EPSON WF-C5790/WF-C5790a/WF-C5710/ET-8700/WF-C5210/WF-C5290/WF-C5290a Revision A

Troubleshooting Troubleshooting procedure 158

Confidential

Troubleshooting

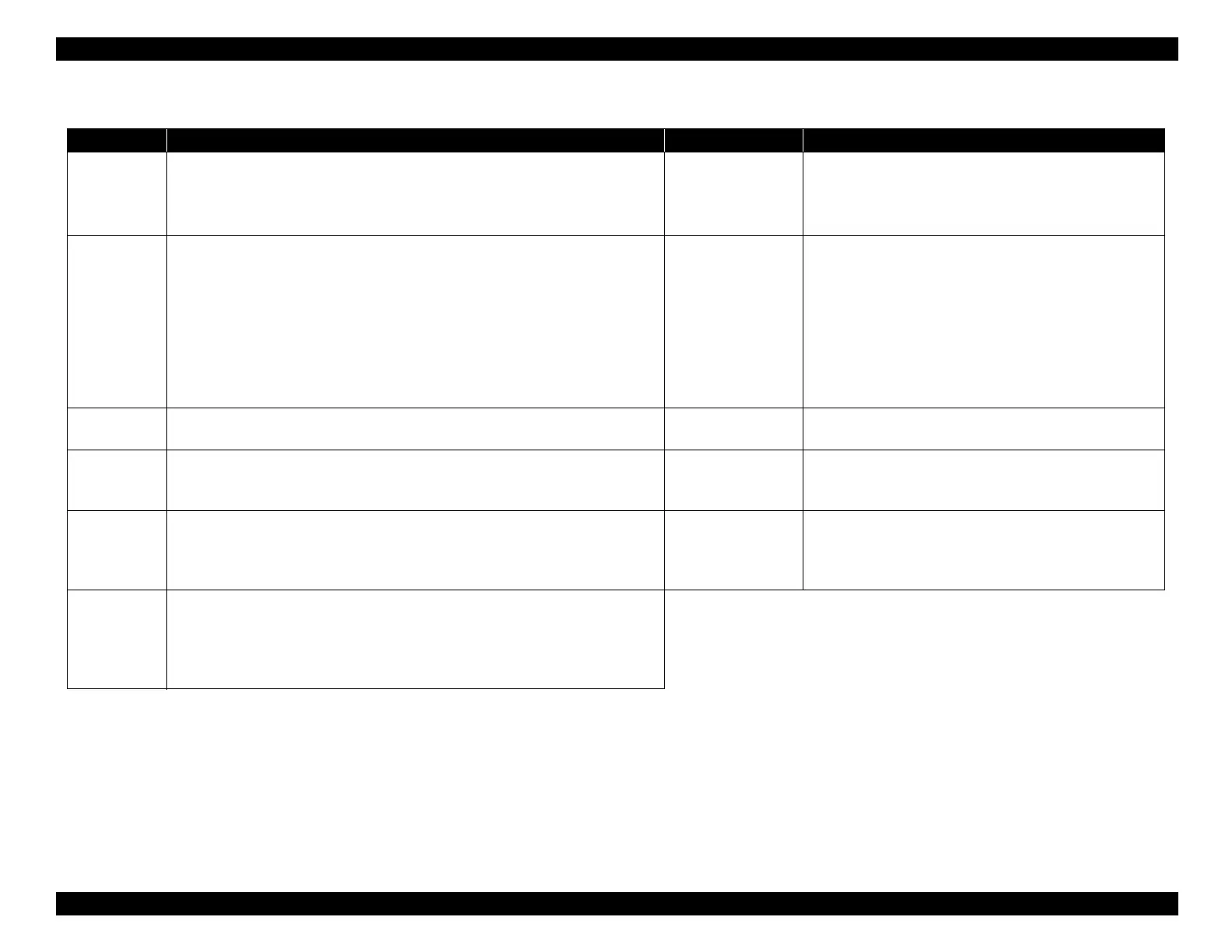

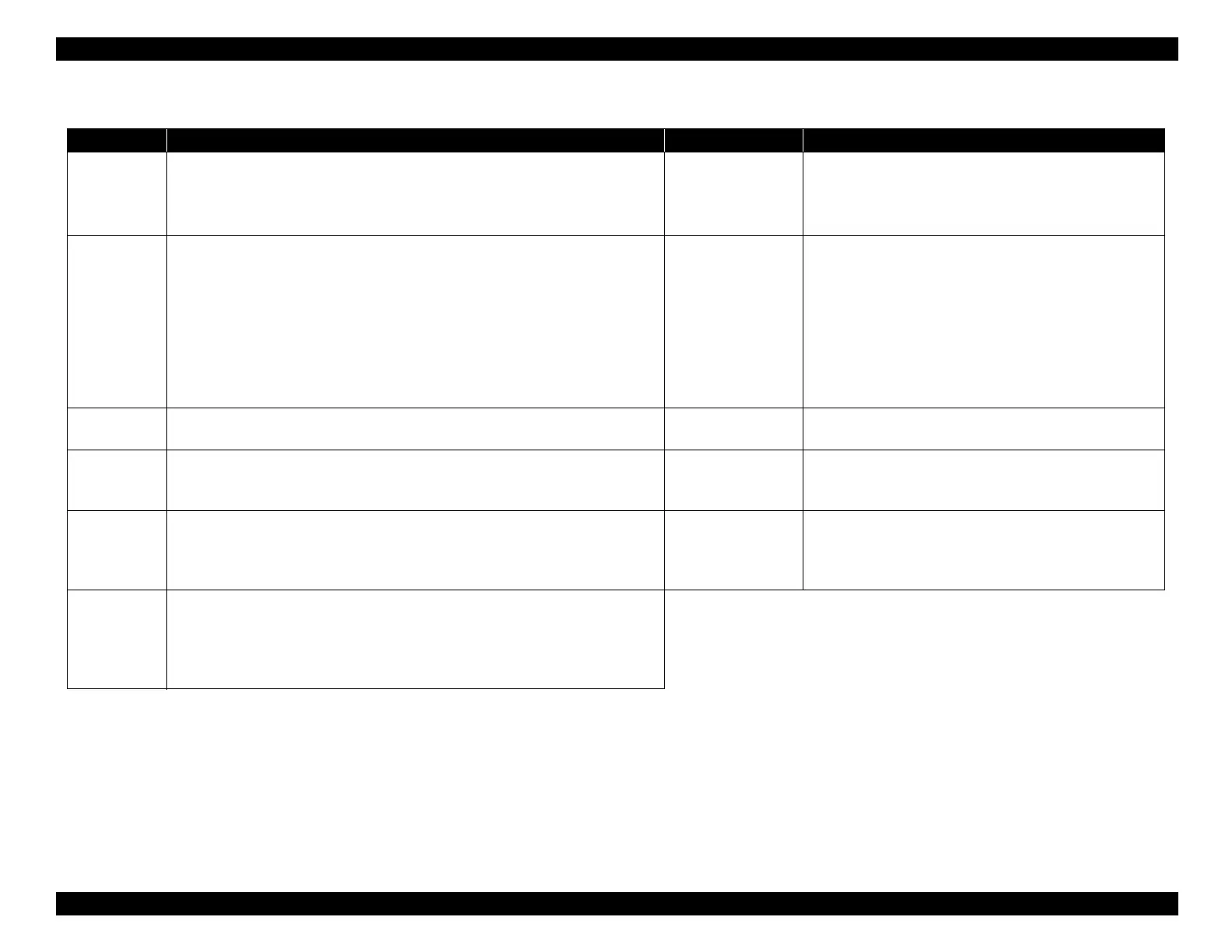

Step Check and measure Yes No

1

Check the operating environment

Check that the operating environment is within the specifications.

* Refer to 2.1 Product Hardware Specifications (P. 14)

Has the phenomenon occurred?

Go to step 2

Recommend using in an appropriate environment.

2

Check the paper

Make sure the appropriate paper has been used according to the procedure described

below.

Check that there is no damage to the paper before it pases through.

Check that the paper is in an appropriate state (no curling).

Check that using suitable paper (not paper already used for printing).

* When, for example, A4 paper is used cut to A5 size, the long grain becomes the short

grain so there is a tendency for edges to bend easily.

Make sure the appropriate paper has been used.

Go to step 3

Use suitable paper.

Use the rubbing avoidance mode.

* If the symptom continues even after using the rubbing

avoidance mode, refer to the avoidance measures.

3

Check the feed path

Check that there is no damage to or foreign object on the feed path.

Go to step 4

Remove the foreign object and then clean.

If the symptom continues to occur, go to step 4.

4

Check the Star Wheel Assy

Check that the jagged roller of the Star Wheel Assy rotates normally.

Check that there are no cuts or other damage locally on the EJ Roller surface.

Go to step 5

Replace the Star Wheel Assy (p. 439).

5

Check the PG

Check the PG with the thickness gauge and check that it is within the specified value

range (1.55 ±0.10 mm).

Is the PG within the standard value?

Contact the EPSON

Service Department.

Perform the PG Adjustment (p. 559).

If the symptom continues to occur after performing the PG

adjustment,

contact the EPSON Service Department.

Avoidance

measures

If the symptom continues even in the rubbing avoidance mode

1. Reduce the print density (default is -20 for duplex, but -5 or -10 from that).

2. Increase the drying time.

3. Make sure that a high density image does not come at the trailing edge of the first

side (rotate, change the print order, etc.).

Loading...

Loading...