Resistance welder MULTISPOT MI-100control

Operation

69

6.9.3 High-speed planishing hammer “SAH” (special accessory)

Small dents, scratches or hail pitting can easily be removed with the high-speed planishing

hammer.

1. Grind damaged area to a bright metal finish.

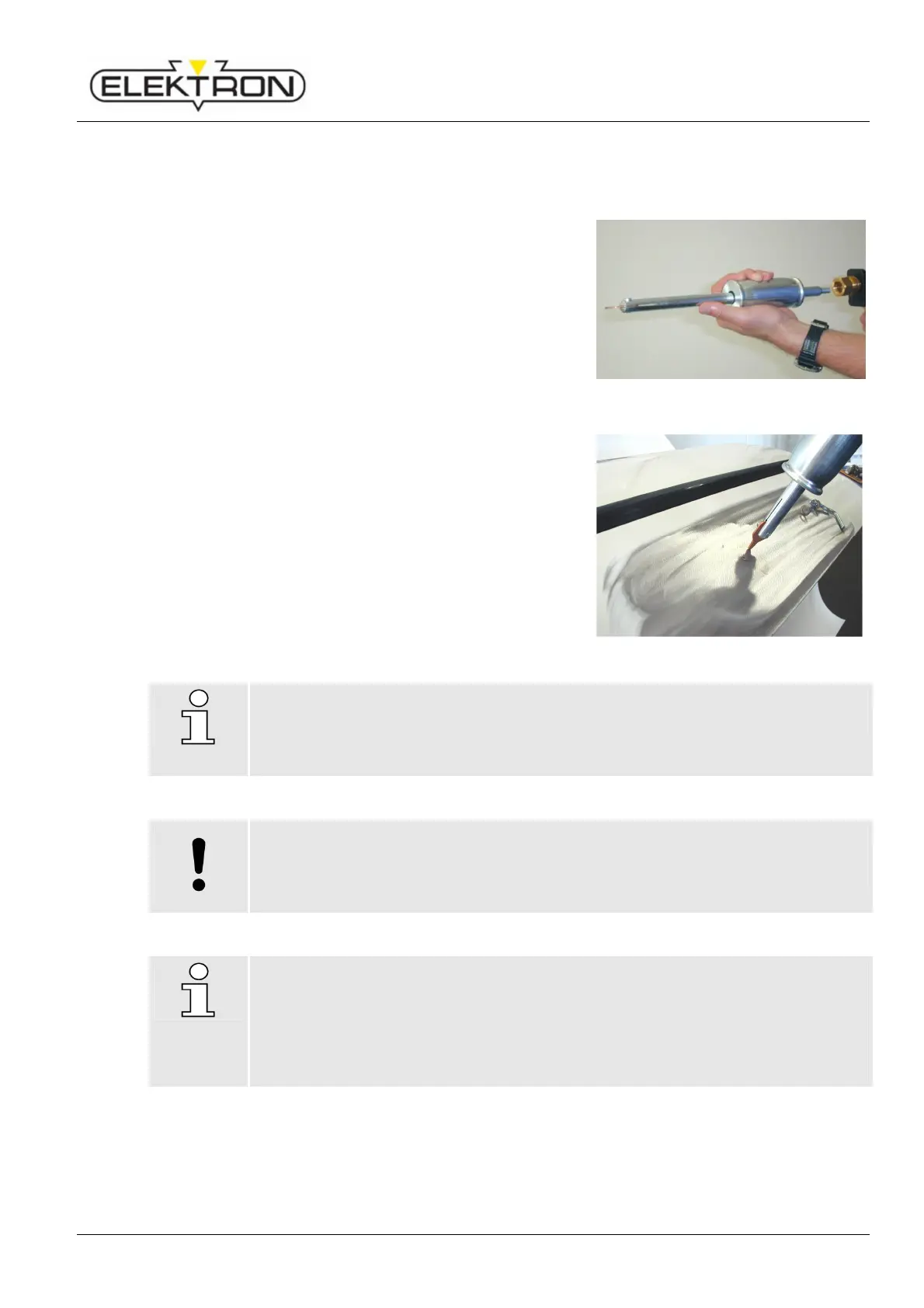

2. Insert high-speed planishing hammer (with weld on tip)

into the gun (Fig. 96).

3. Select “SAH” mode and sheet thickness on display (Sheet

steel thickness above 0.8 mm cannot be selected).

