Stylus Photo R1900/R2880/R2000/R2000s/SC-P400 Series Revision I

SC-P400 Series Adjustment 219

Note "*": Mac OS is not supported.

Calibration principle

Measuring a color chart print result (ink discharge amount) in a calibrator.

Created Color ID information based on the obtained color difference values

(L*, a*, b*) is stored on the printer. When printing, the printer driver takes the

Color ID to correct the number of ink droplets (dot generation rate) for each of

different sized droplets of each colors.

Correlation with Head ID adjustment

Head ID: In the printhead manufacturing process, ink discharge amount of each

head is actually measured to get individual characteristic information. The

information is the Head ID that was set to revise a characteristic difference

between the heads. The Head ID is shown with a label on the each printhead,

therefore you must input the Head ID to the printer after printhead exchange.

Flow of the Colorimetric Calibration

The following steps show the Colorimetric Calibration:

1. Print a nozzle check pattern. If there is nozzle missing, run a head cleaning.

2. Print a color chart with the printer which you want to calibrate via

ColorBase2.

3. Scan the printed color chart with a calibrator.

4. ColorBase2 calculates a Color ID from the scanning result and calculation

parameter of the colorimetric calibration.

5. Write the Color ID to the printer. When printing, printer driver refers to the

data of the User Color ID area.

