Resistance welder MULTISPOT MI-100control

Troubleshooting

75

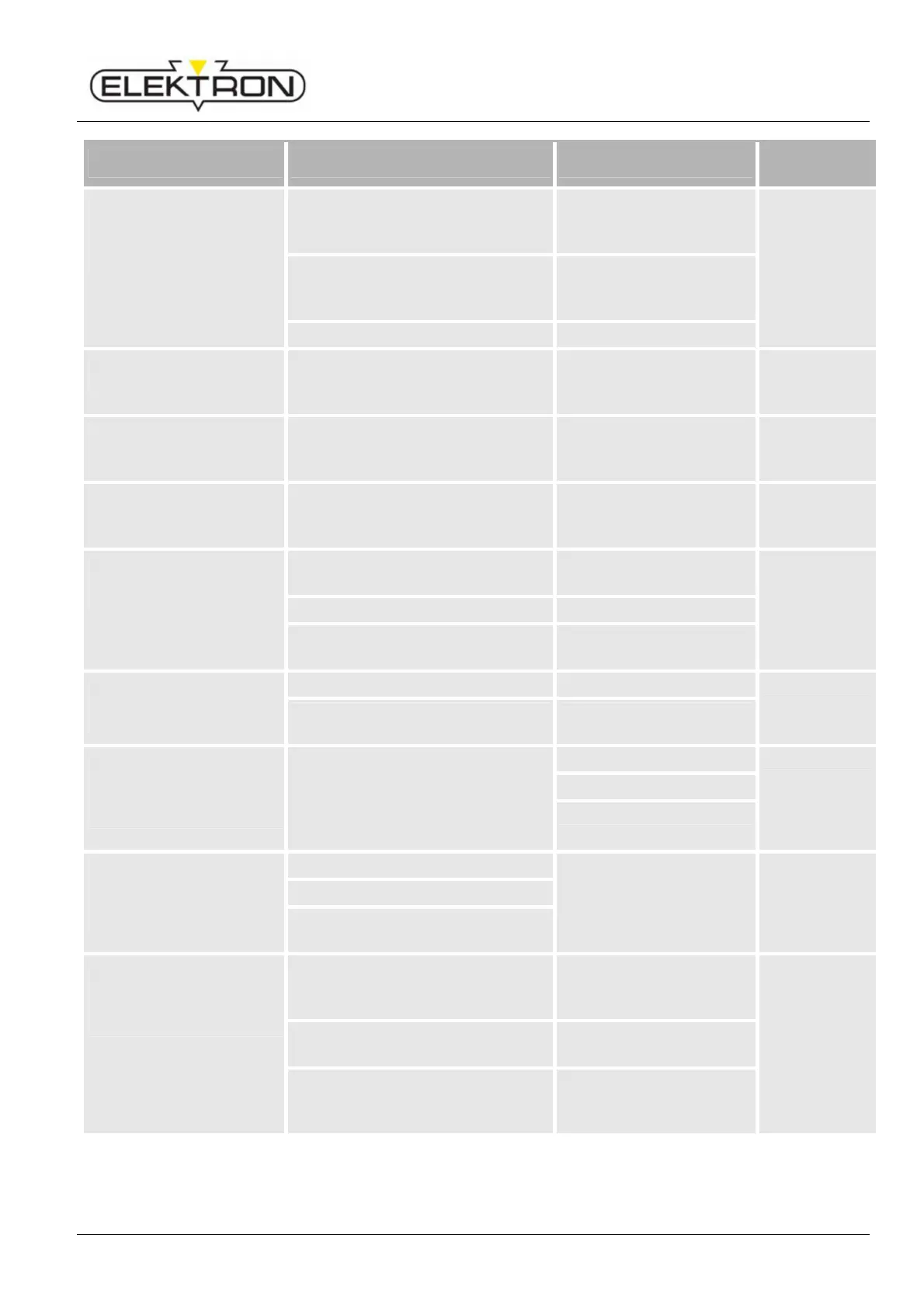

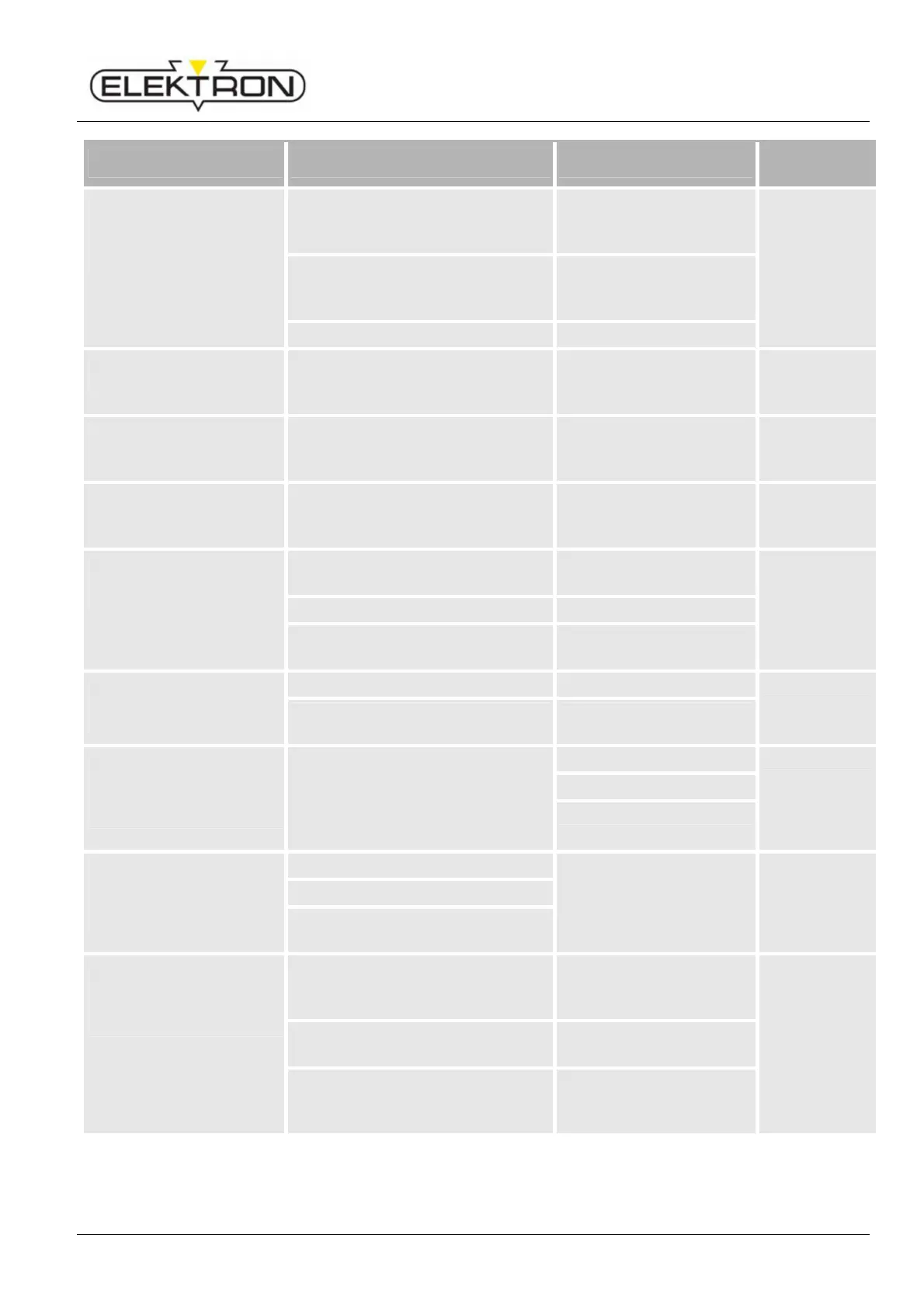

Message What’s the problem What should be done?

Who should

do it?

Pliers control not

connected. Please connect

plug.

The plug for measuring the

impedance at the front sheet has not

been connected.

Replace plug. Operator

The impedance measuring cable is

defective.

Check the cable.

If the cable must be

replaced, call service.

The IO board is defective. Call service.

Work pressure too low.

Compressed air has not been

connected. Pressure too low.

Check compressed-air

connection and –pressure

“5.6”.

Operator

Timeout occurred on CAN

bus

The CAN bus between the control

unit and IO board detected too many

errors.

Check the cables installed. Service

Please check cap and

change cap, if necessary.

Message appears at start-up and

after 50 welding spots.

Check the caps. Mill them /

replace them, if necessary.

“6.1.2”.

Operator

Central connection

overheated.

The central connection is overheated.

Interrupt current welding

job. Let the pump run.

Operator

Central connection is not tight. Re-tighten.

The plug of the temperature sensor

has gone loose.

Re-tighten.

No tool recognised. Please

insert a tool.

A tool has not been connected. Connect a tool. Operator

Otherwise, the tool must be

defective.

Replace the tool.

Wrong tool for selected

program – Please connect

tool as per indication.

The tool connected is not right for the

welding program that has been

selected.

(Message can occur only with OEM

and own programs.)

Check selected program. Operator

Connect the required tool.

Check the programming.

No electrode identification

available. – Select type of

electrode.

You’re using uncoded electrodes. Set the type of electrode

manually

“6.4.3”.

Operator

Electrode ID of the tool is defective.

The impedance measuring cable is

defective.

Tool is overheated. –

Welder remains locked until

cooled off.

The tool is overheated. Have the throughput of the

cooling water pump

checked.

Service

Temperature sensor of the tool is

defective.

Have the temperature

sensor of the tool checked.

The throughput of water inside the

tool is too low.

Have the throughput of the

cooling water pump

checked.

Loading...

Loading...