4. Fine-adjust +/–, if necessary.

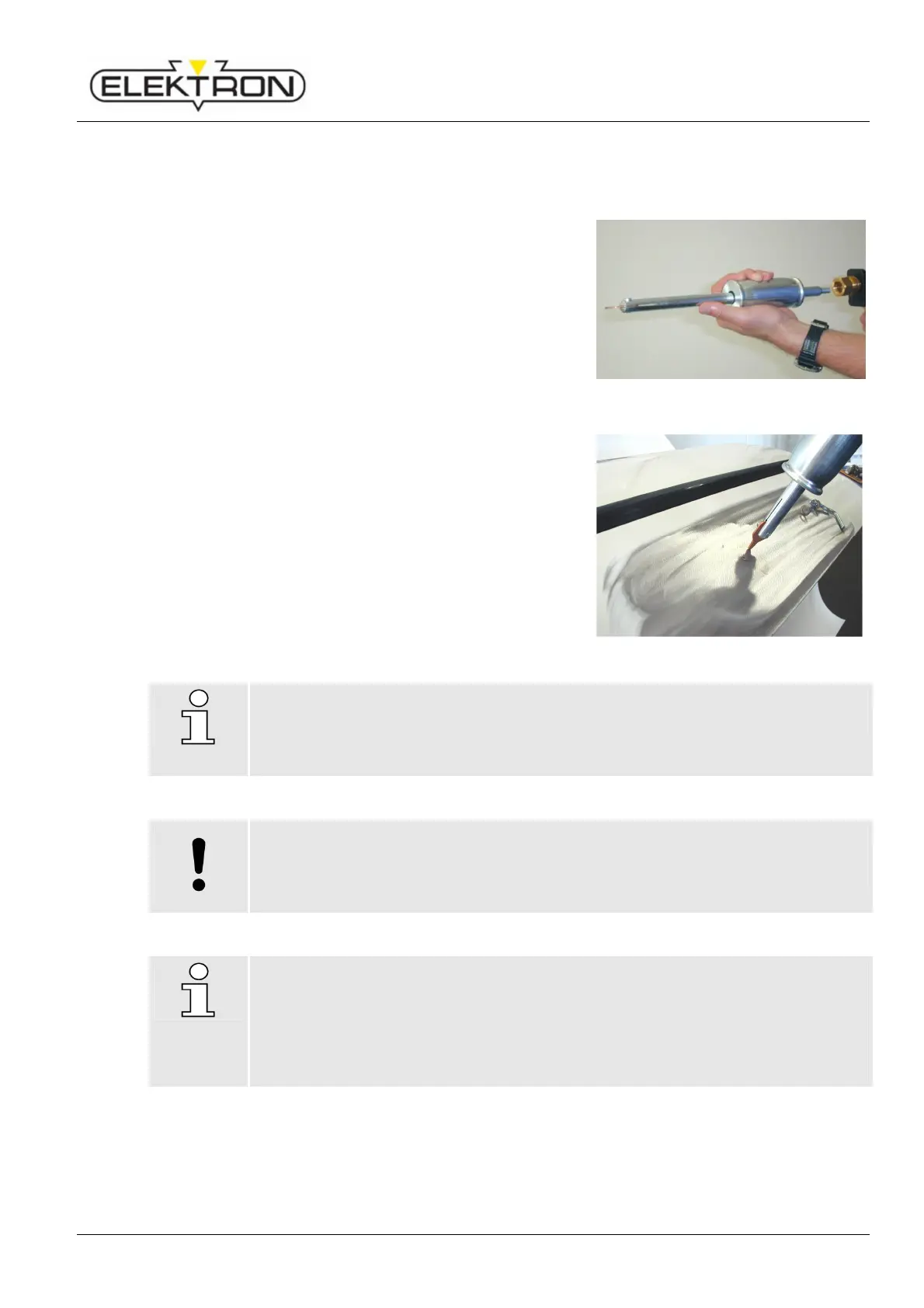

5. Position weld-on tip of the hammer in the damaged area.

6. Press release button of the gun and weld-on welding tip.

7. Beat out the dent.

8. Twist the high-speed planishing hammer (SAH) off the

sheet steel. Select the weld time as short as possible.

9. From time to time, dress the weld-on tip with a file.

Fig. 96: High-speed planishing hammer ‚SAH’

(special accessory)

NOTE!

Repeat the procedure until the damaged area is entirely repaired.

Heavy dents only remove with extractor tool and 8mm washer, as otherwise the

welding gun might be damaged!

NOTE!

If the weld-on tip is worn out, it should be replaced.

For replacement unscrew the socket-head cap screw at the top of the hammer (SAH)

and remove the worn out weld-on tip. Position new weld-on tip and properly tighten

socket-head cap screw!

For item number please see spare parts list.

Loading...

Loading...