Resistance welder MULTISPOT MI-100control

Maintenance

81

8.2.1 Cleaning

negligent or improper cleaning jobs

may entail damage to property!

If you do not clean the welder at all or use aggressive cleaning agents or –methods,

there is a danger of damage to property.

Therefore:

Do not use aggressive cleaning agents and / or –methods.

Do not use steam cleaners and / or pressure washers.

Be particularly careful with the display.

Be sure to clean the welder on a regular schedule, especially around air vents.

Adequate dissipation of heat must be ensured.

wear parts constitute a hazard!

Wrong and / or defective spare and wear parts may constitute a safety hazard and may

entail errors, damage and even total destruction.

Therefore:

Always use genuine spare and wear parts made by the manufacturer.

Clean the welder with a dry, lint-free cloth. For persistent dirt, use a textile cloth that has

been slightly damped with a mild detergent.

As for the display: just dust. Be careful not to scratch the display.

8.2.2 Maintaining the pneumatic unit

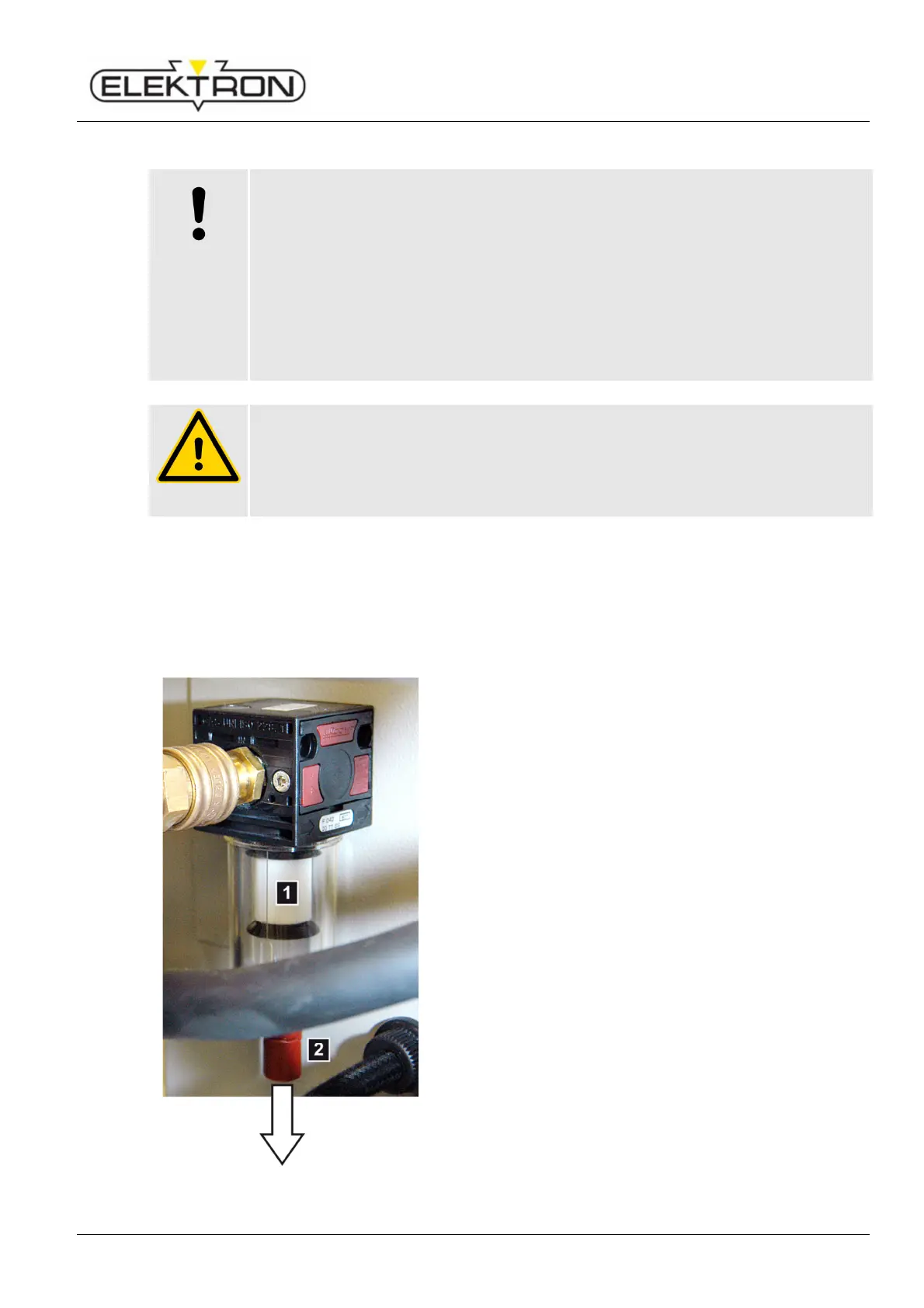

Fig. 103: Pneumatic unit

1. Visually check the compressed-air filter (Fig. 103/1).

Replace, when you see any accumulation of dirt.

2. Visually check the water separator (Fig. 103/2)

under the compressed-air filter for residues of water.

If you find any accumulations of water, pull of the cap in

the direction indicated by the arrow and empty water from

the separator.

Loading...

Loading...