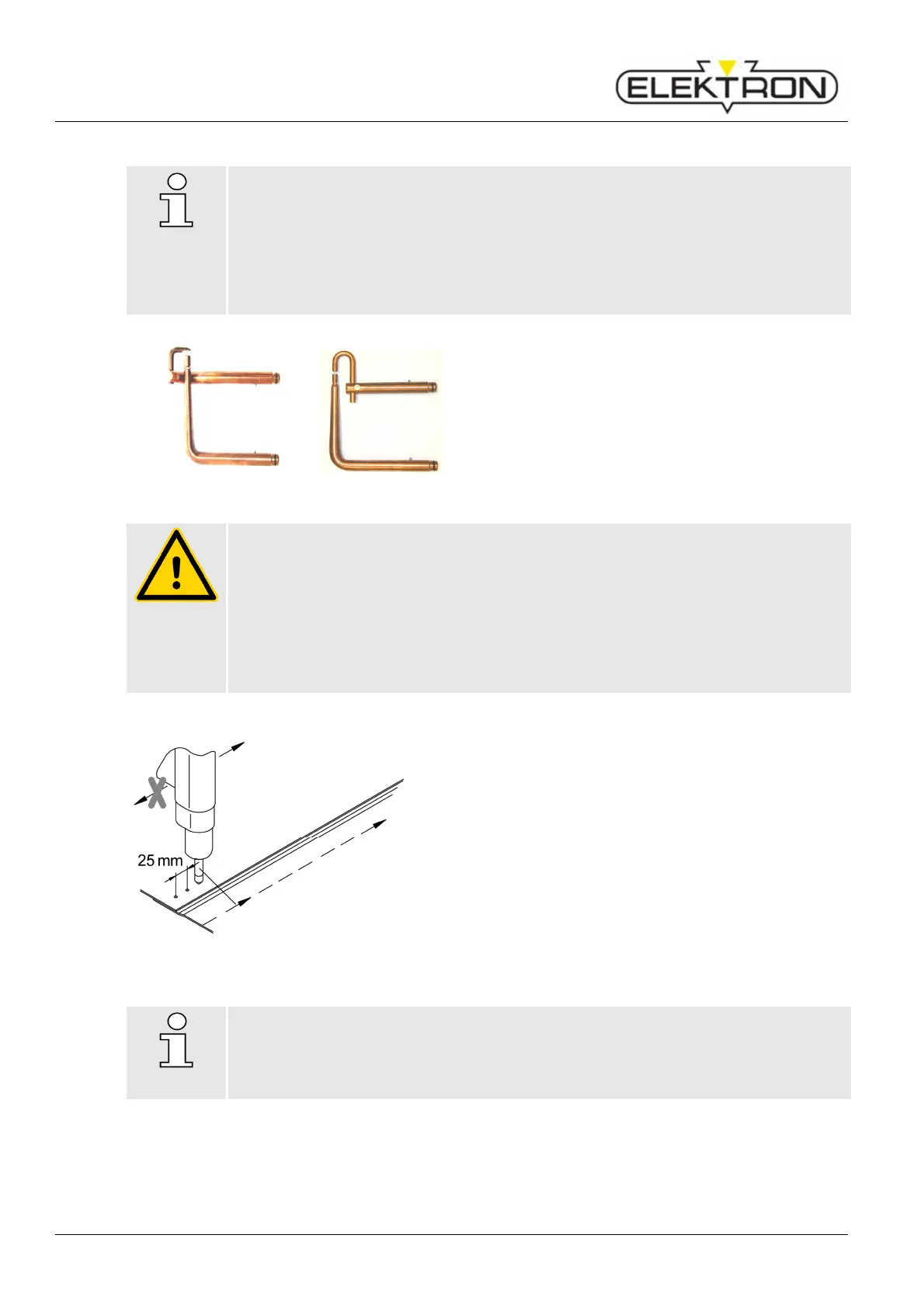

Fig. 72: Contact force ≤ 240 daN

When using the electrode arm configuration shown to the left, 12-mm electrodes will

slightly bend if the contact force is set higher than 240 daN (540 lb f).

Therefore:

Ask yourself, whether the job at hand could be handled just as well with a different

configuration.

When you have to use the configuration as shown here, make sure the contact

force does not exceed 240 daN (540 lb f) / 4.6 bar (67 Psi).