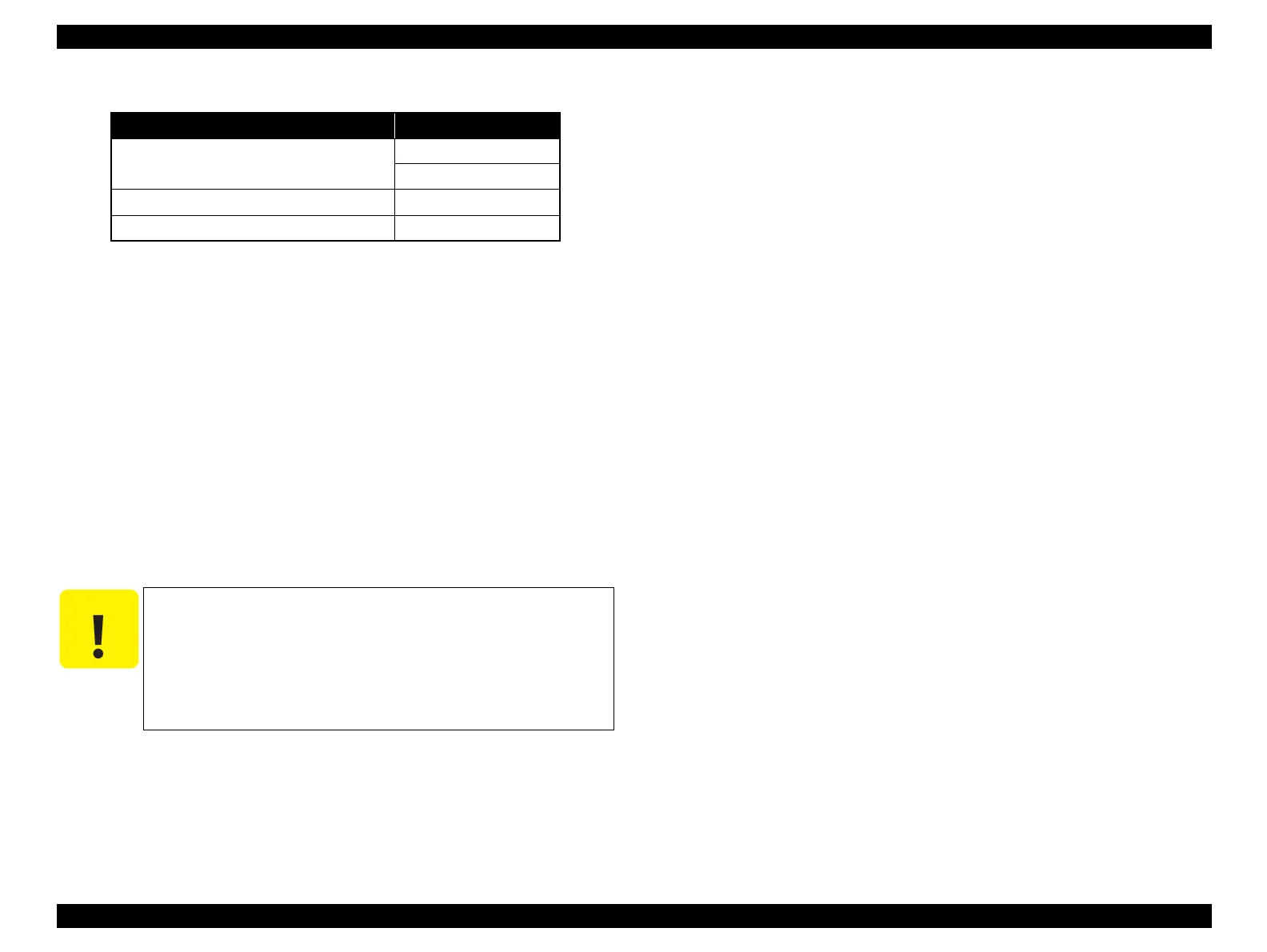

Table 9-10. Support OS of EPSON ColorBase2

OS* bit

Windows XP SP3

32

64

Windows 7 SP1 or later 32/64

Windows 8 / 8.1 32/64

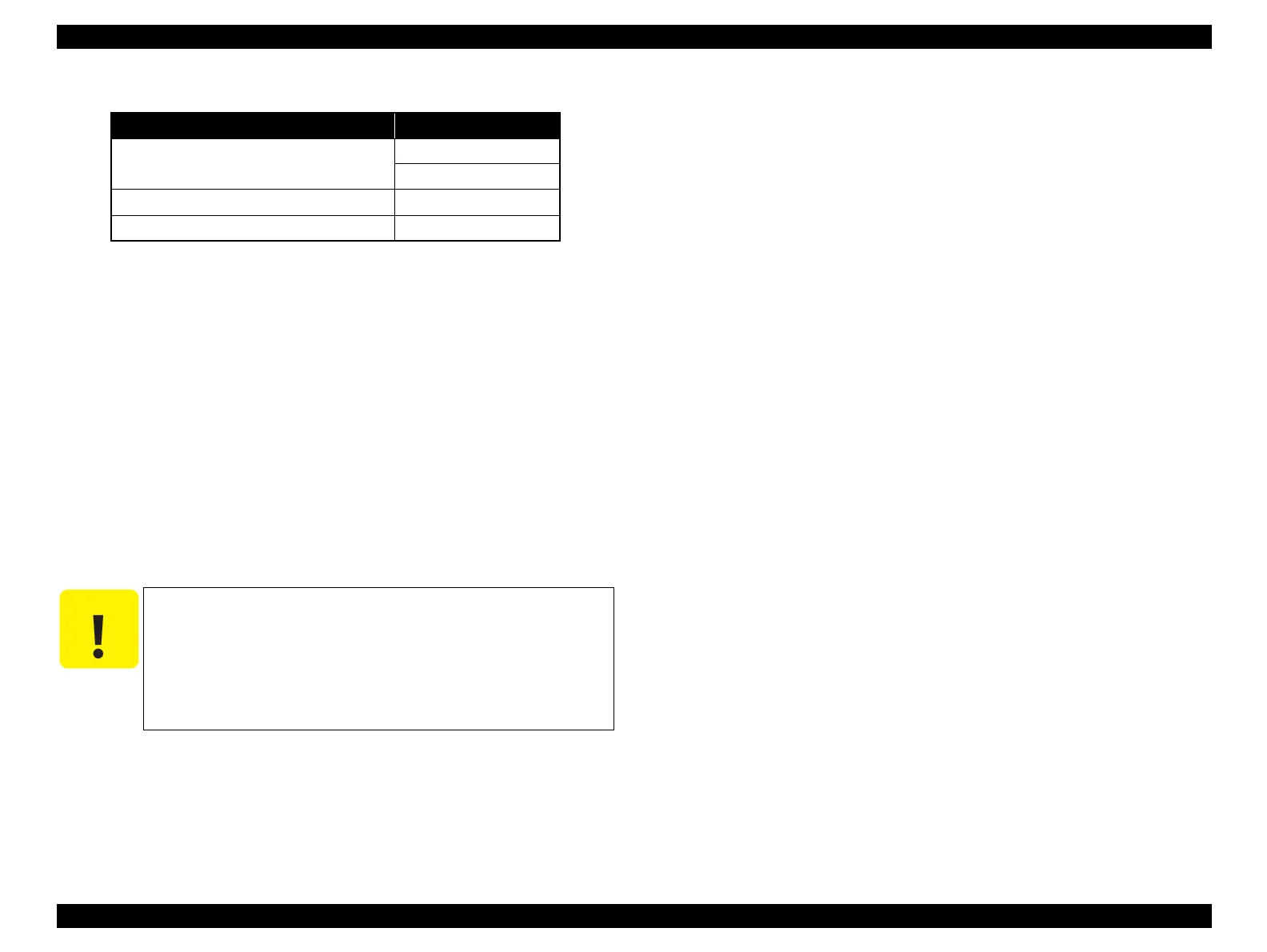

Before performing Colorimetric Calibration, the

conventional Head ID must be pre-registered.

If you do not perform Colorimetric Calibration after

performing Head ID adjustment, the printer will be

controlled only by the Head ID. In that case, the color

precision is not guaranteed.

Loading...

Loading...