Resistance welder MULTISPOT MI-100control

Operation

70

6.9.4 Pushing-in dents

Small high spots dents caused by overlapping load in the boot or by beating out with pulling tool can

easily be flattened with contact piece (only for sheets up to 1 mm thickness).

Insert contact piece U-B (Fig. 97) into the gun.

2. Select “pushing in dent” and sheet thickness

(≈ projection) on display.

3. Fine-adjust, if necessary.

4. Position welding gun with contact piece U-B on the dent

and press firmly.

5. Press release button of the gun.

6. The welding program performs automatically.

Fig. 97: Contact piece U-B

NOTE!

Do not lift off welding gun until the welding time has expired

6.9.5 Shrinking sheet

1. Grind damaged area to a bright metal finish.

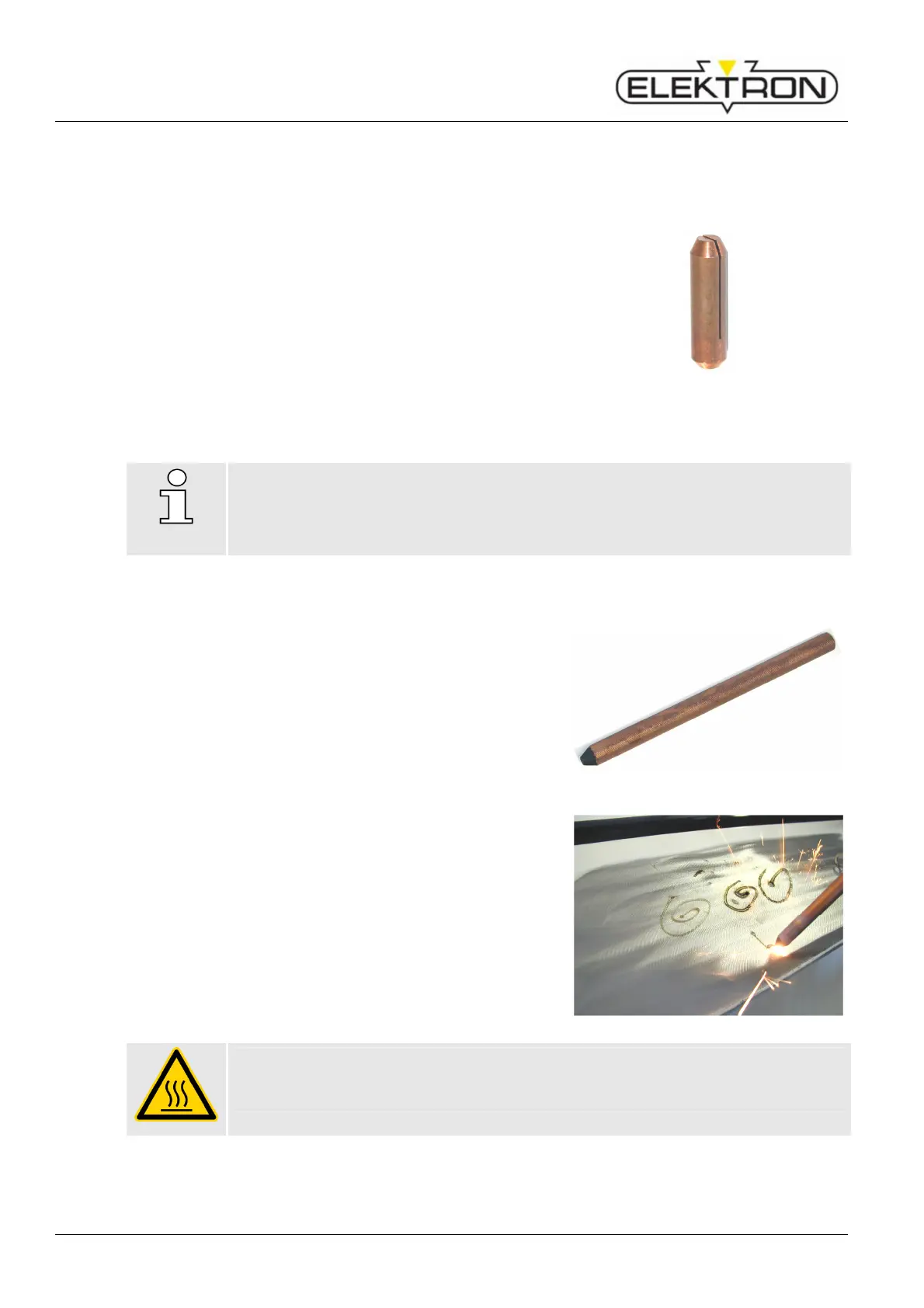

2. Insert carbon electrode (Fig. 98) into contact piece of the

welding gun.

3. Select “anneal/shrink” on display (time controller is now

inoperative).

4. Locate the damaged area by finger pressure.

5. Position carbon electrode in the centre of the damaged

area.

6. Press and keep hold of release button of the gun and

heat the metal sheet with spiral motions from the centre

outwards.

7. Immediately quench the sheet with a wet cloth or

compressed air.

Repeat if necessary.

If necessary, the degree of annealing can be increased or

decreased on the display (sheet gauge) by one level up

or down.

Fig. 98: Carbon electrode

Danger of injury and fire!

The carbon electrode becomes red-hot!

Wear protective gloves!

Loading...

Loading...