Distances between welding spots

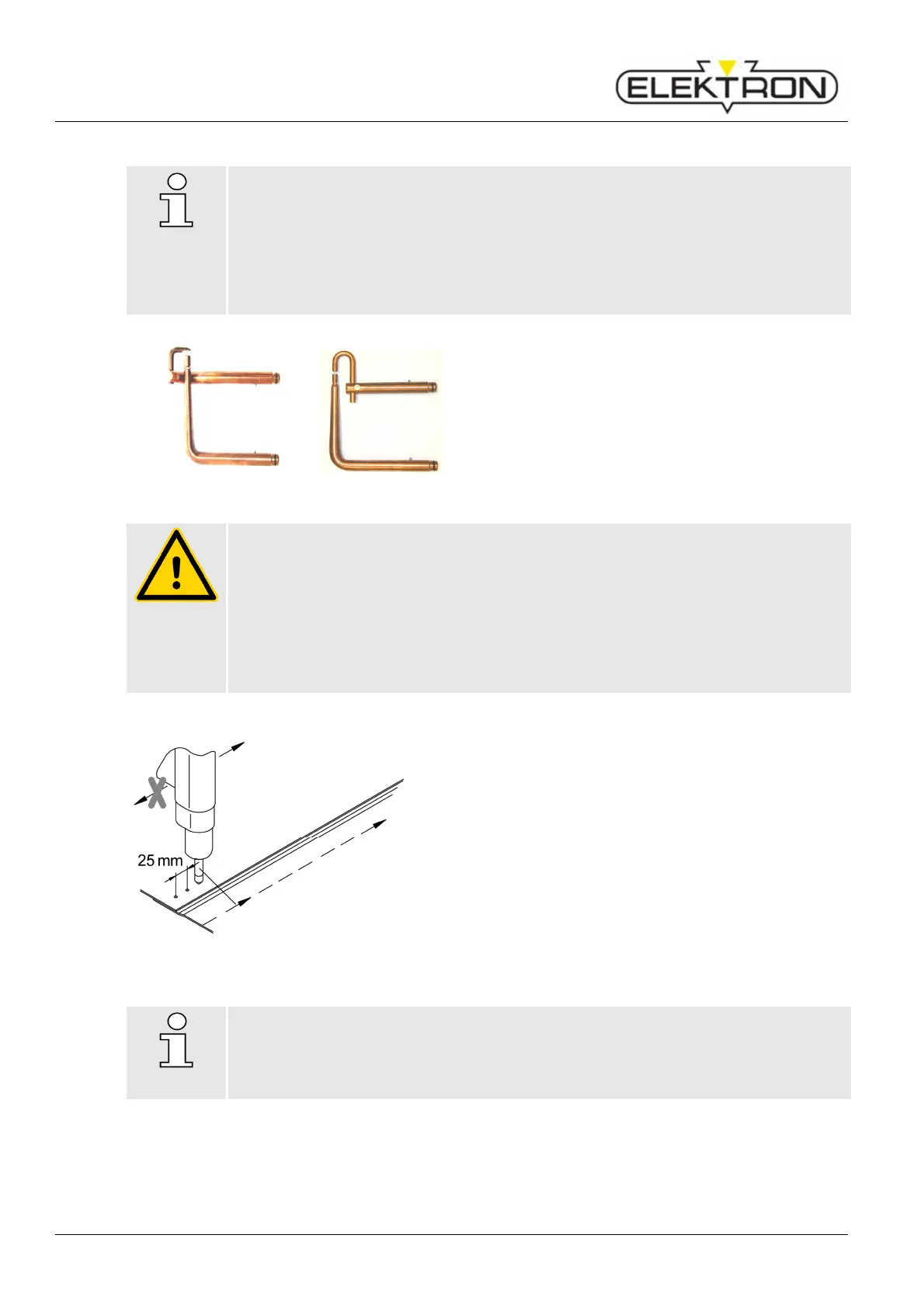

Fig. 73: „Distances should not be too short.”

Don’t keep the distances between welding spots too

short (25 mm approx.). Otherwise, the weld current

might affect the spots (that have already been applied)

a second time.

Lifetimes of electrode caps

NOTE!

The perfectly sound condition of the caps is essential for good welding results.

Electrode caps must be milled (or replaced) after 50 welding jobs, especially when

working with high strength and / or galvanised steel (

see “6.1.2”).

Loading...

Loading...