Installing the K Chassis

Enterasys K-Series K6 Chassis Hardware Installation Guide 3-11

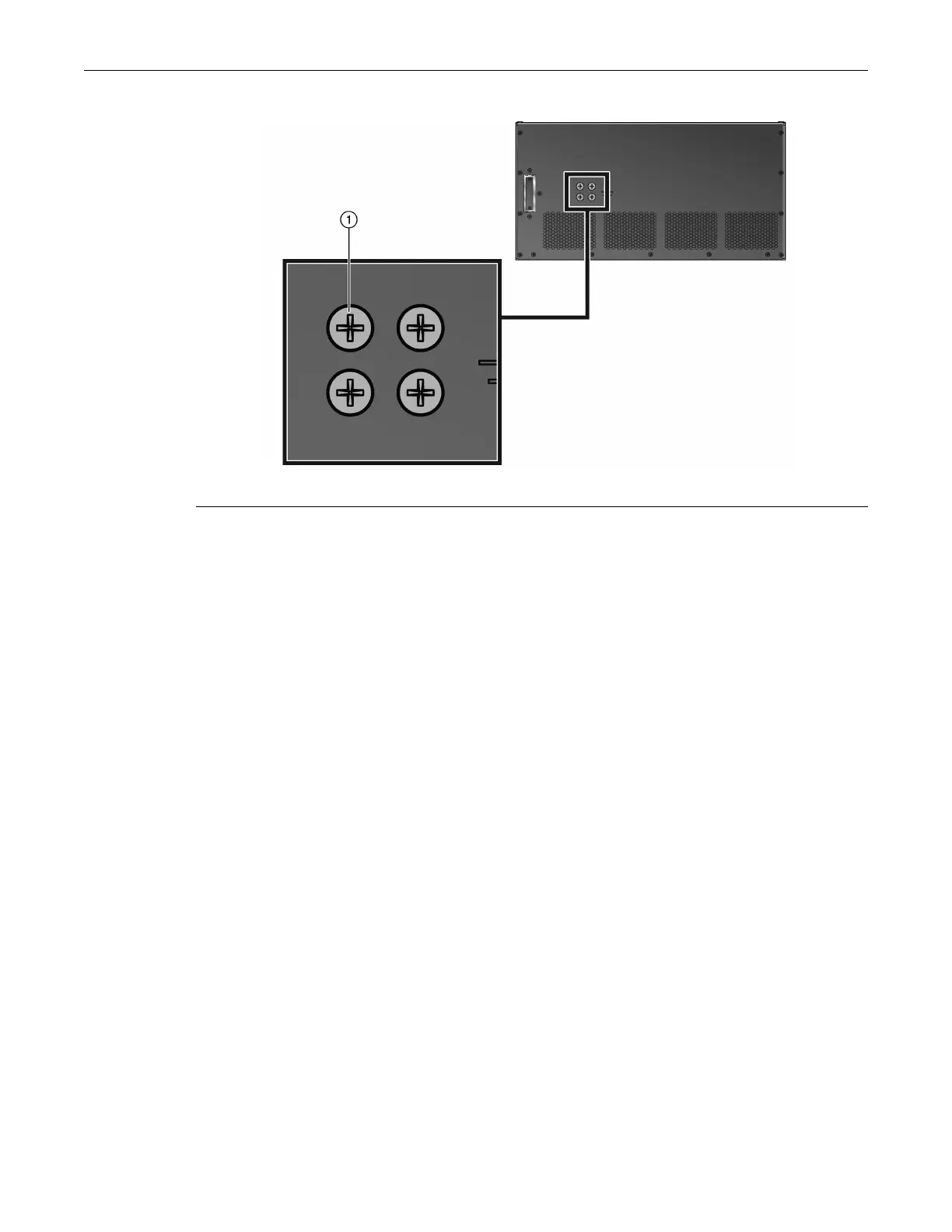

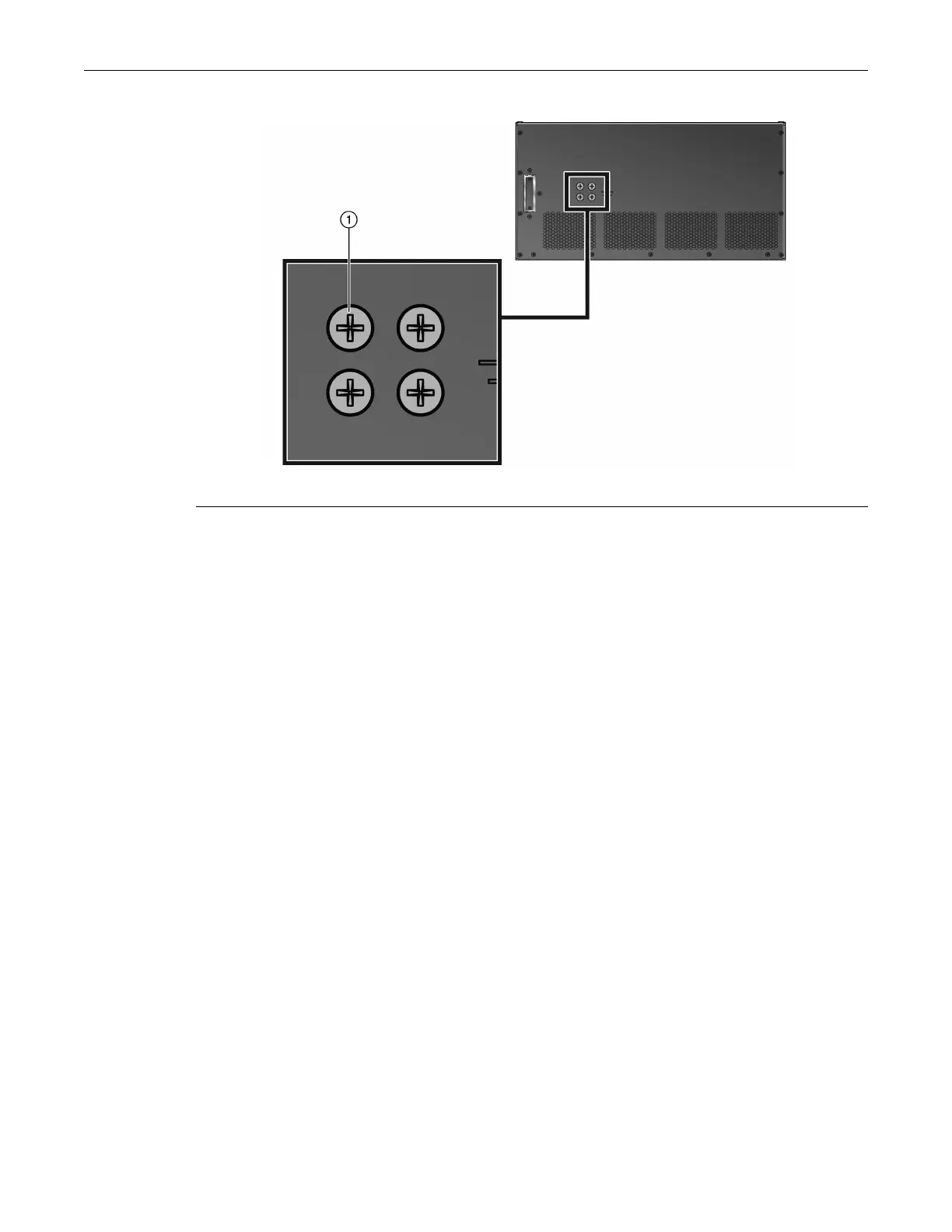

Figure 3-10 Telcordia GR-1089 Grounding Hole Pattern

Alternategroundingrequirementswhenaconnectionisneededbetweenthechassisandthe

enclosuremetalwork,anearbypointontheCentralOffice(CO)Groundsystem,orearthground.

Theconnectionismadeusingoneormoregroundingwires(asneeded)fabricatedfroman8AWG

(6

2

mm)strandedcopperwire.Tofabricateandinstallagroundingwire,proceedasfollows:

1. Cutan8AWG(6

2

mm)stranded‐copperwiretolength,longenoughtoreachfromthe

groundinglocationofthechassistotheselectedgroundinglocationontheCO Ground,earth

ground,orenclosuremetalwork.

2. Installalistedtwo‐holecompression‐typeconnectoronbothendsofthegroundingwire.

3. Applyasuitableantioxidanttothe

chassisgroundinglocationandunpainted su rface

groundinglocationontheCOGroundorenclosuremetalwork.

4. Connectonegroundcabletwo‐holeconnectortothechassisusingtwoofthe1/4‐20screws

shippedwiththechassis.Connectthetwo‐holeconnectorattheotherendofthecabletothe

CO

Groundorenclosuremetalworkusinguser‐suppliedscrews.

5. Torquescrewsto67inchpounds(±5%).

NationalDeviations:

•InNorway,Sweden,andFinland,thesameprocedurecanbeusedforapermanentprotective

earthgroundconnectionasrequiredbytheirnationaldeviationtoIEC60950,Section5.1.7.

•InDenmark,thechassismust

beinstalledutilizingaTypeBgroundedplug.

1 Ground screws

Loading...

Loading...