EPSON WF-C5790/WF-C5790a/WF-C5710/ET-8700/WF-C5210/WF-C5290/WF-C5290a Revision A

Configuration and operating principles Operating principles 61

Confidential

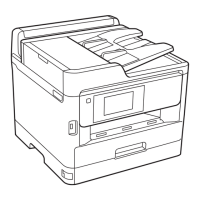

3.3.5.2 Operating principles

OVERVIEW

The inksystem mechanism of this product employs the direct acting type

1

and

consists of the carriage lock mechanism, wiper mechanism, capping

mechanism, pump mechanism, and venting valve (valve mechanism).

All the mechanisms are driven by the pump motor. The drive force of the pump

motor is transmitted to each mechanism via transmission parts, such as the

pump-drive compound gear, clutch gear, intermittent gear, cam, and drive

lever.

Additionally, this product utilize a maintenance box (waste ink pad) that retains

waste ink from the cap, with which users can replace ink themselves.

Figure 3-40. Inksystem Mechanism (Simplified Model)

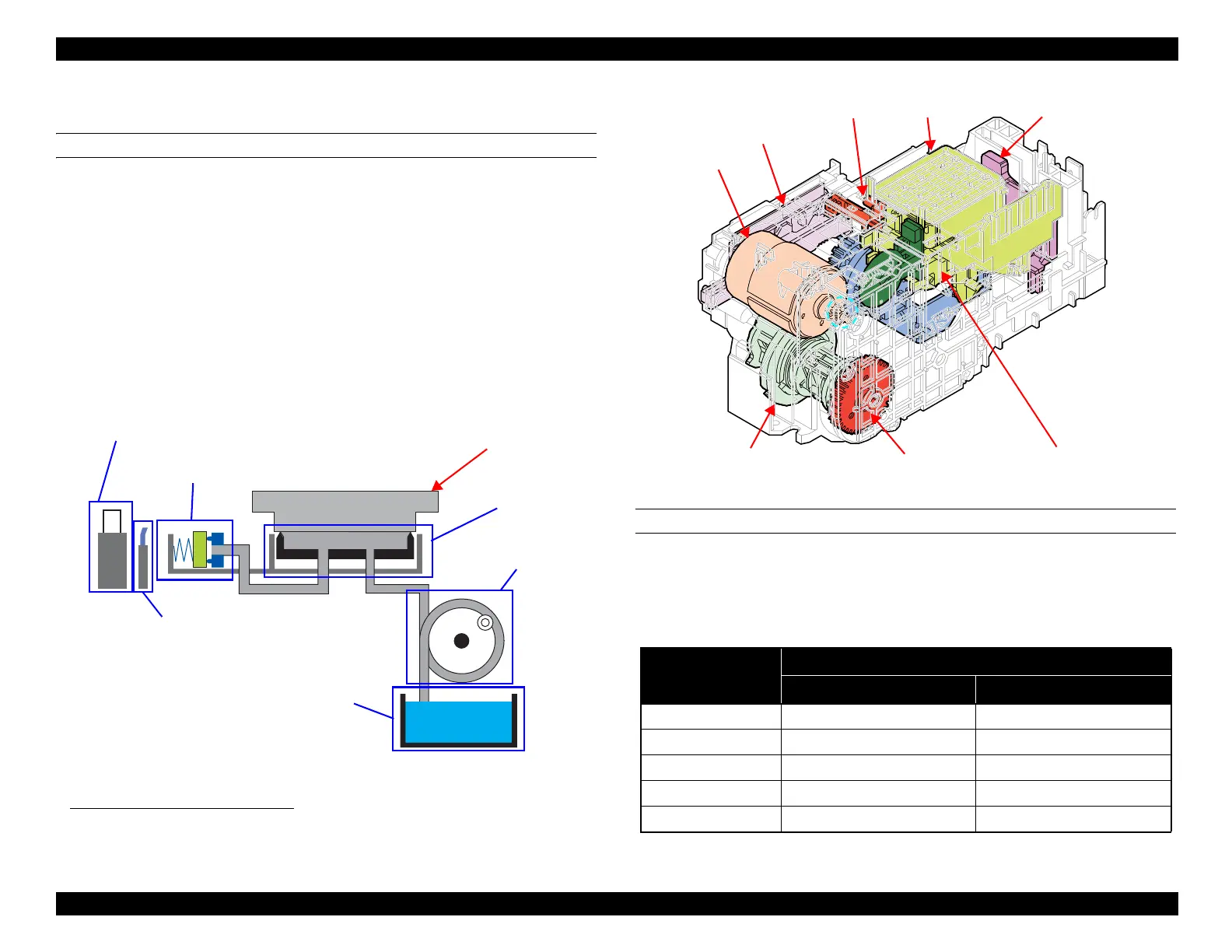

Figure 3-41. Inksystem Mechanism

DRIVE PATH

The ink system mechanism is driven by the Pump Motor. The relationship

between the Pump Motor rotational direction and operation of each part is as

follows.

1. There are two types of the capping: direct acting type and sliding type. In the direct acting type, the cap moves up and

down independently of the carriage and caps the printhead. In the sliding type, the printhead is capped (the cap is

moved up) when the carriage pushes the cap slider.

Cap mechanism

Waste ink tray

(waste ink pad)

Pump mechanism

Valve mechanism

Wiper mechanism

Carriage lock mechanism

Printhead

Table 3-22. Pump motor rotational direction and operation of the inksystem

Mechanism

Rotational direction of the Pump Motor

a

a. Rotational direction seen from output shaft

CW CCW

Wiper Wiping position Passing

Cap Drop Rise (capping)

Pump Release Suction

CR Lock Drop (CR Lock release) Rise (CR Lock set)

Venting Valve Open Close

Cap

Wiper

Carriage lock lever

Pump unit

Venting valve

Pump-drive compound gear

Pump motor

Pump encoder sensor

Loading...

Loading...